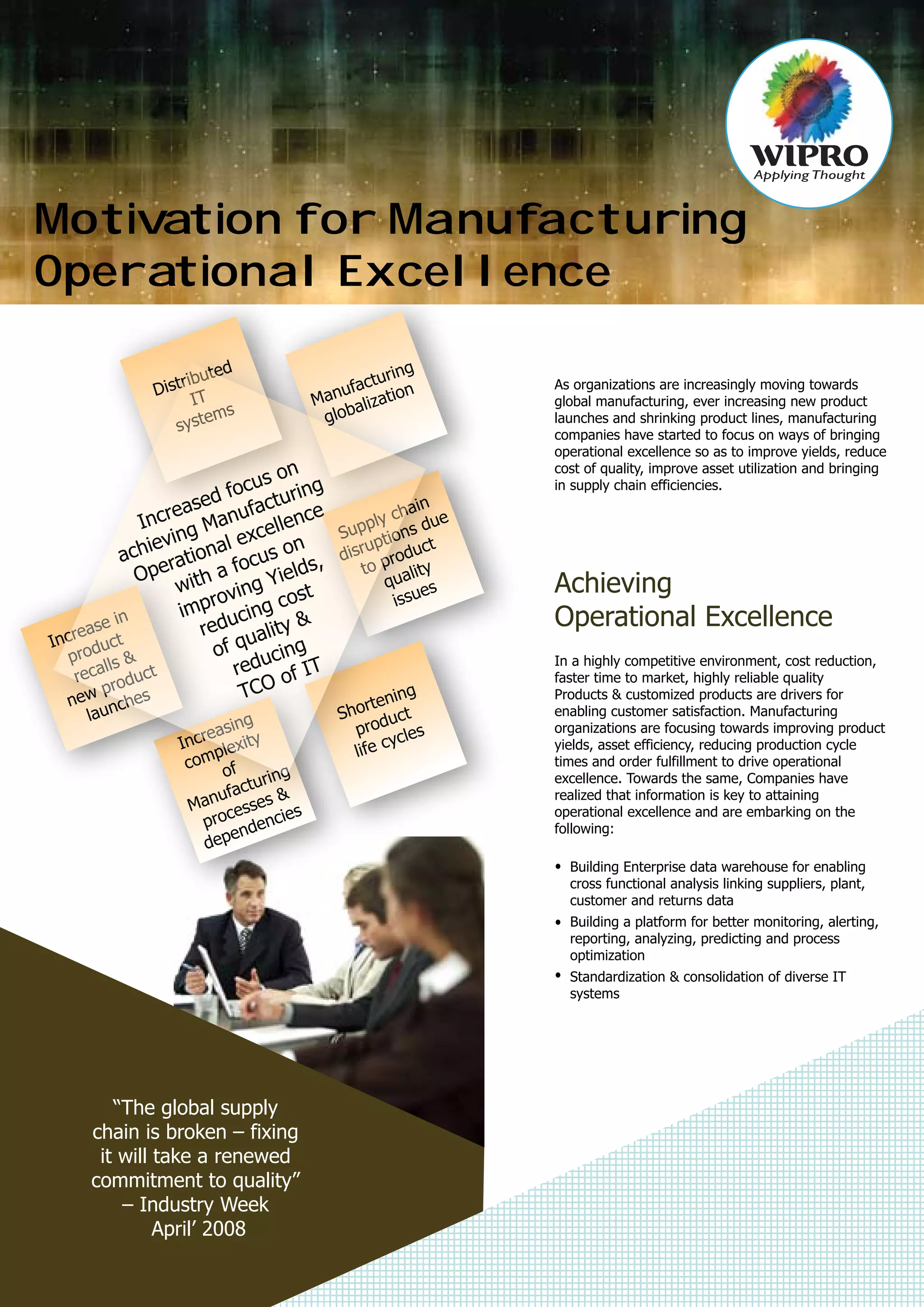

The document discusses the increasing focus on achieving manufacturing operational excellence in the face of challenges like globalization, complex supply chains, and short product lifecycles. It outlines how companies are building enterprise data warehouses and standardizing IT systems to gain insights from data linking suppliers, plants, customers and returns. Wipro is highlighted as offering a quality lifecycle analysis solution powered by SAS to help companies improve yields, reduce costs and enhance customer experience by aggregating machine, test and audit data to surface issues and accelerate problem solving.