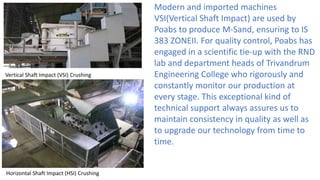

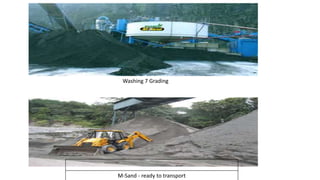

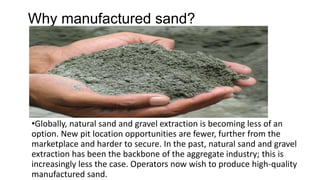

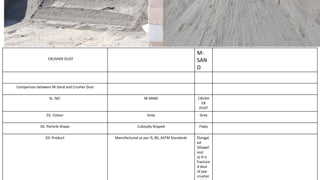

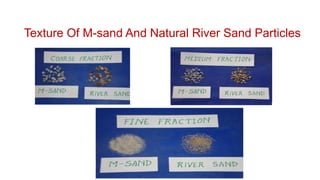

M-sand, or manufactured sand, is a high-quality alternative to river sand produced from crushed granite, ensuring consistent grading and free from impurities such as clay and silt. Its superior quality adheres to international standards and is backed by scientific testing, making it increasingly favored by builders due to its better strength properties. As natural sand resources diminish globally, m-sand is becoming essential in the construction industry.