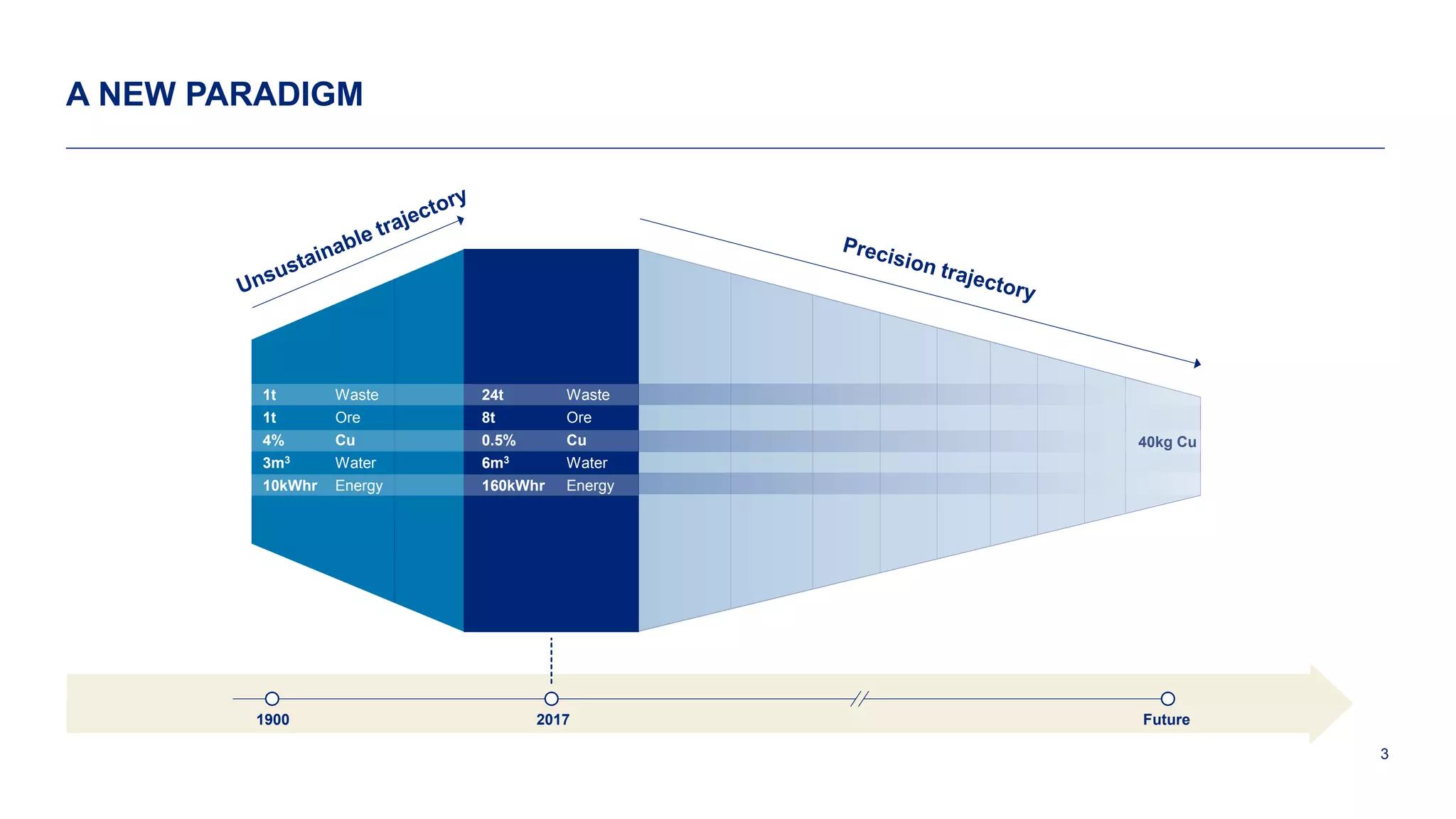

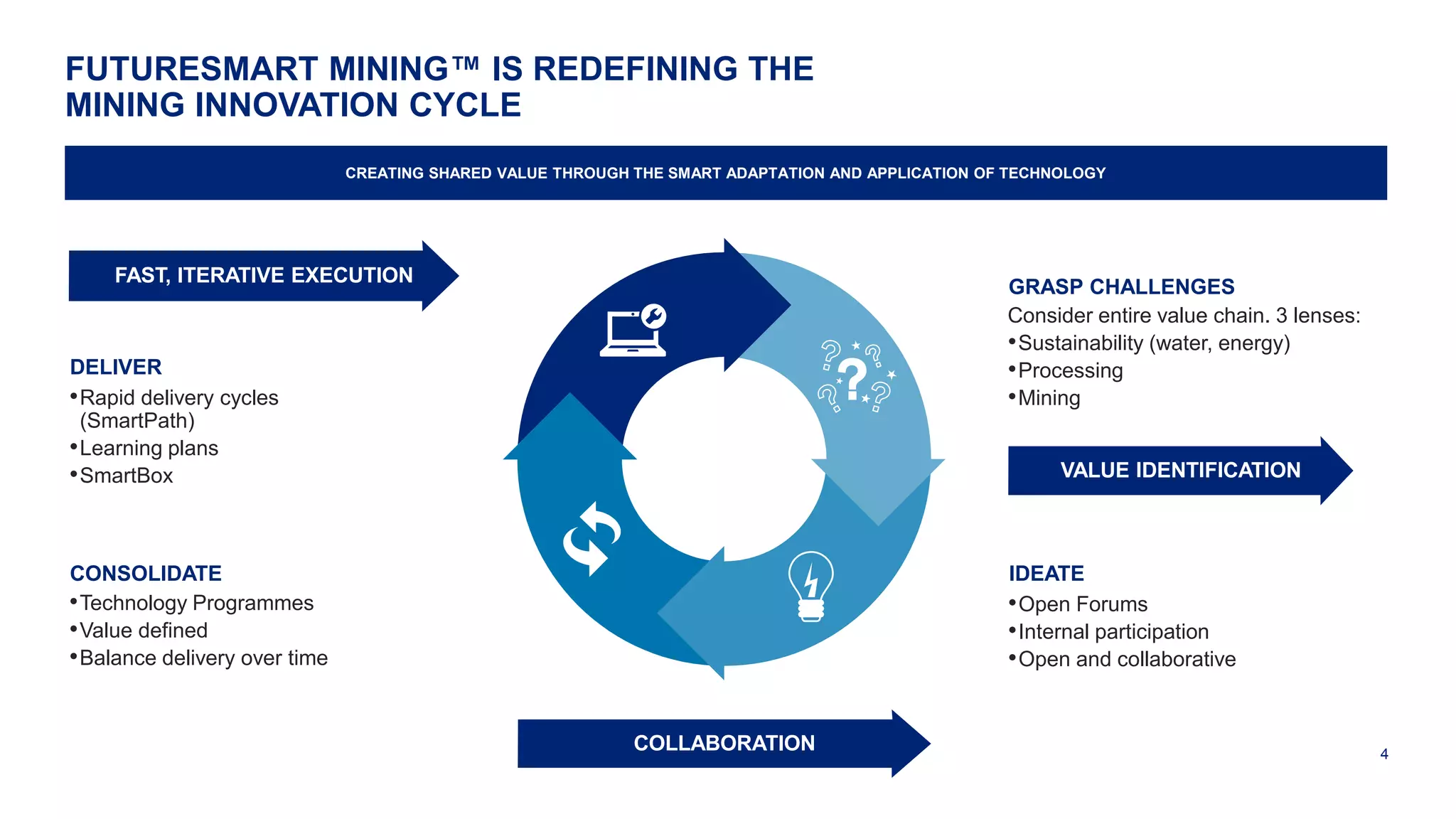

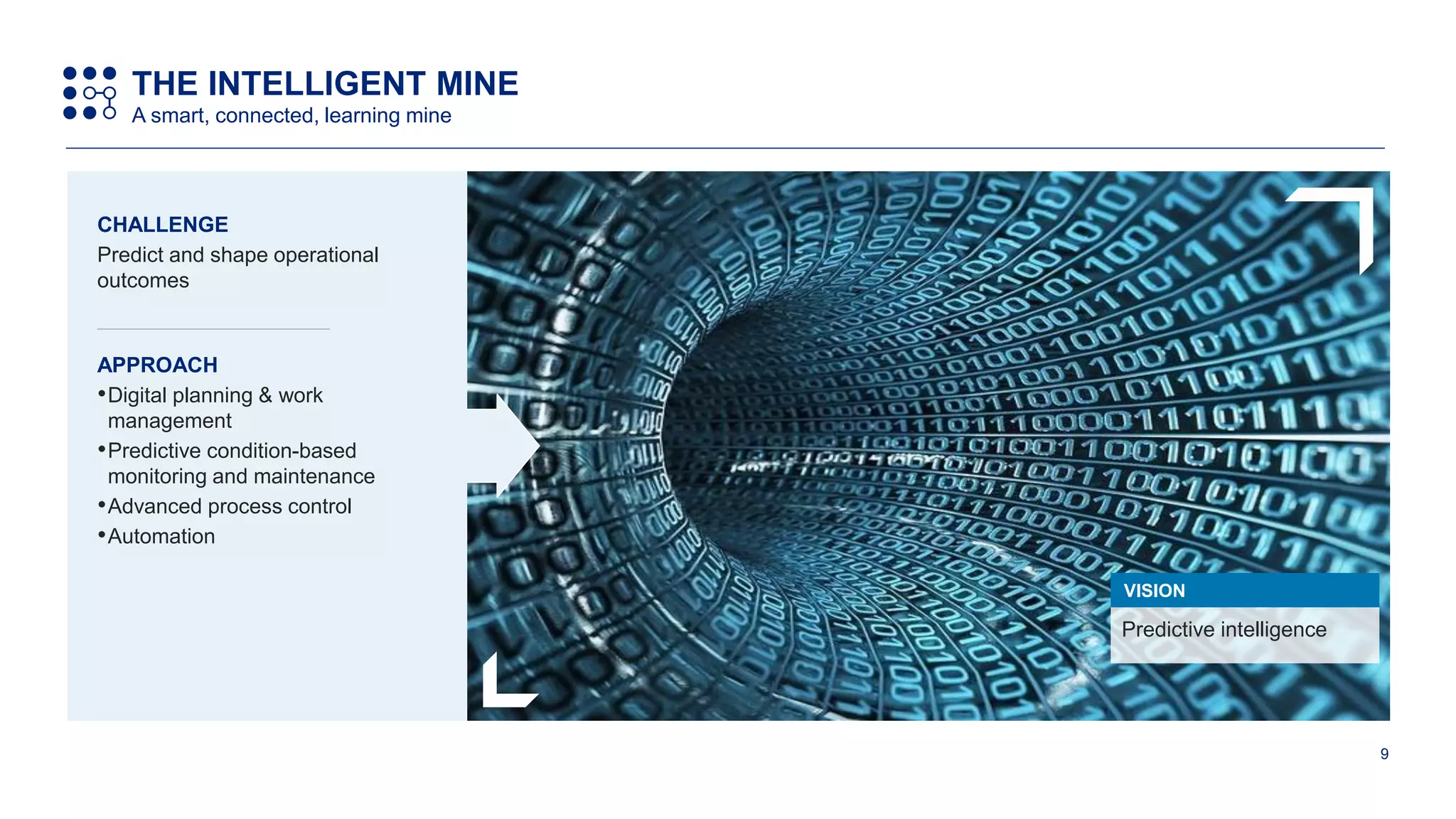

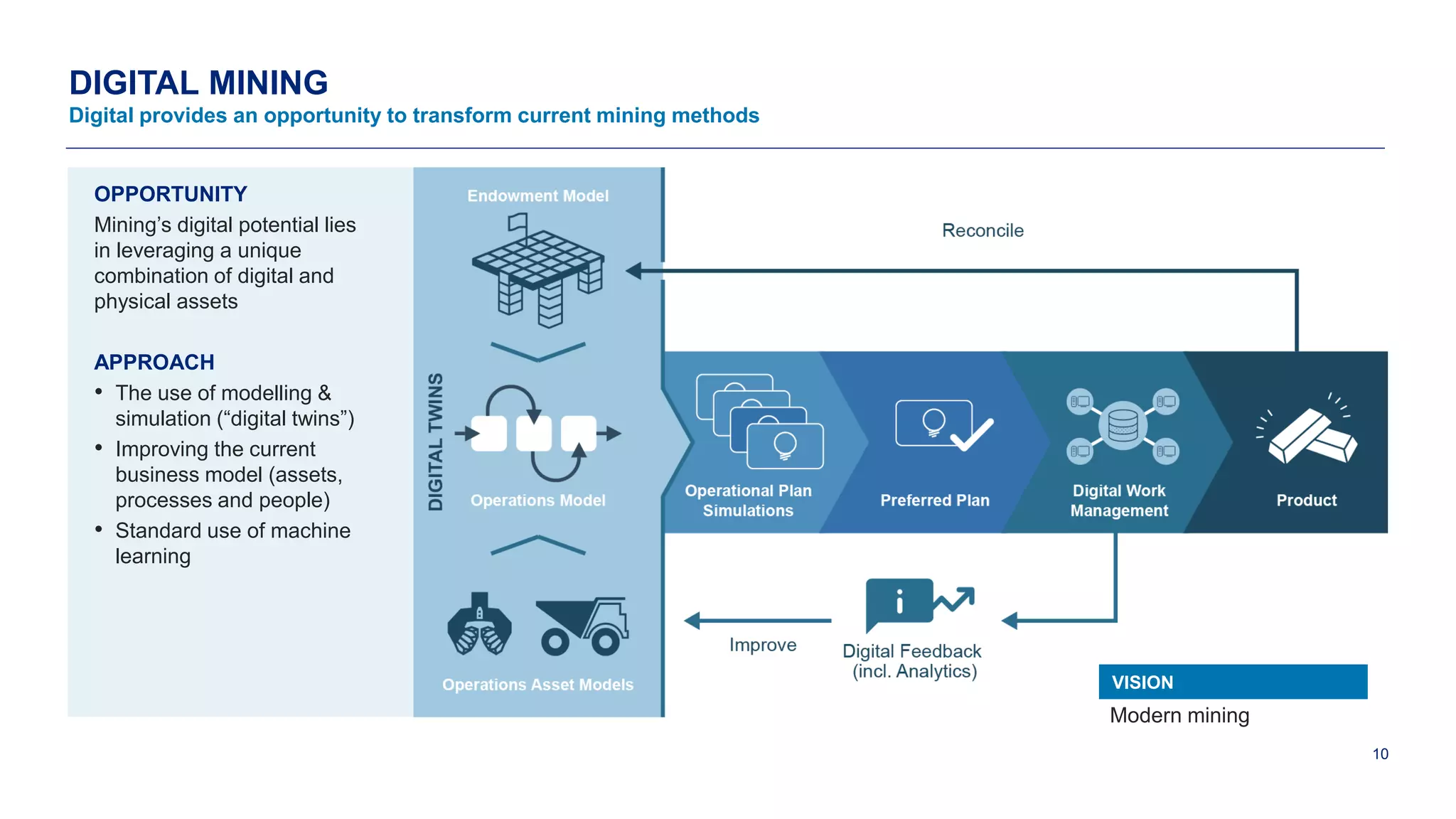

Anglo American's Futuresmart MiningTM initiative is aimed at innovating the mining industry by addressing key challenges in safety, productivity, and sustainability through a transformation in technology and operational practices. This includes concepts such as precision mining, waterless processing, and the integration of digital tools for predictive intelligence and enhanced efficiency. The goal is to create a smart, connected, and learning mining environment that reduces waste and leverages digital innovation to redefine the future of mining.