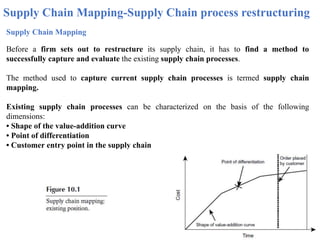

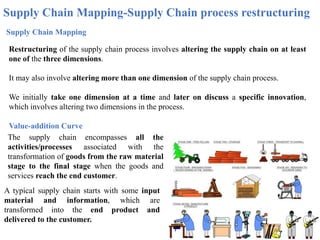

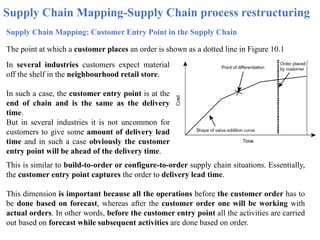

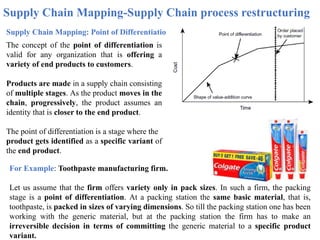

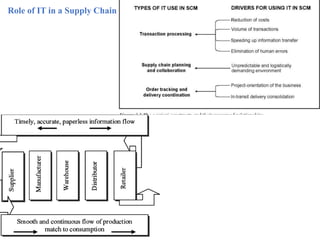

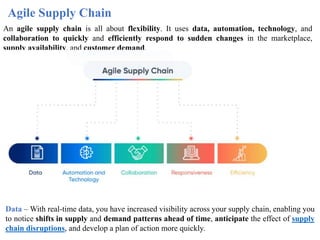

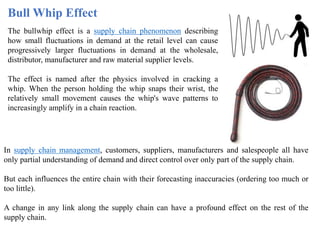

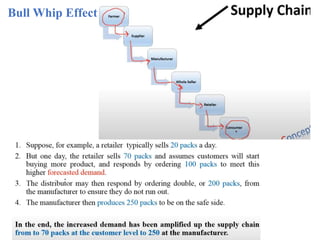

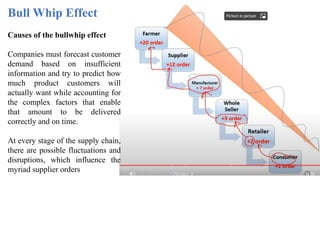

This document discusses various topics related to supply chain management including current trends in supply chain integration, building partnerships and trust within the supply chain, the bullwhip effect, effective forecasting, coordinating the supply chain, supply chain restructuring, supply chain mapping, postponing the point of differentiation, the role of information technology in the supply chain, agile supply chains, and the future of information technology in supply chain management.