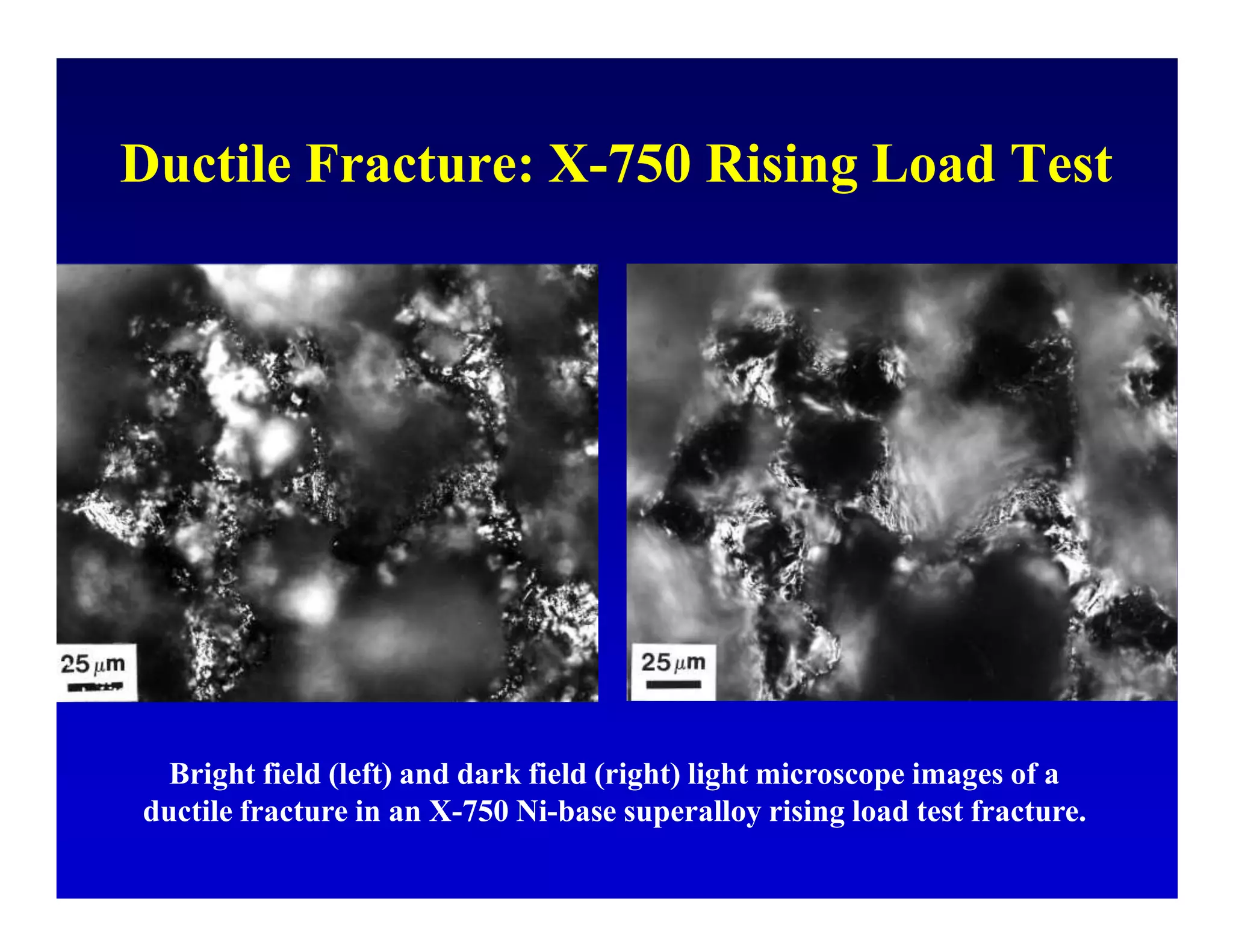

This document discusses failure analysis of fractured components. It begins by providing context on how failures of ships and bridges during WWII led to the development of fractography and fracture mechanics. It then lists common reasons for conducting a failure analysis, such as determining the cause of failure and preventing future issues. Various failure modes like ductile, brittle, fatigue and stress corrosion cracking are described. The document provides guidance on examining fractured components and outlines microscopic features that can be observed. Examples of different failure modes in materials are shown through micrographs. Overall, the document serves as a guide for understanding and investigating component failures through fractography.