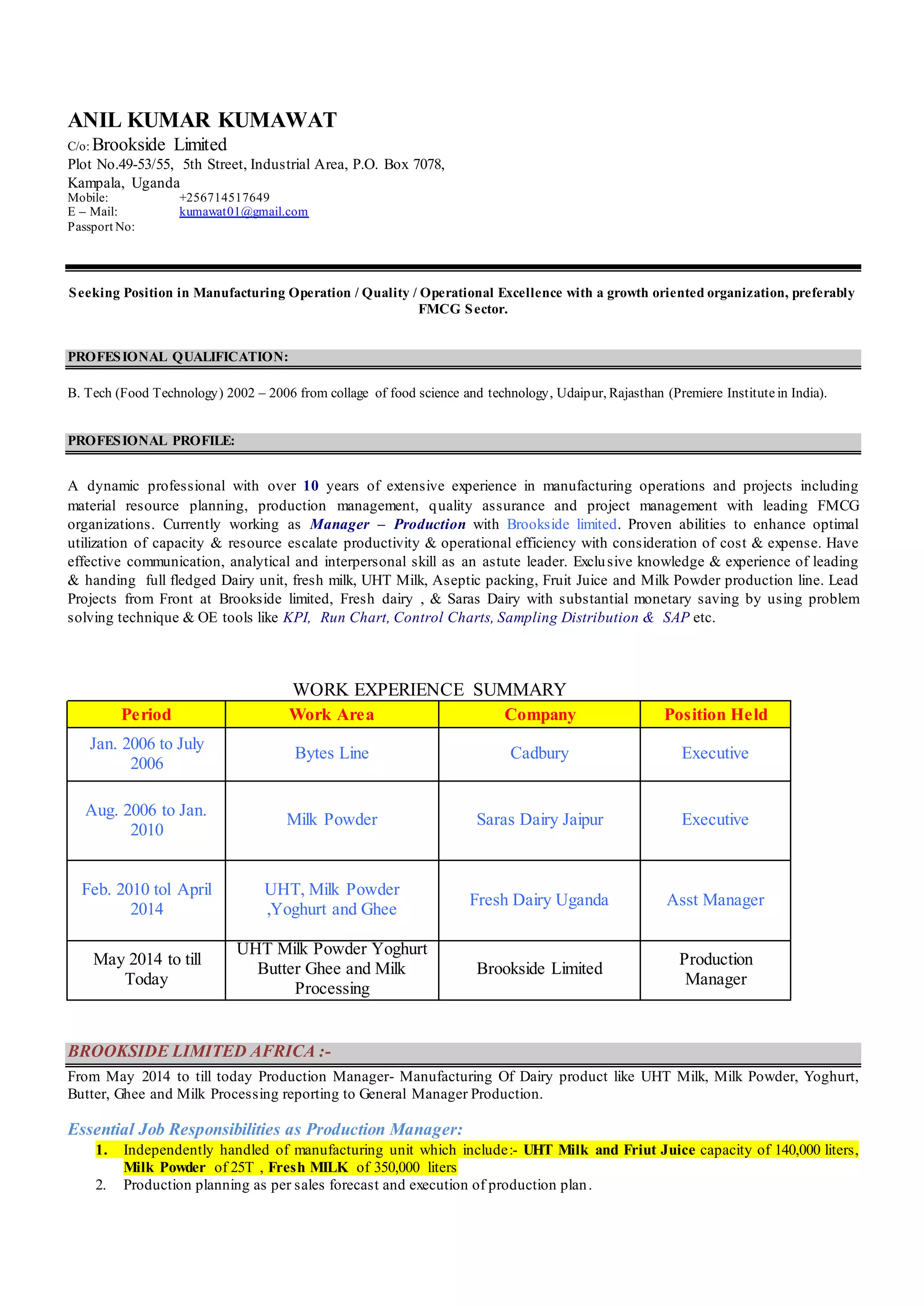

Anil Kumar Kumawat is seeking a position in manufacturing, quality or operational excellence, preferably in the FMCG sector. He has over 10 years of experience in production management and quality assurance with leading companies in India and Uganda. Currently he is the Production Manager at Brookside Limited in Uganda, where he is responsible for dairy production lines with a capacity of 140,000 liters of UHT milk and 25 tons of milk powder.