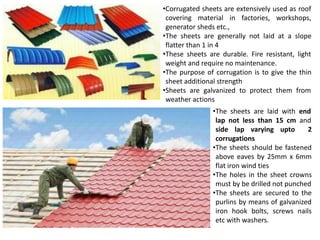

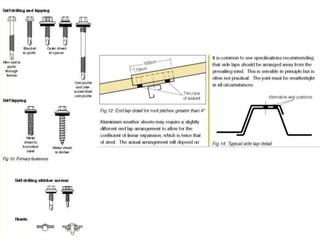

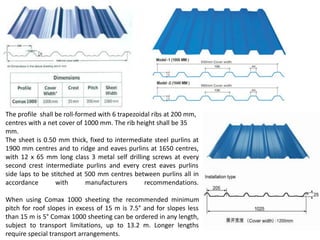

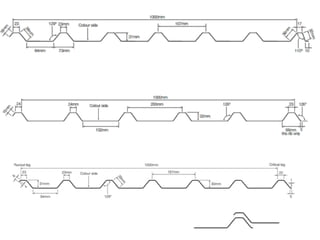

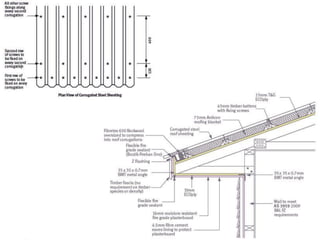

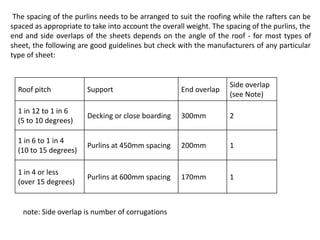

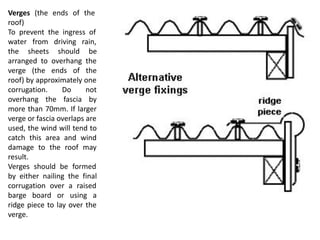

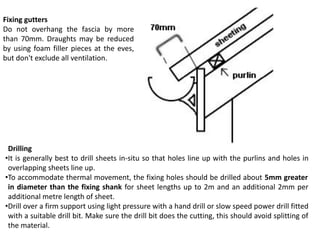

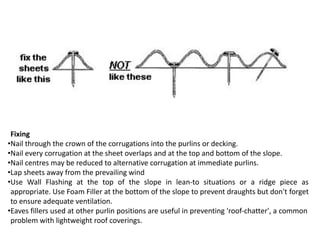

The document outlines the specifications and installation guidelines for corrugated sheet roofing, emphasizing their durability, fire resistance, and maintenance-free qualities. It details installation techniques, recommended overlaps, fastening methods, and considerations for purlin spacing based on roof pitch. Additional instructions for drilling, fixing, and preventing draughts are also provided to ensure proper assembly and performance of the roofing system.