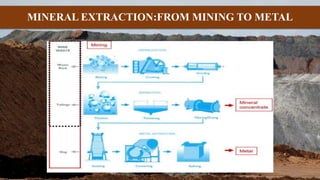

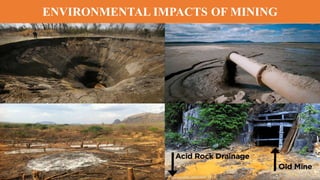

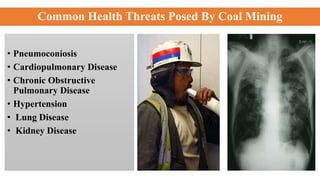

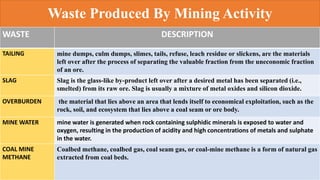

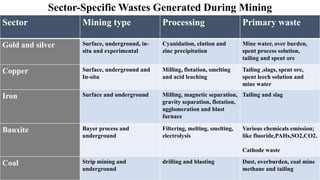

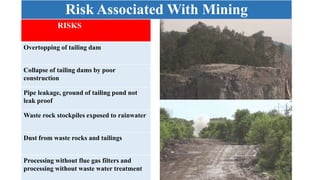

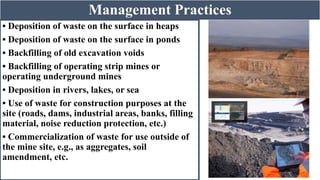

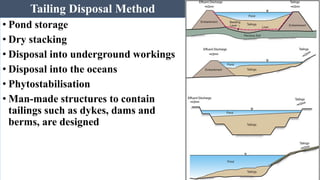

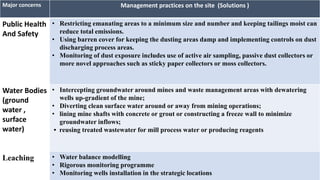

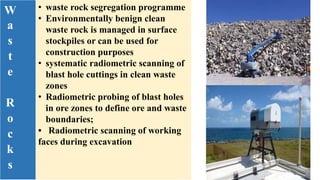

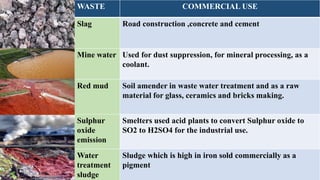

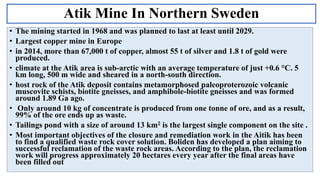

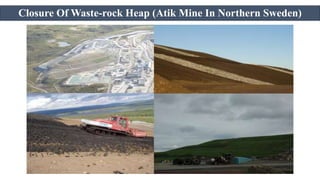

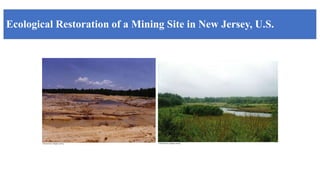

This document summarizes information about mining waste and its management. It discusses different types of mining and waste produced, including tailings, slag, overburden, and mine water. It describes environmental impacts and health threats of mining as well as sector-specific wastes. The document outlines management practices for waste such as deposition, backfilling, and commercial use. Major concerns regarding public health, water, and leaching are addressed. An example of waste management at the Atik copper mine in Sweden is provided, along with conclusions on the role and impacts of mining.