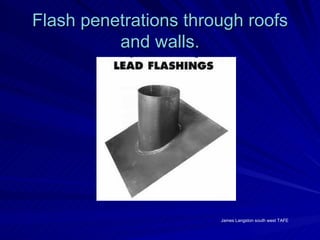

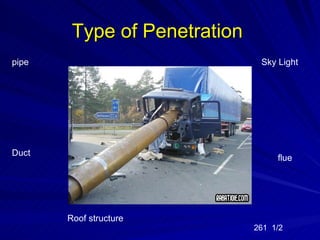

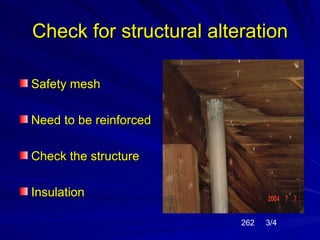

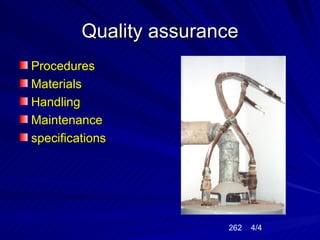

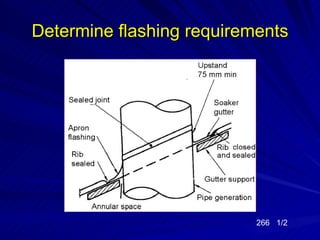

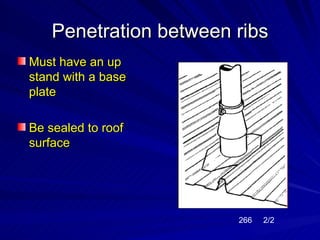

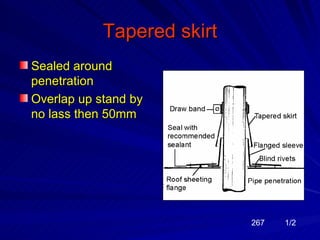

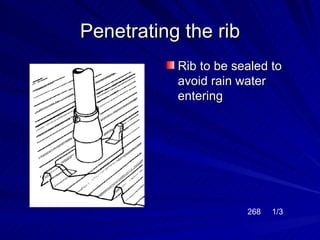

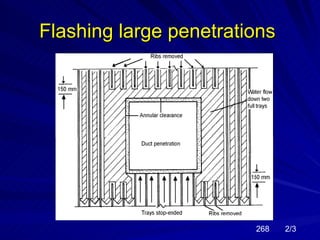

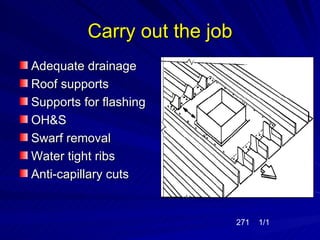

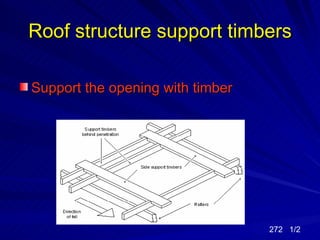

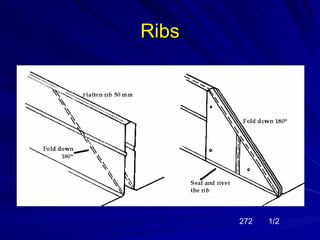

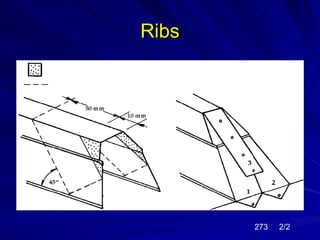

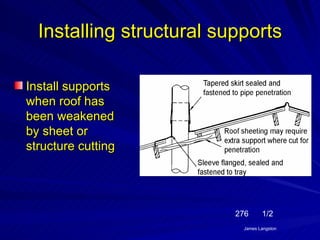

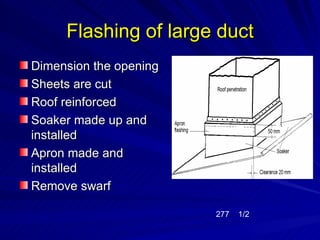

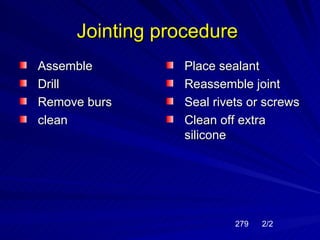

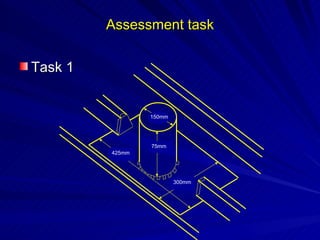

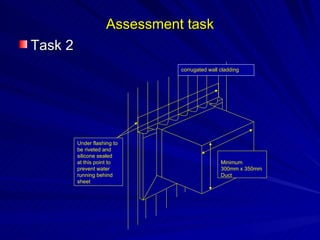

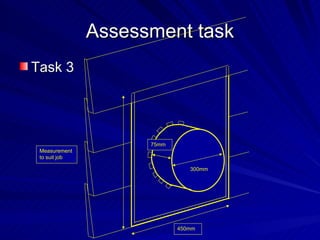

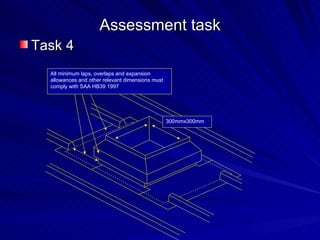

The document discusses flashings for roof and wall penetrations. It describes different types of flashings including custom made flashings made of materials like steel, zinc, lead, copper, aluminum or stainless steel. Prefabricated flashings are also discussed. The document outlines the process for installing flashings which includes establishing the type of penetration, material to be used, conducting inspections, checking plans and structures, using proper safety equipment and tools, and ensuring the installation is water tight. Key steps like supporting openings, joining materials, and using sealants are also covered. Assessment tasks with diagrams are provided at the end to test understanding.