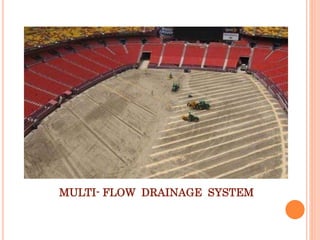

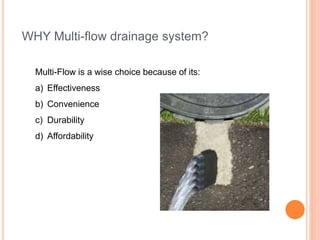

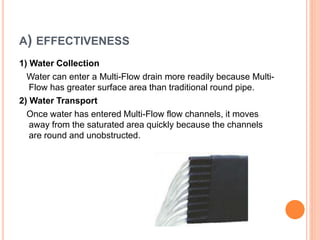

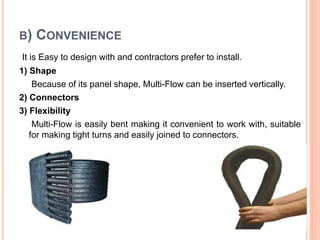

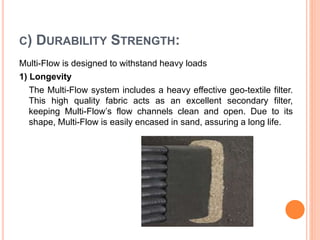

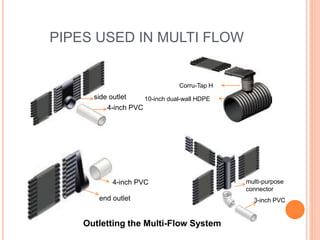

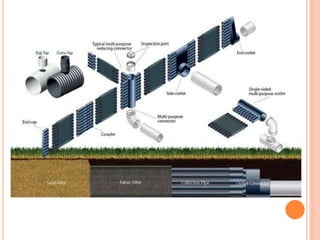

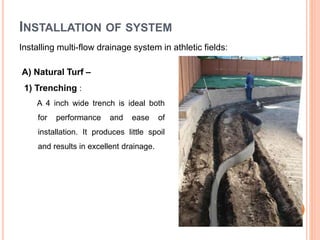

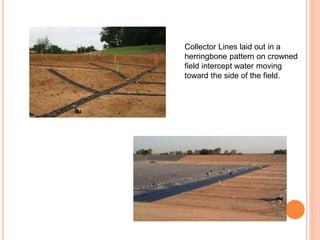

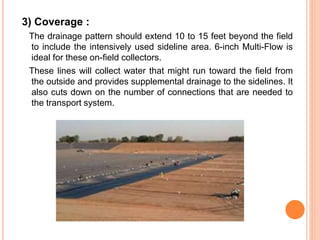

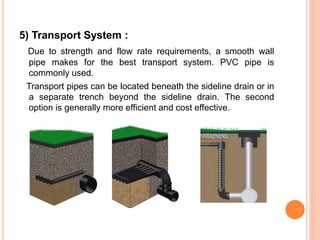

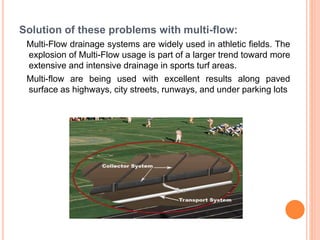

This presentation discusses the multi-flow drainage system. It introduces multi-flow as a geo-composite drainage system made of HDPE drain pipes wrapped in geotextile fabric. The objectives are to prevent waterlogging, reuse stormwater, and ensure efficient soil drainage. Multi-flow is effective due to its water collection and transport abilities. It is convenient to install due to its panel shape and flexible connectors. When installing for athletic fields, collector lines are laid out and spaced 10-15 feet apart with a transport system to remove water. Proper installation and backfilling with sand is important. The multi-flow system addresses drainage problems in fields and paved surfaces.