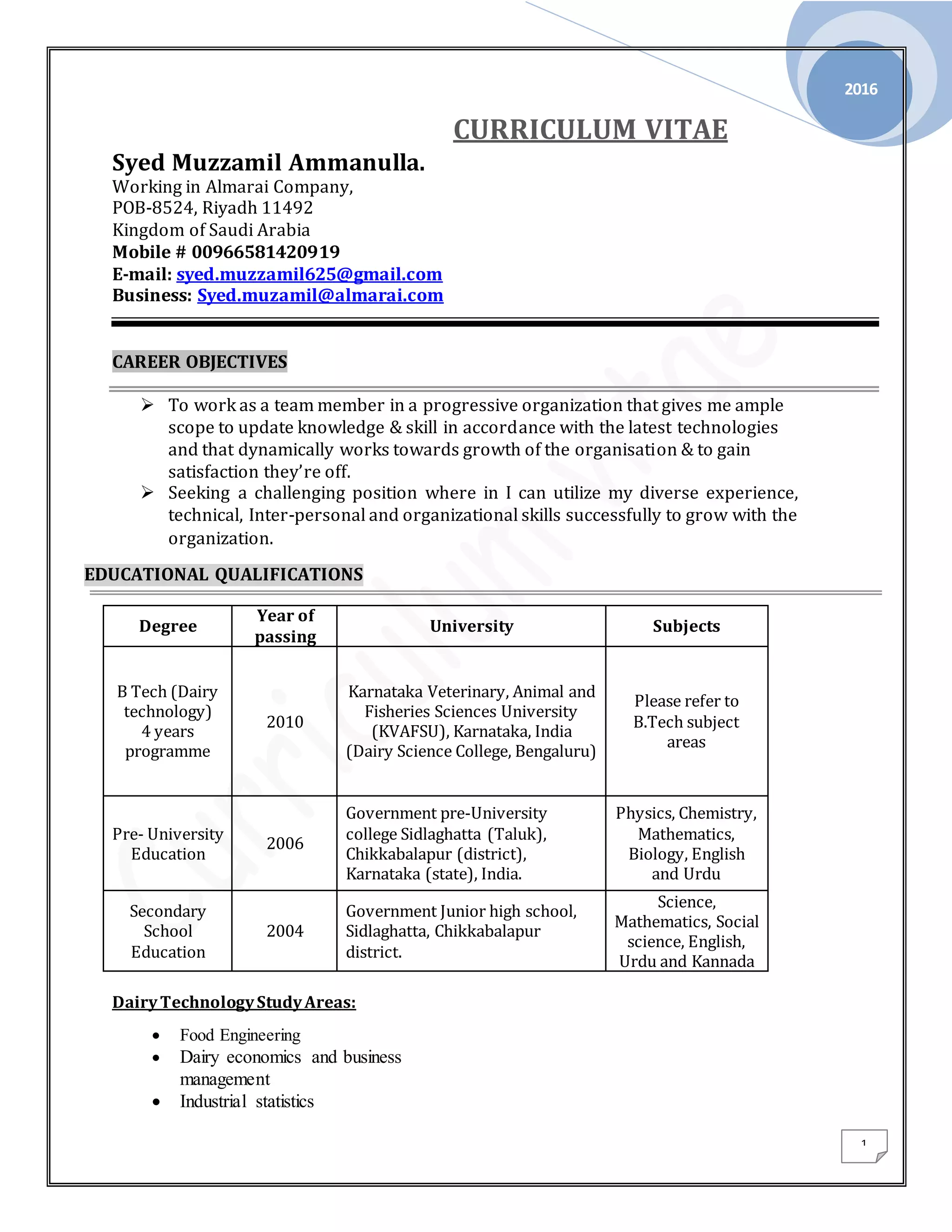

This curriculum vitae outlines the educational and professional experience of Syed Muzzamil Ammanulla. He received a B.Tech in Dairy Technology from Karnataka Veterinary, Animal and Fisheries Sciences University in 2010. He has over 5 years of experience working in quality roles for Almarai, the largest dairy company in the Middle East. Currently he is a Senior Team Manager in the Quality Systems department at Almarai's Central Processing Plant 1. His responsibilities include HACCP planning and food safety programs. He has been involved in several projects commissioning new processing equipment.