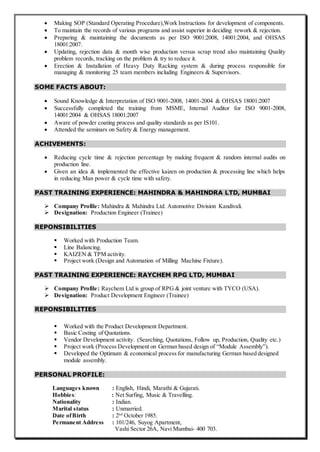

Kumar Madhukar Shinde is a production engineer with over 5 years of experience in quality assurance and production planning. He has a BE in Production Engineering and is proficient in MS Office and AutoCAD. Currently, he works as a Senior Quality Engineer at Kompress India Pvt Ltd, where he is responsible for quality assurance, quality control, work planning, scheduling, and monitoring production reports. He has expertise in implementing quality management systems and has received training in ISO 9001, ISO 14001, and OHSAS 18001.