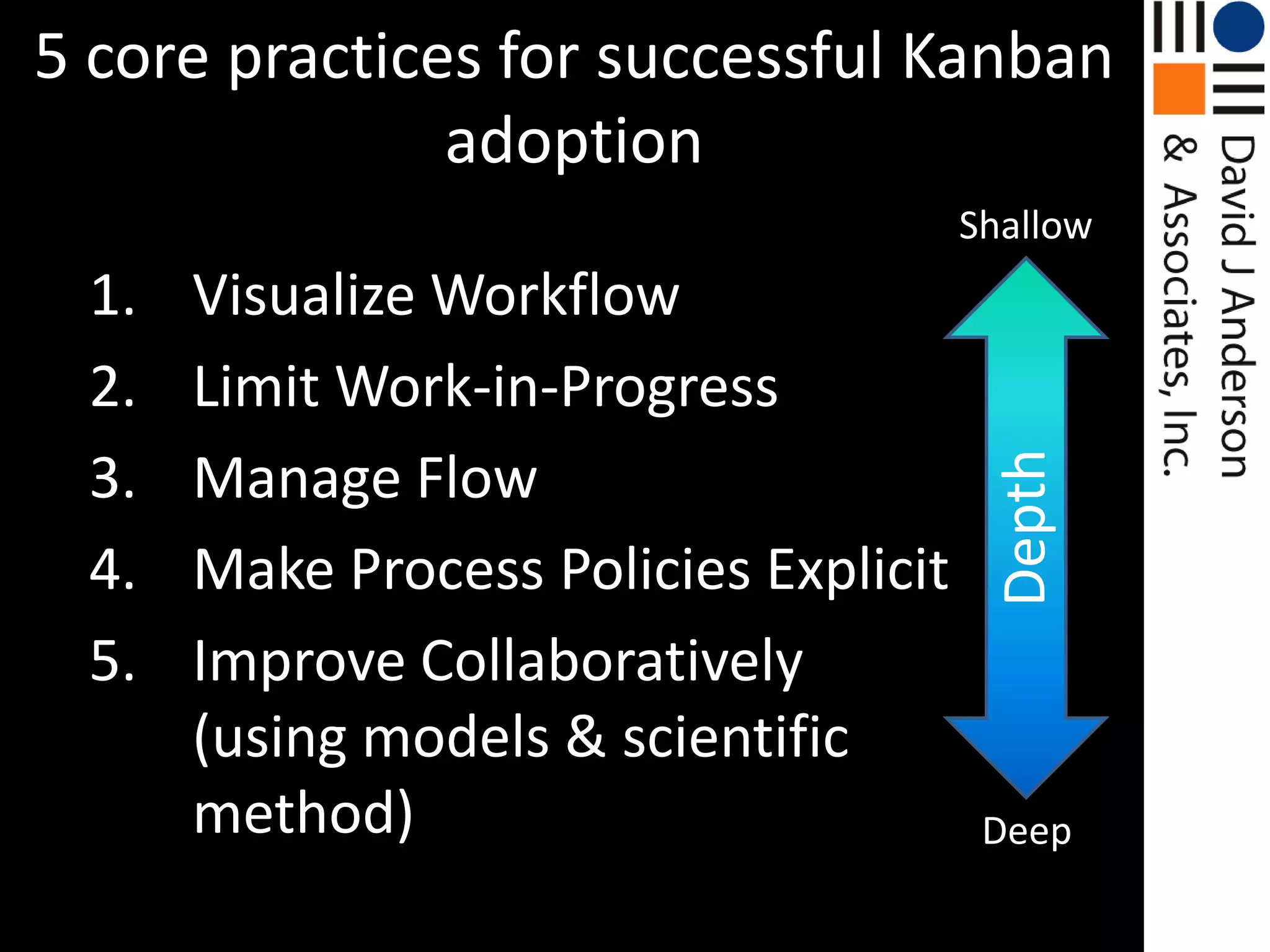

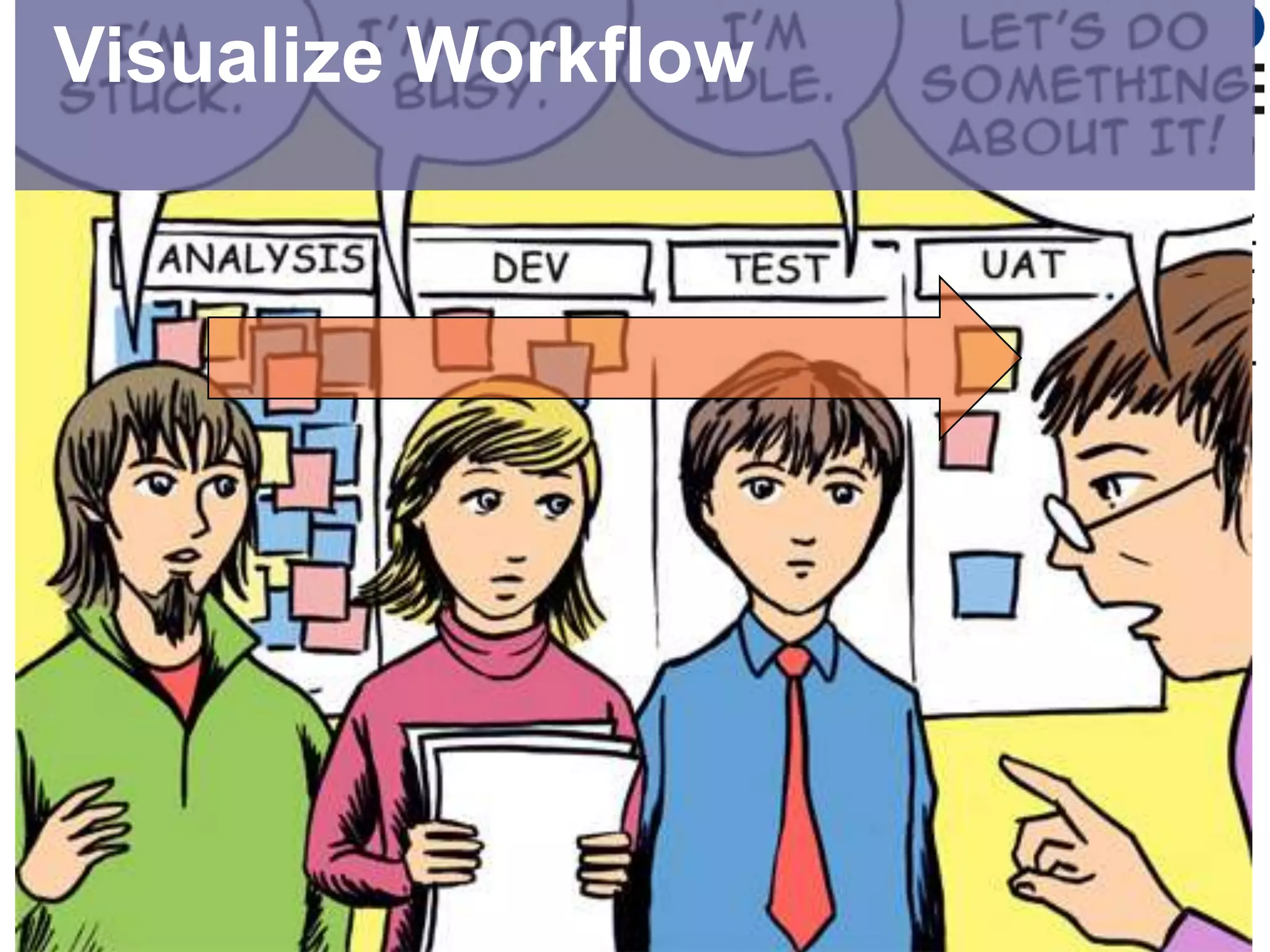

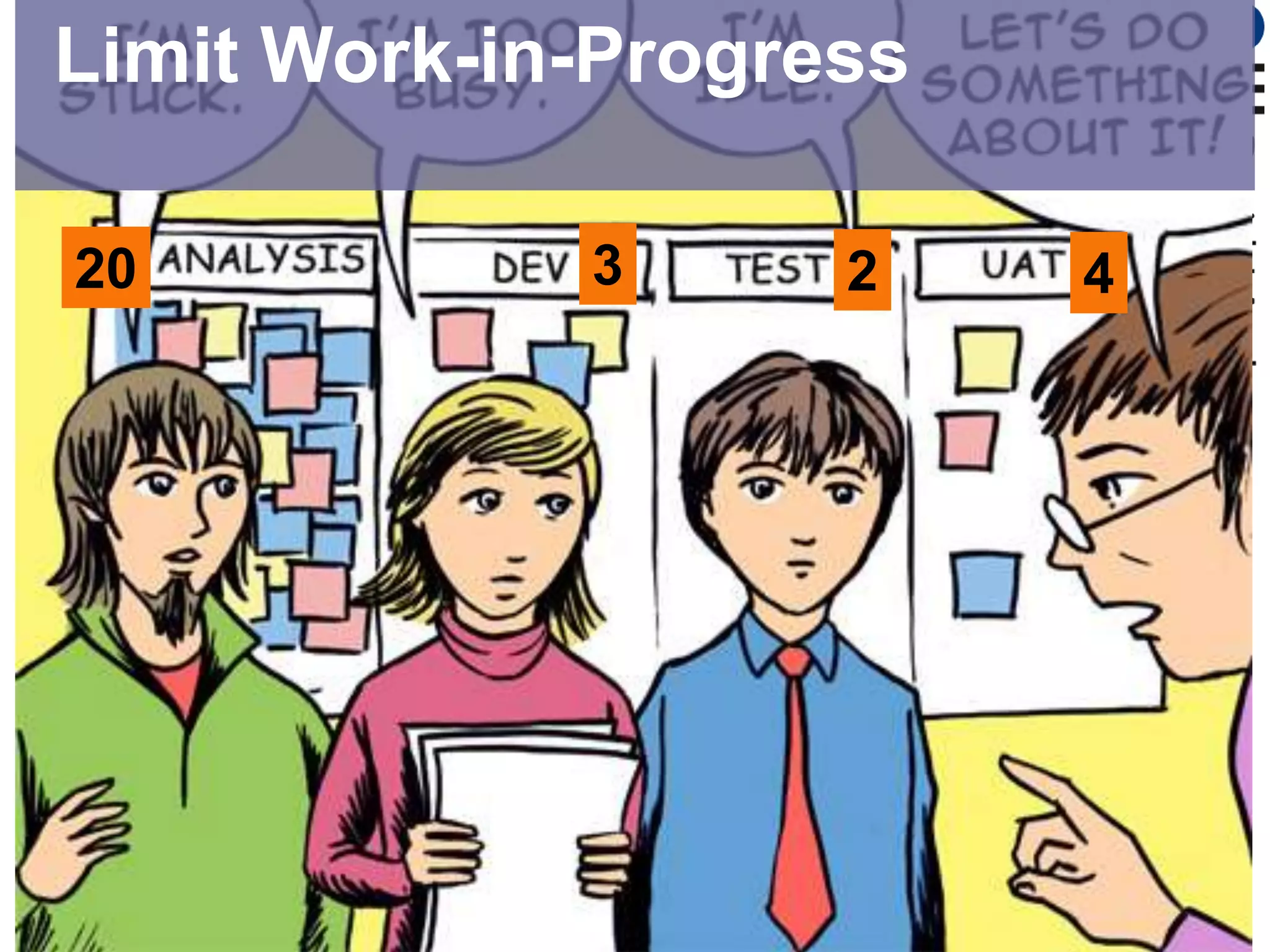

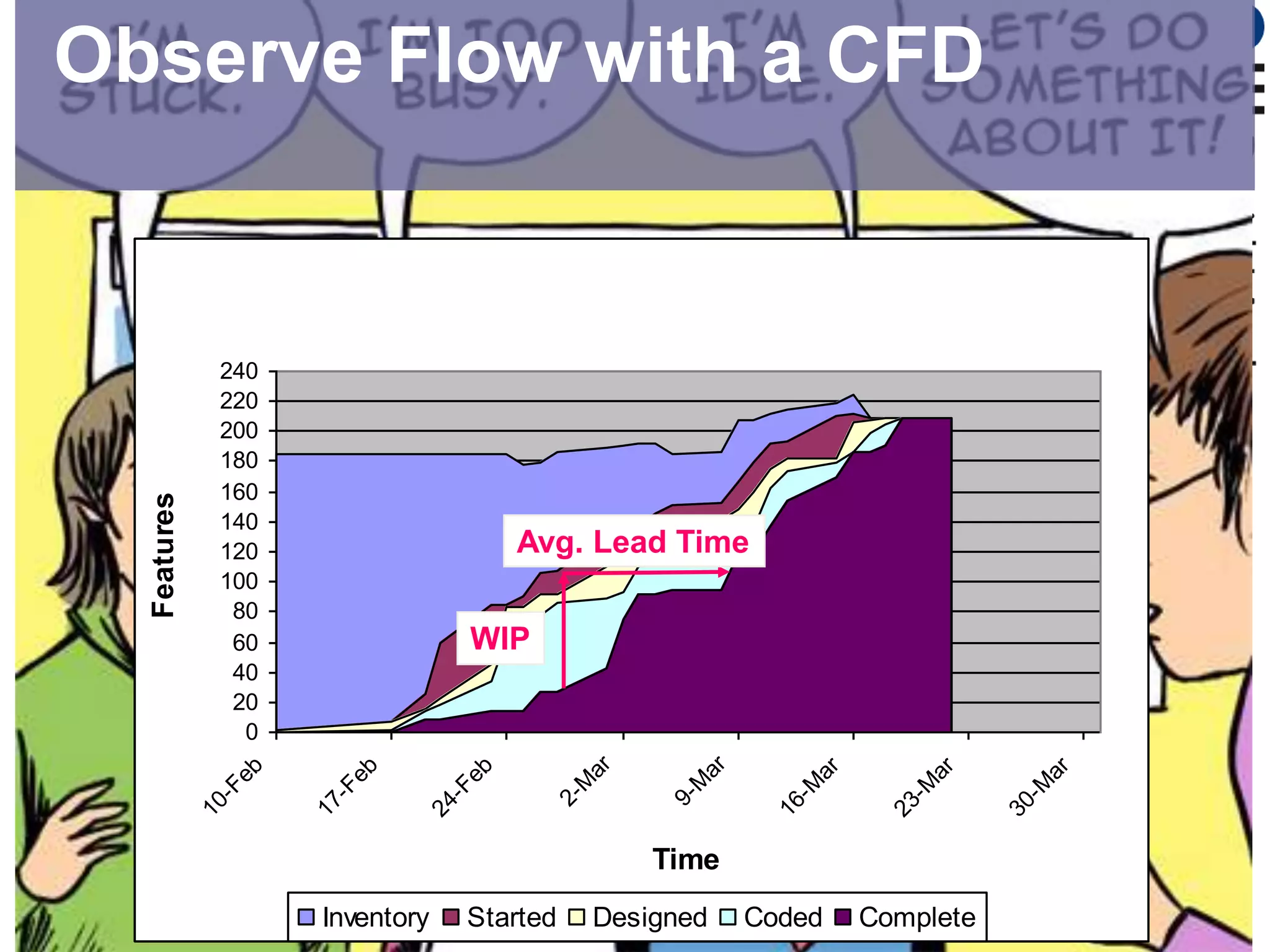

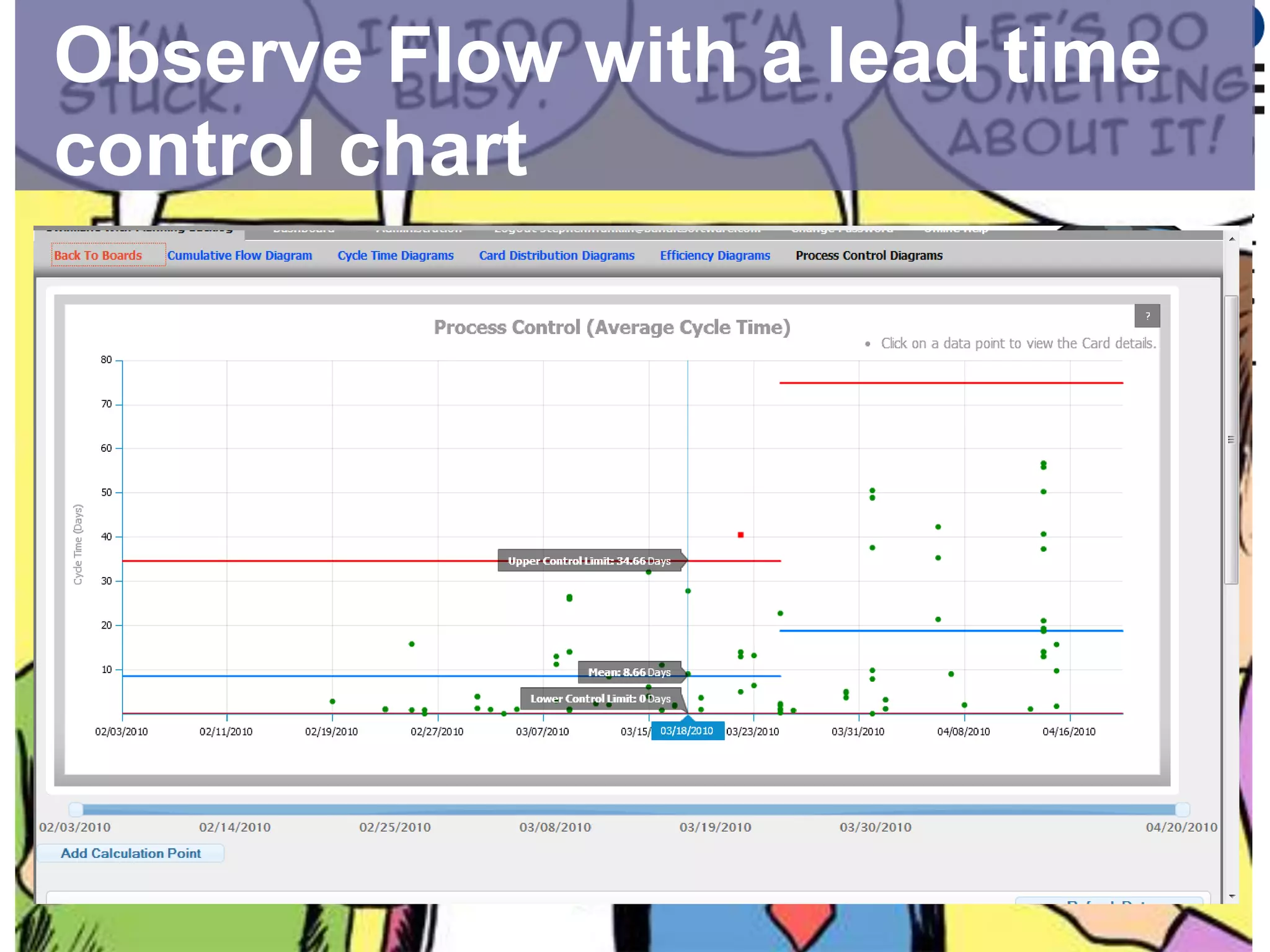

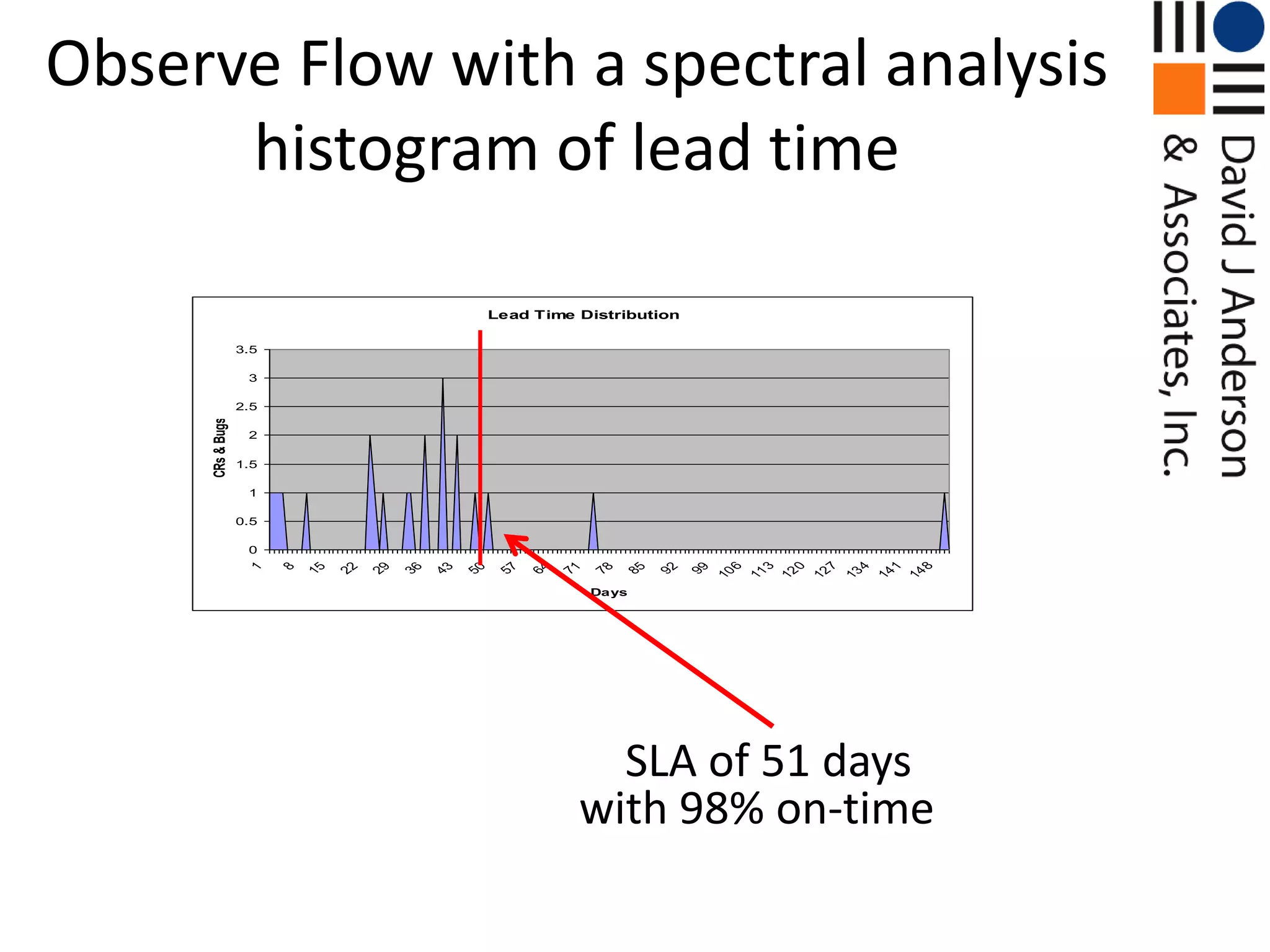

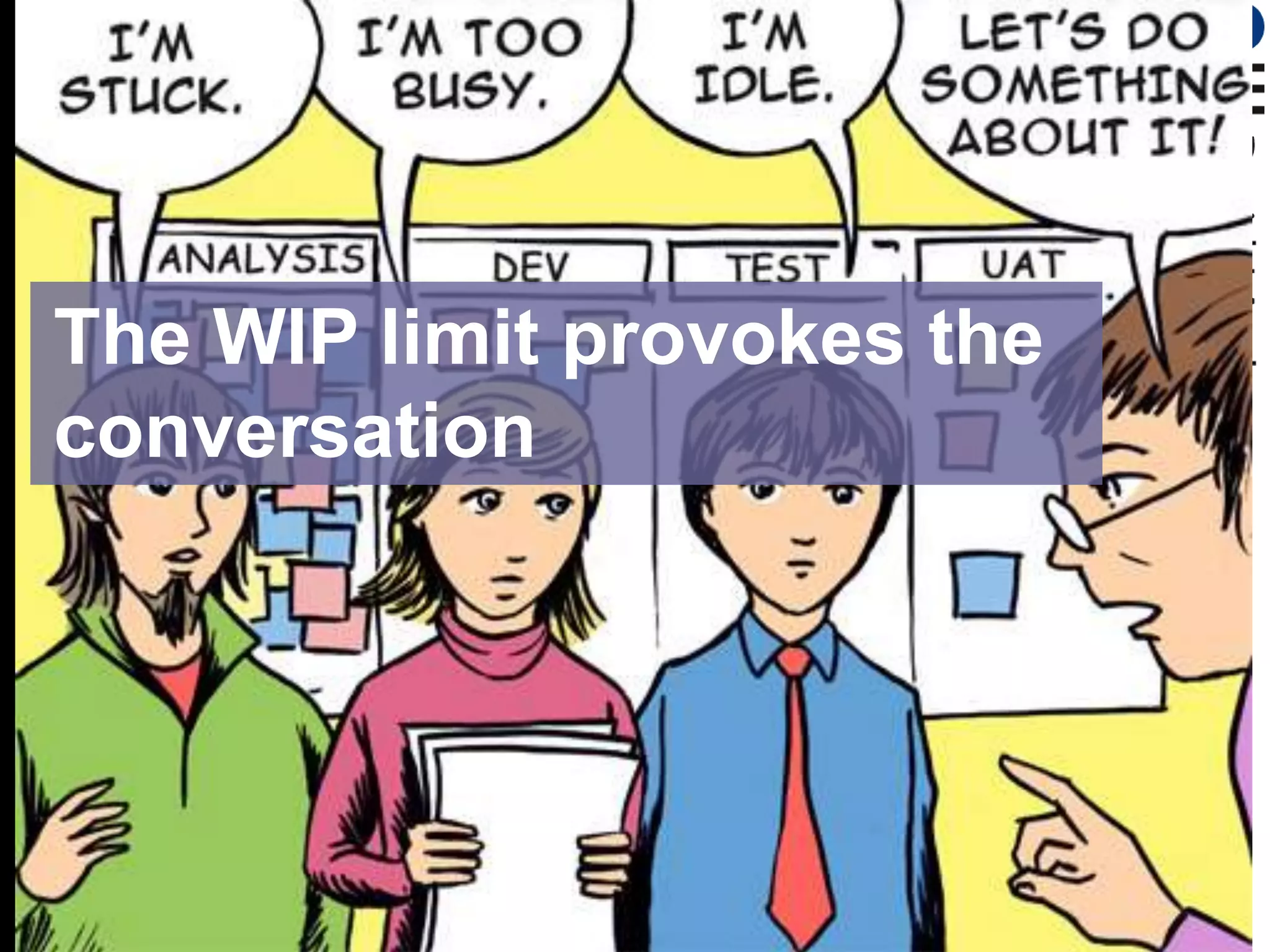

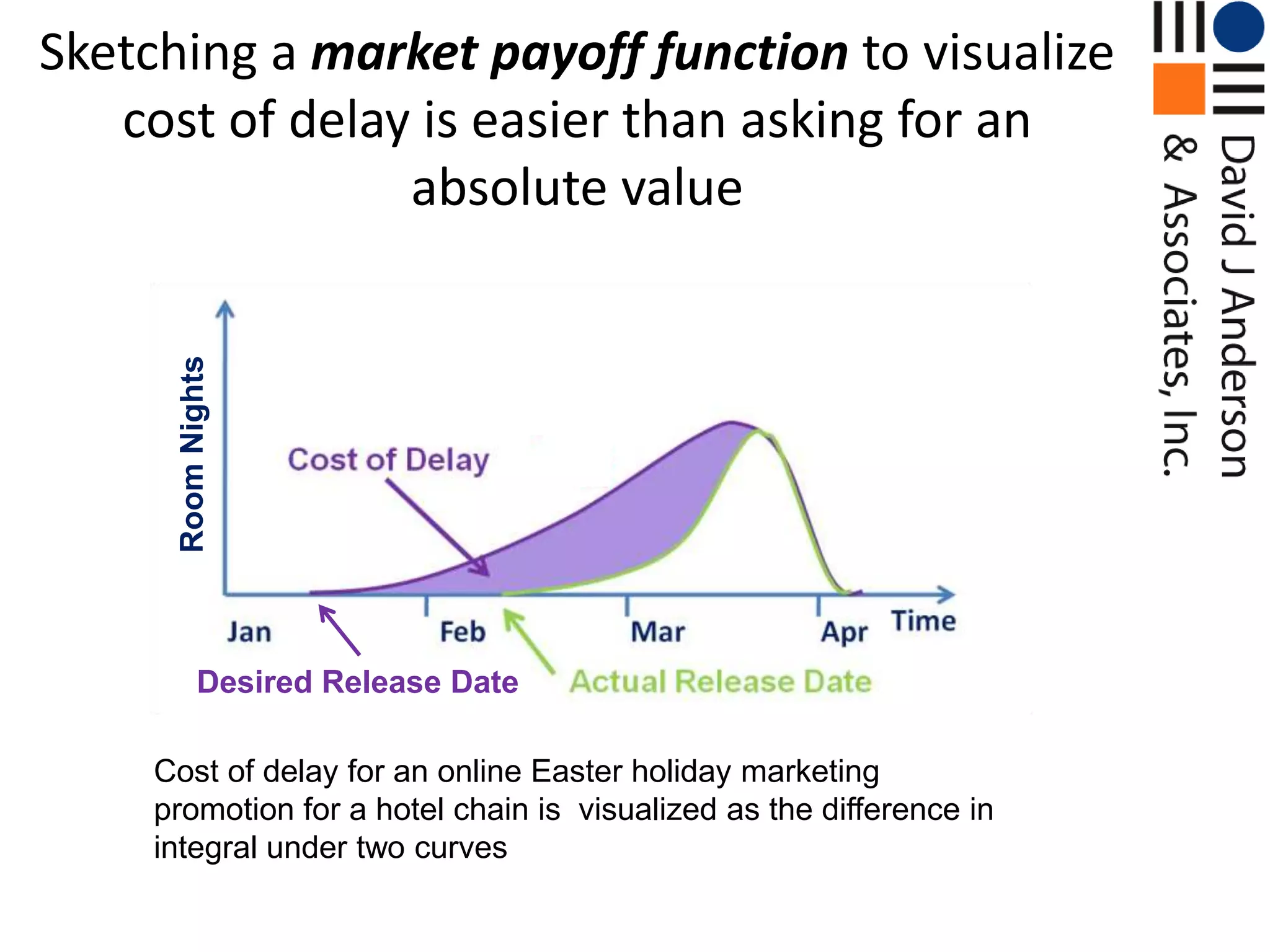

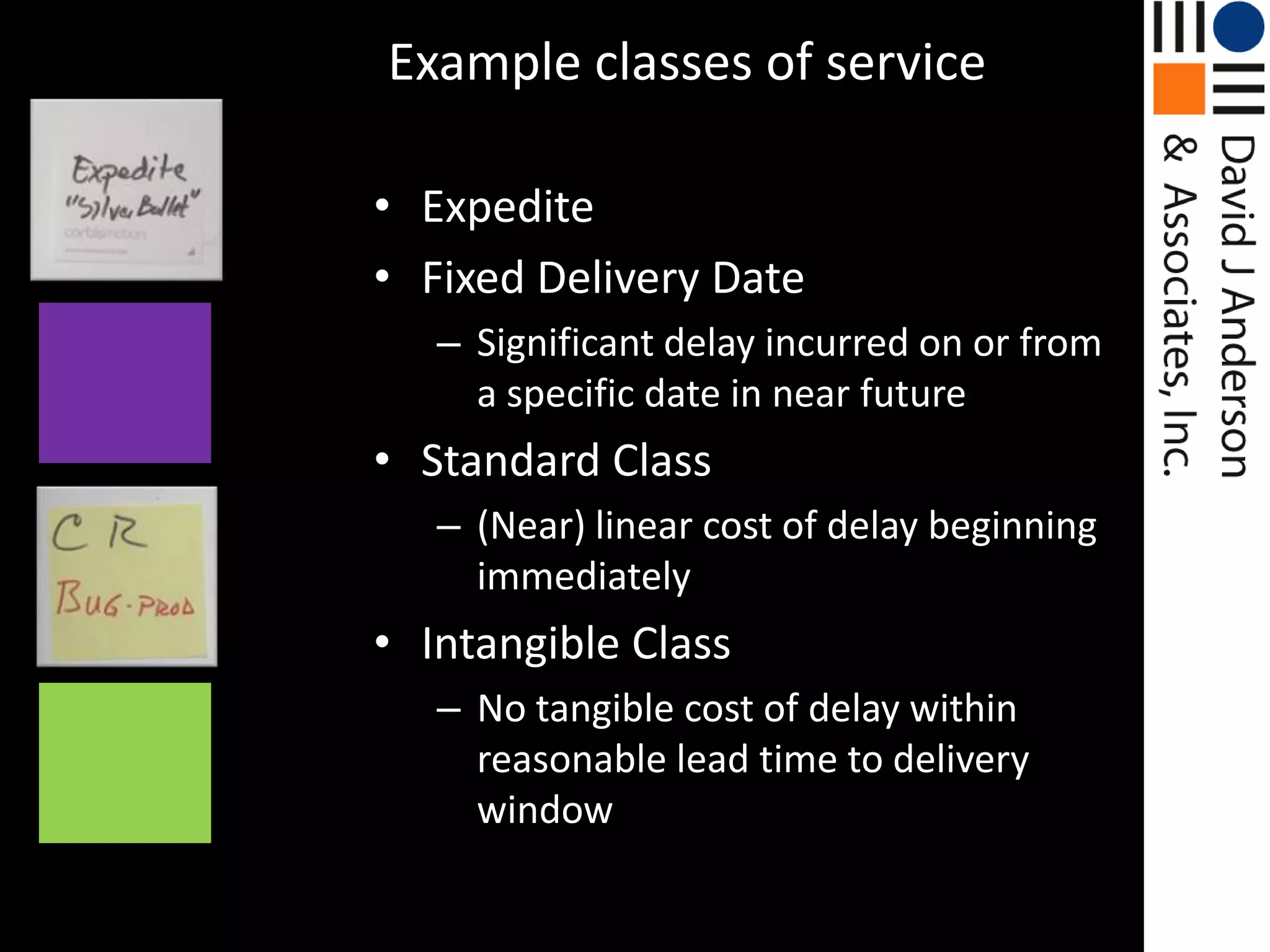

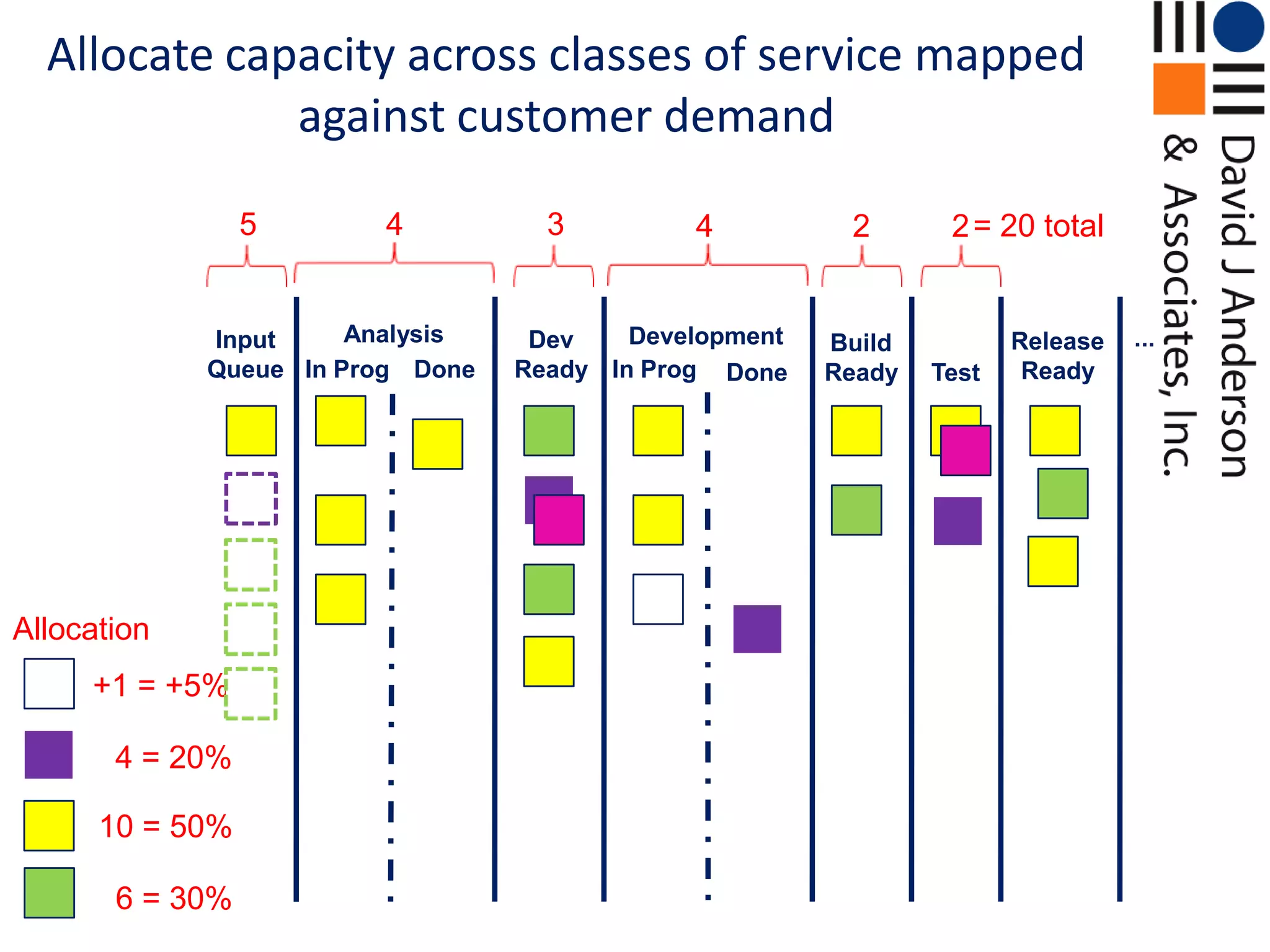

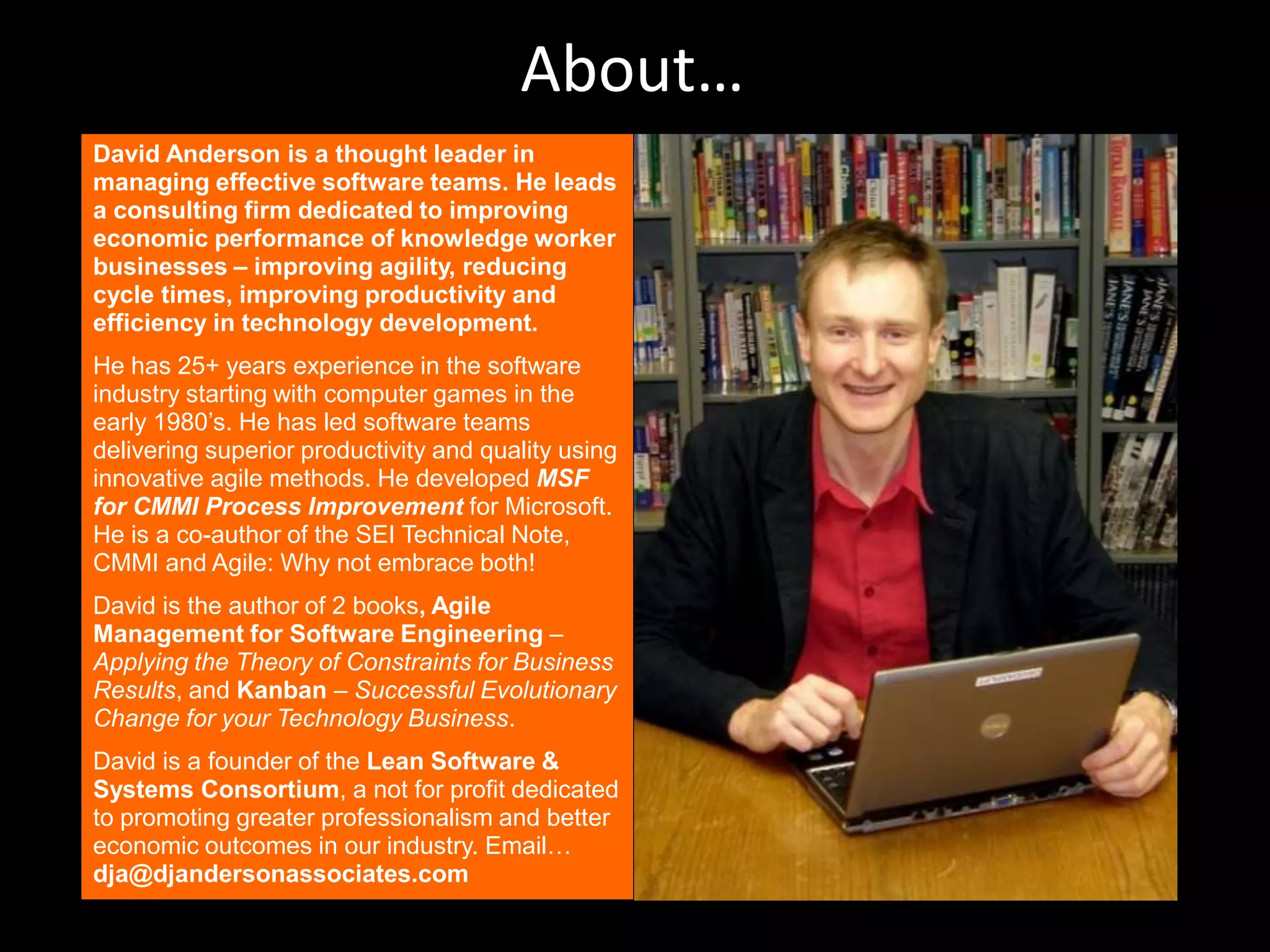

The document discusses the Kanban method as a counter-intuitive approach to establishing a lean organization, highlighting its enabling role in fostering a culture of continuous improvement. Key principles of Kanban include starting with current processes, limiting work-in-progress, and promoting evolutionary change, which facilitate the emergence of lean practices in various organizations. The author argues that successful implementation of Kanban requires leadership, transparency, and a focus on collaborative improvement, which ultimately leads to enhanced economic and sociological outcomes.