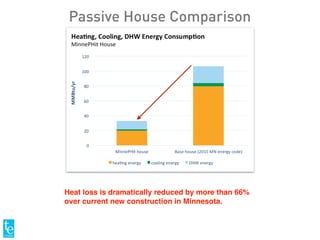

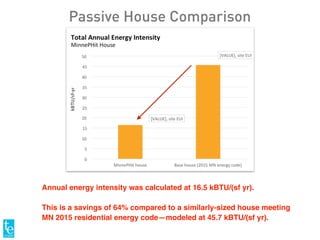

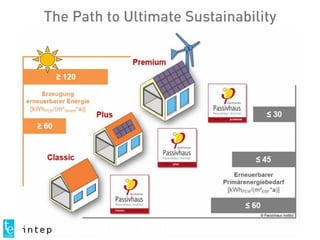

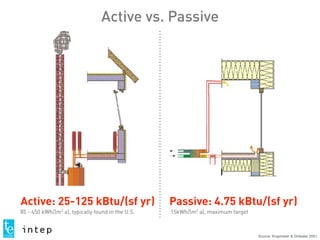

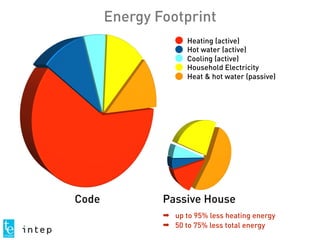

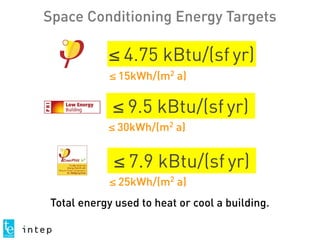

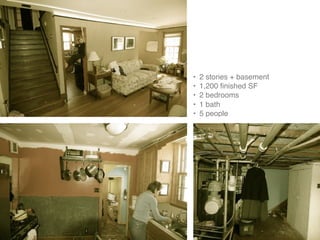

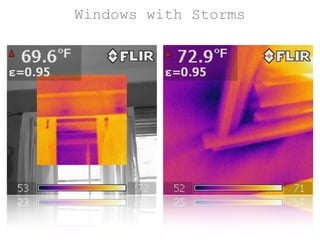

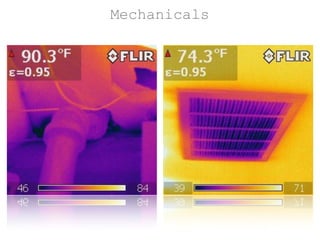

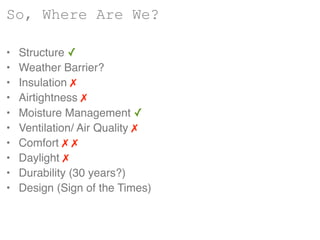

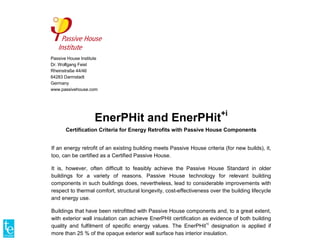

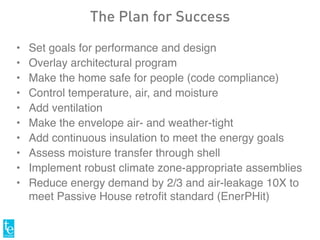

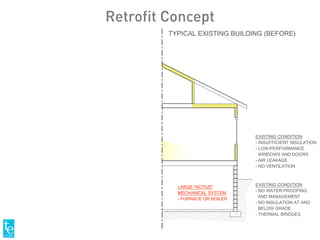

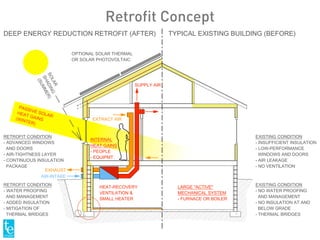

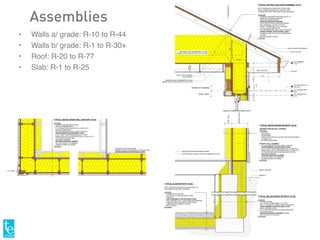

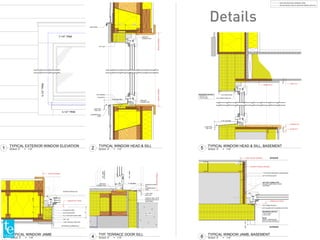

The document presents a case study of the Minnephit House, the first cold-climate EnerPHit project, emphasizing passive house standards for energy efficiency in retrofitting residential buildings. It outlines goals for performance, design, construction details, and provides energy modeling metrics alongside challenges and strategies for achieving passive house certification in existing structures. The results demonstrate significant energy savings and improvements in indoor comfort while meeting sustainability standards.

![Airtightness

Initial Test

8.5 ACH50 [2,100 CFM50]](https://image.slidesharecdn.com/2017dedcminnephitcasestudytimeian-170501003733/85/MinnePHit-House-Case-Study-52-320.jpg)

![Rough-In Test

0.87 ACH50 [267 CFM50]≤1.0 Airtightness](https://image.slidesharecdn.com/2017dedcminnephitcasestudytimeian-170501003733/85/MinnePHit-House-Case-Study-126-320.jpg)

![Final Test

0.65 ACH50 [195 CFM50]≤1.0 Airtightness](https://image.slidesharecdn.com/2017dedcminnephitcasestudytimeian-170501003733/85/MinnePHit-House-Case-Study-166-320.jpg)

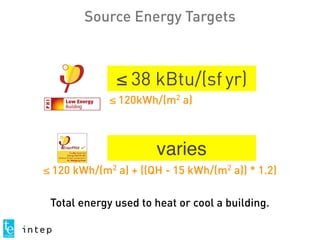

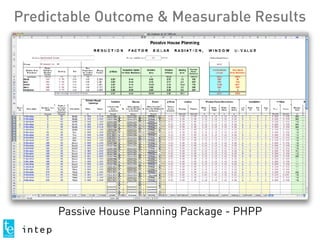

![Specific Primary Energy Demand

112 kWh/m2 a [35.5 kBTU/ft² a]

Component Approach

Minimum R-values throughout

Heating Load

20 W/m2 [6.3 Btu/h/ft²]

4.1 kW [14 kBtu/h]

≤130QP ≤ 120 kWh/m2a + ((QH - 15 kWh/(m2a)) * 1.2)

Airtightness

0.65 ACH50 [196 CFM50] ≤1.0

Cooling Load

2.6 kW

[0.74 tons, 8.8 kBtu/h]

Passive House Performance](https://image.slidesharecdn.com/2017dedcminnephitcasestudytimeian-170501003733/85/MinnePHit-House-Case-Study-167-320.jpg)