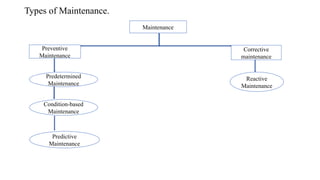

The document discusses the importance and types of maintenance, focusing on preventive maintenance to ensure efficient operation and extend equipment lifespan. It highlights the benefits of a maintenance schedule, including cost savings, improved safety, and compliance with regulations. Additionally, it addresses the costs associated with both performing and neglecting maintenance, emphasizing its role in enhancing profitability for businesses.