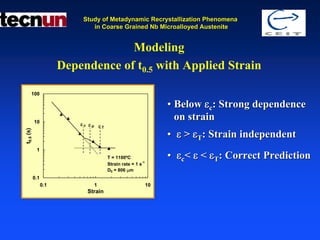

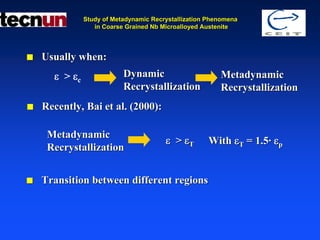

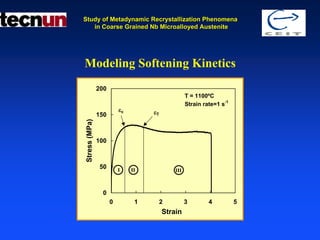

This study examines metadynamic recrystallization in coarse-grained Nb microalloyed austenite steel. There is a transition between static and metadynamic recrystallization between the critical strain εc and transition strain εT = 2.2εc. Below εc only static recrystallization occurs. Between εc and εT both static and metadynamic recrystallization contribute to softening. Above εT only metadynamic recrystallization occurs. A new model was developed that considers the contributions of both static and metadynamic recrystallization between εc and εT. The model predictions matched experimental validations

![Study of Metadynamic Recrystallization Phenomena

in Coarse Grained Nb Microalloyed Austenite

Different Softening Mechanisms

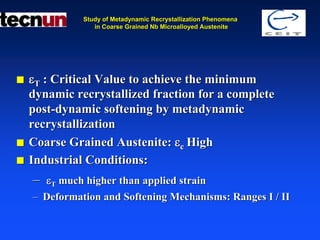

Range I (ε < εc): Static Recrystallization

– Initial Grain Size t0.5 SRX = f (D0 ,ε ,ε ,[Nb ],T )

&

– Strain

– Strain Rate

– Temperature

Range III (εΤ < ε): Metadynamic Recrystallization

– Strain Rate t0.5 MDRX = f (ε ,T )

&

– Temperature

Grain Refinement](https://image.slidesharecdn.com/mwsp02-12917244638409-phpapp01/85/Study-of-Metadynamic-Recrystallization-Phenomena-in-Coarse-Grained-Nb-Microalloyed-Austenite-10-320.jpg)