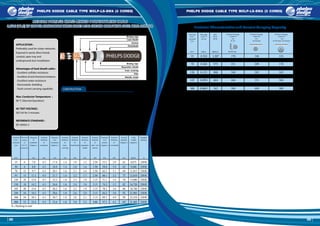

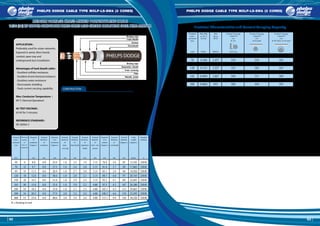

Phelps Dodge International (Thailand) Limited is a leading manufacturer of medium and high voltage power cables. It has state-of-the-art facilities in Thailand that can produce cables rated up to 245kV. The company uses high quality materials and stringent quality control processes to ensure reliable cables that meet international standards. It has extensive experience in manufacturing cables for power distribution systems.