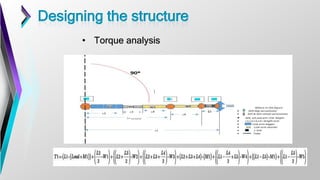

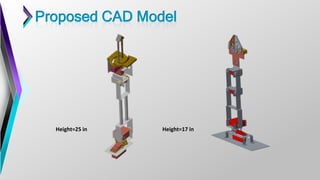

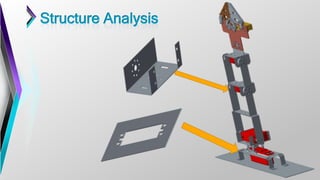

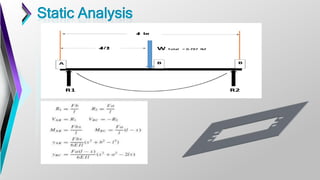

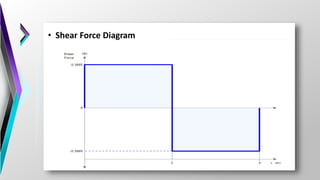

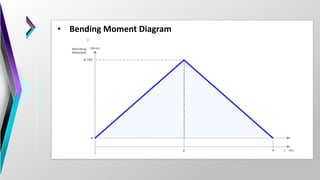

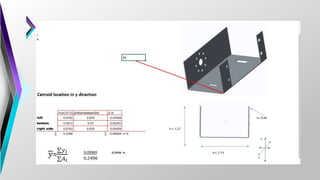

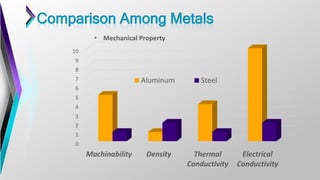

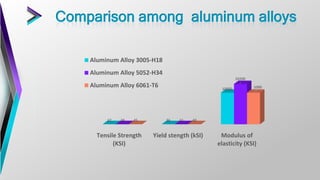

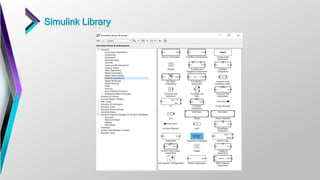

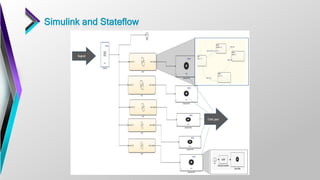

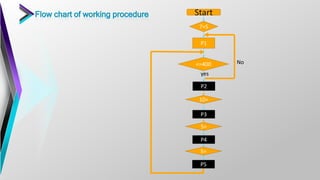

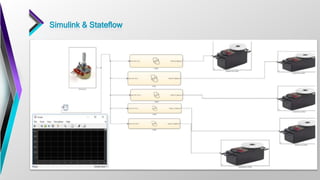

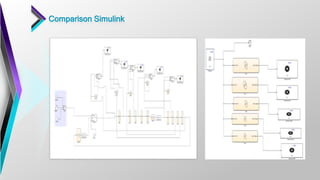

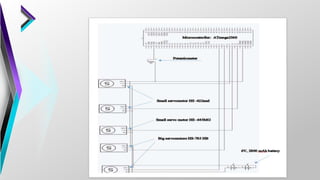

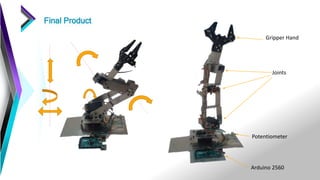

The document describes the design and development of a model robotic arm with 3 joints and 4 degrees of freedom. It discusses the design requirements, structural design using CAD modeling, torque analysis of servomotors, material selection of aluminum alloy, and programming of the arm using Matlab Simulink and Stateflow for control. The arm is controlled with an Arduino Mega 2560 microcontroller.