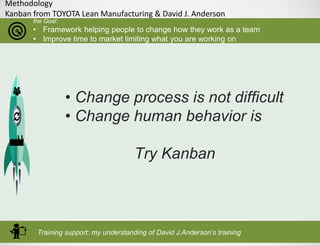

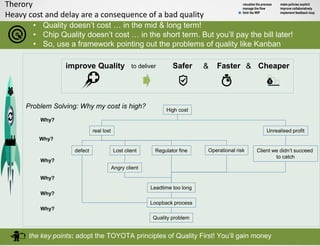

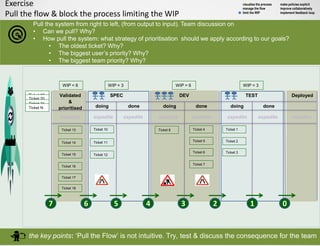

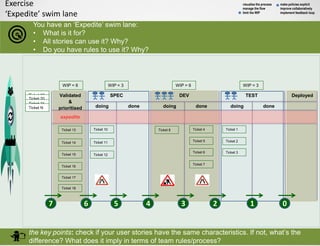

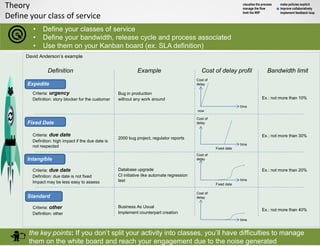

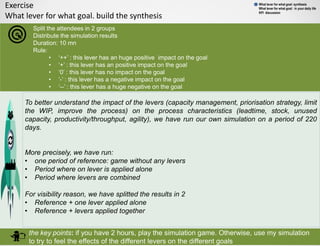

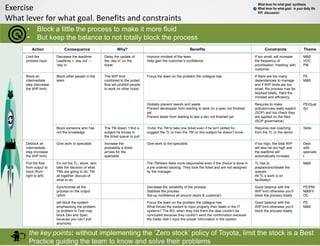

This document provides an overview of Kanban methodology based on Toyota Lean Manufacturing principles and the training approach of David J. Anderson. The goals of Kanban include improving time to market, limiting work in progress, and changing human behavior through process changes. The document outlines why and how to manage change using Kanban and provides definitions and objectives of Kanban training. It discusses the six core Kanban practices of visualizing the process, managing flow, limiting WIP, making policies explicit, implementing feedback loops, and improving collaboratively. Examples and exercises are provided to illustrate applying these practices through visualizing workflows, identifying bottlenecks, pulling work, and defining classes of service. The key points emphasize applying Lean principles like quality first and managing