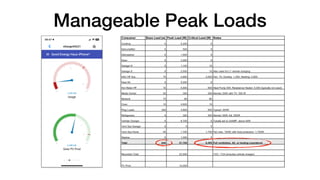

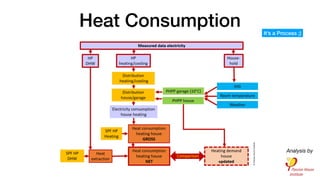

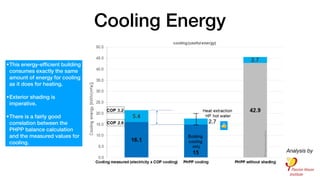

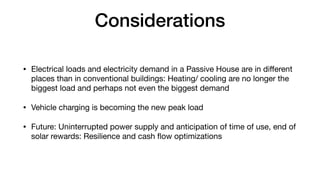

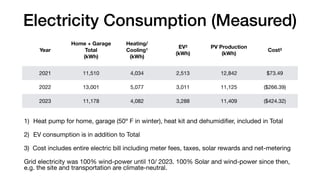

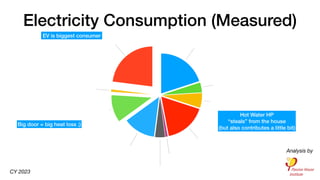

The document details the design and implementation of a certified Passive House Plus in Minneapolis, focusing on electrification for climate neutrality using renewable energy sources. It discusses construction specifics, energy efficiency measures, and the integration of heat pumps and electric vehicles, highlighting both challenges and successes related to energy consumption and grid reliance. The project aims for a net-zero energy balance annually, promoting an all-electric lifestyle in a cold climate zone.

![Minneapolis, Minnesota, USA

US Climate Zone 6 (very cold)

About 8,000 HDD

Design temp: -31º C [-24º F]

richardleonardschultz.com](https://image.slidesharecdn.com/2024-11-06gehelectrifyresponsiblytestudio-241107160206-0abc5f31/85/Electrify-Responsibly-with-Passive-House-Plus-10-320.jpg)

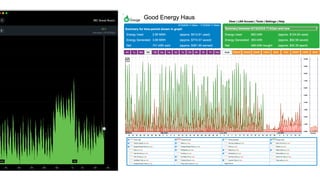

![Electricity Consumption (Home)

Electricity

[kWh/

a]

0

500

1000

1500

2000

2500

3000

2023 - Consumer

Dehumidi

fi

er Network Ventilation Hot Water HP Appliances Heat/ Cool House Plugs, Lights

1,961

2,417

1,901

813

546

633

74

4.1 kWh/ m2 a

12.4 kWh/ m2 a

Analysis by

CY 2023](https://image.slidesharecdn.com/2024-11-06gehelectrifyresponsiblytestudio-241107160206-0abc5f31/85/Electrify-Responsibly-with-Passive-House-Plus-37-320.jpg)