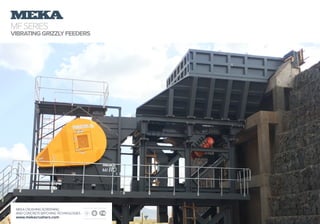

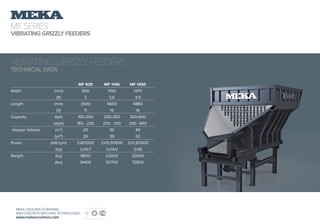

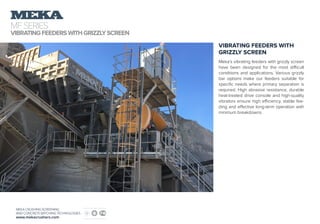

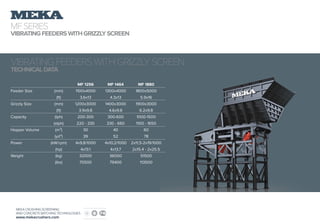

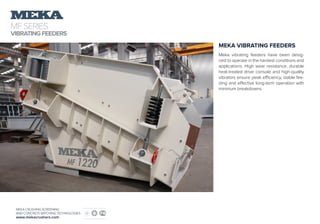

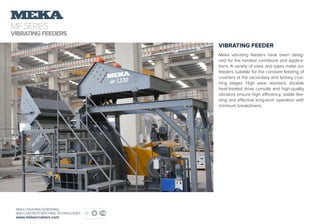

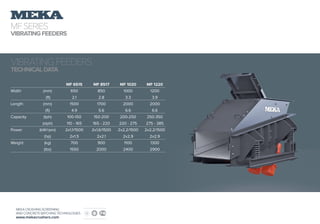

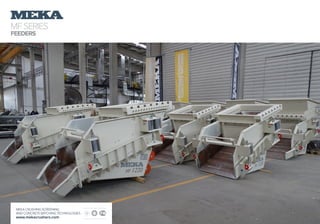

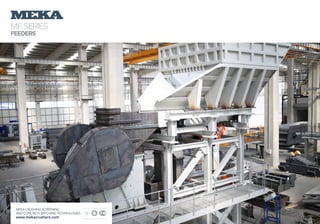

Meka offers a range of crushing, screening, and concrete batching technologies, including various types of feeders designed for optimal material flow and increased efficiency in processing. Their MF series feeders, featuring vibrating models, are engineered for durability and effectiveness in harsh conditions, supporting the feeding of crushers at different stages. With over 2,000 installations globally, Meka is a reputable choice among industry leaders recognized for its quality and innovation.