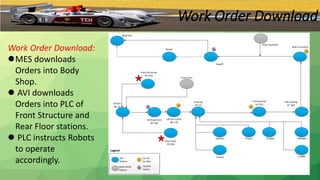

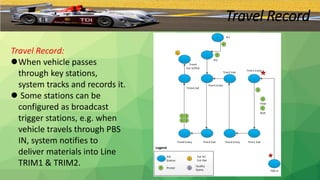

Vehicle manufacturing automation uses Automatic Vehicle Identification (AVI) to identify vehicles via RFID or labels and schedule manufacturing routes. AVI integrates with conveyors via programmable logic controllers (PLCs) and interacts with ERP/WMS systems as a core MES module. AVI functions include work order download, vehicle identification, travel record, sequence management, and quality gates to route vehicles through production and repair. AVI can use RFID tags or labels for identification and communicates between readers and an AVI server via different network configurations.