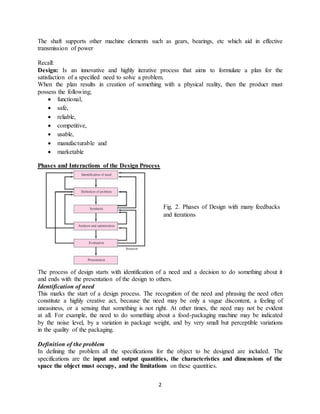

This document provides an overview of the design process for mechanical power transmission systems. It discusses the key phases of design including problem identification, problem definition, synthesis, analysis and optimization, evaluation, and presentation. It emphasizes that design is an iterative process, with the phases interacting and feeding back on each other. As an example, it discusses how the design of system components like gears, bearings and shafts requires moving back and forth between the component designs and the overall system specifications. The goal is to refine estimates to arrive at a final optimized design that satisfies requirements for both individual parts and the full system.