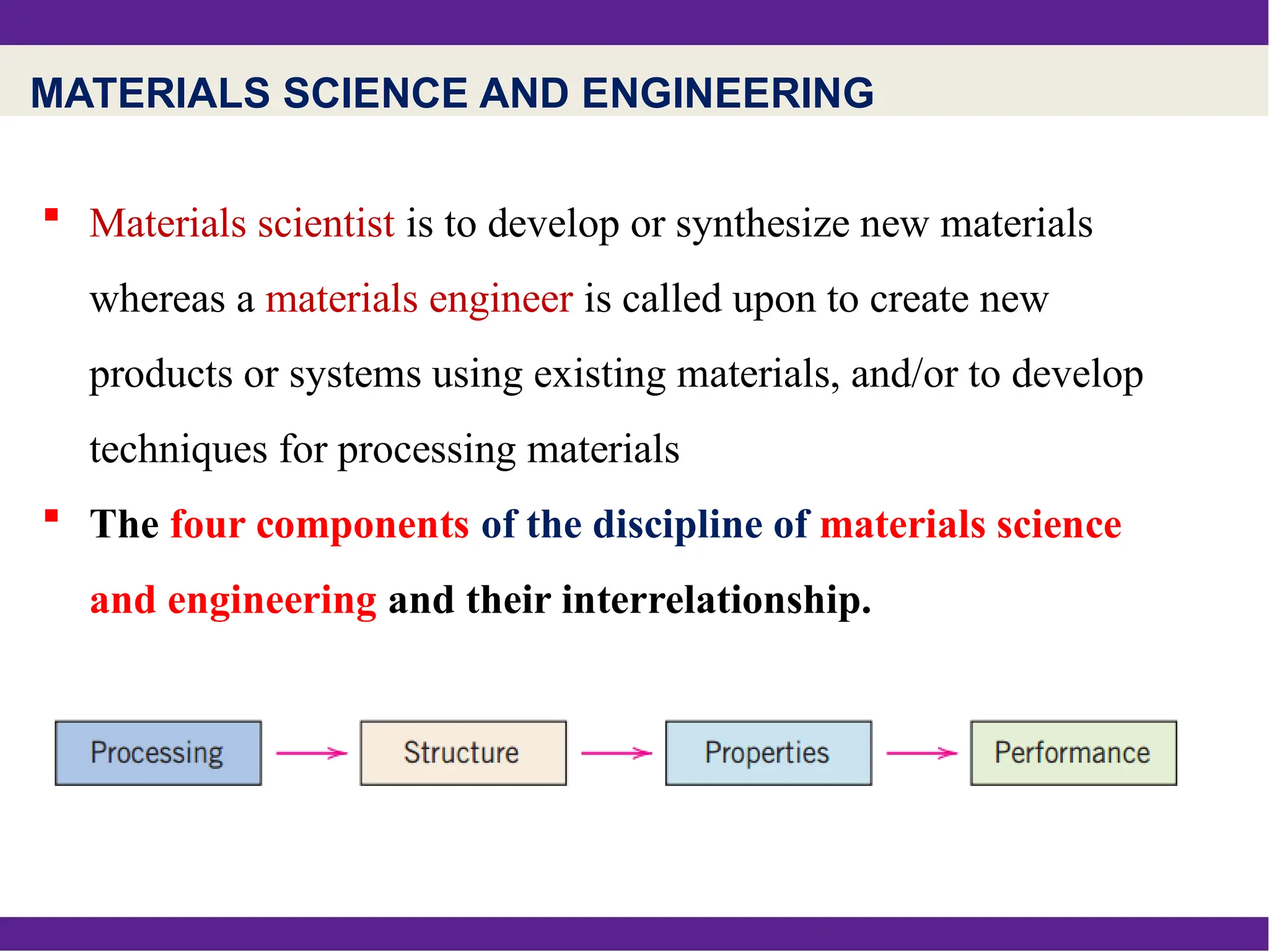

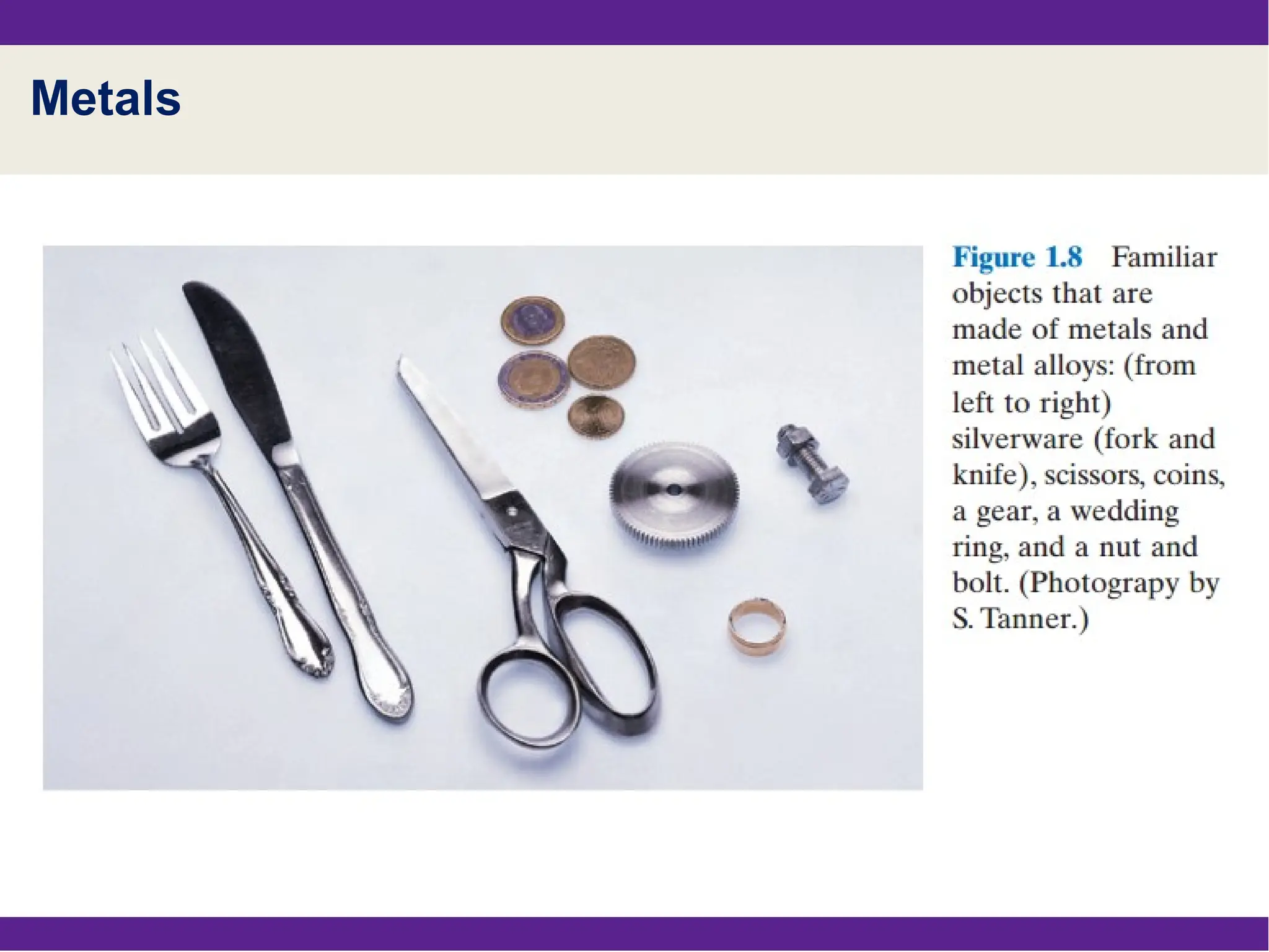

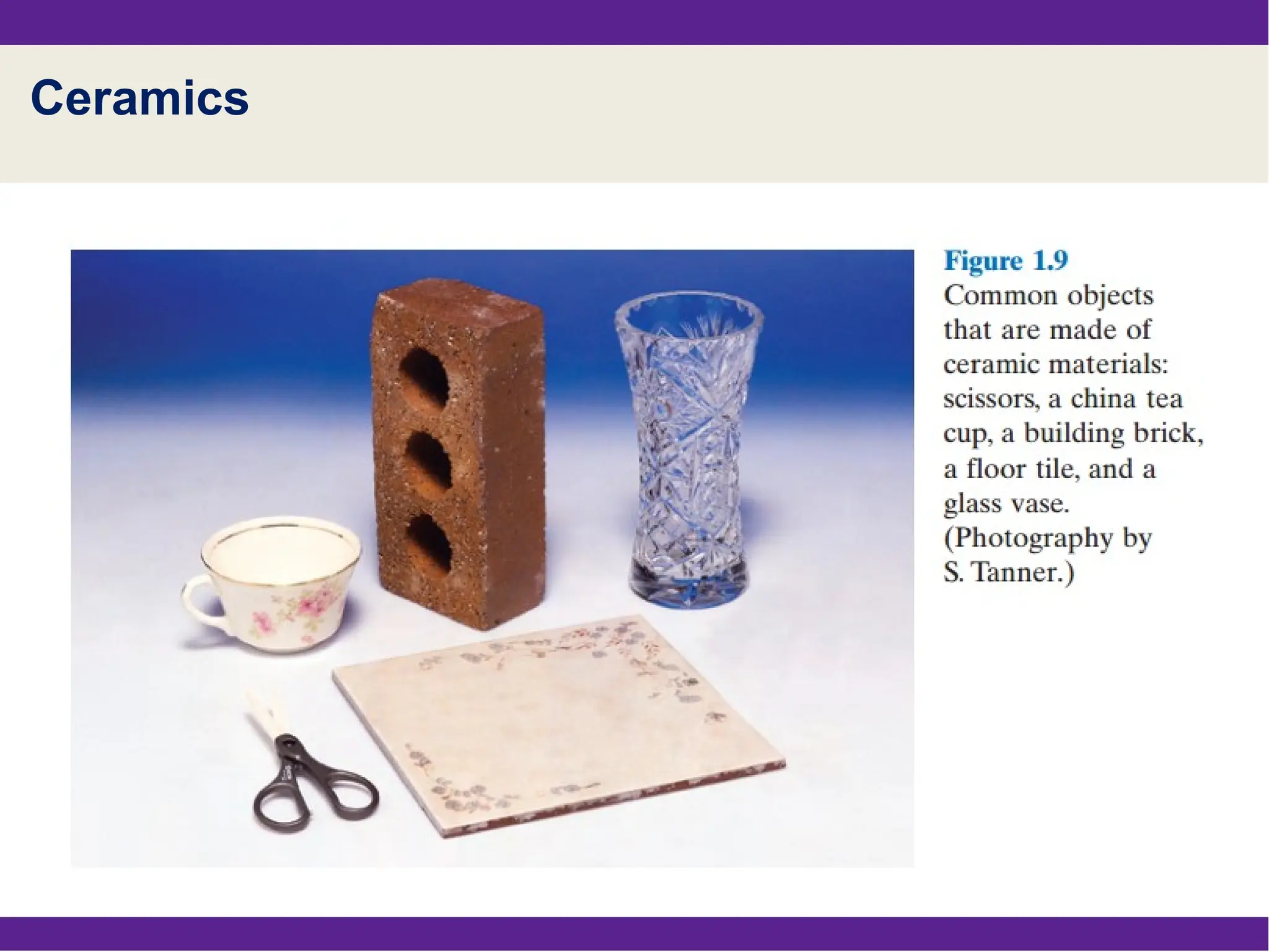

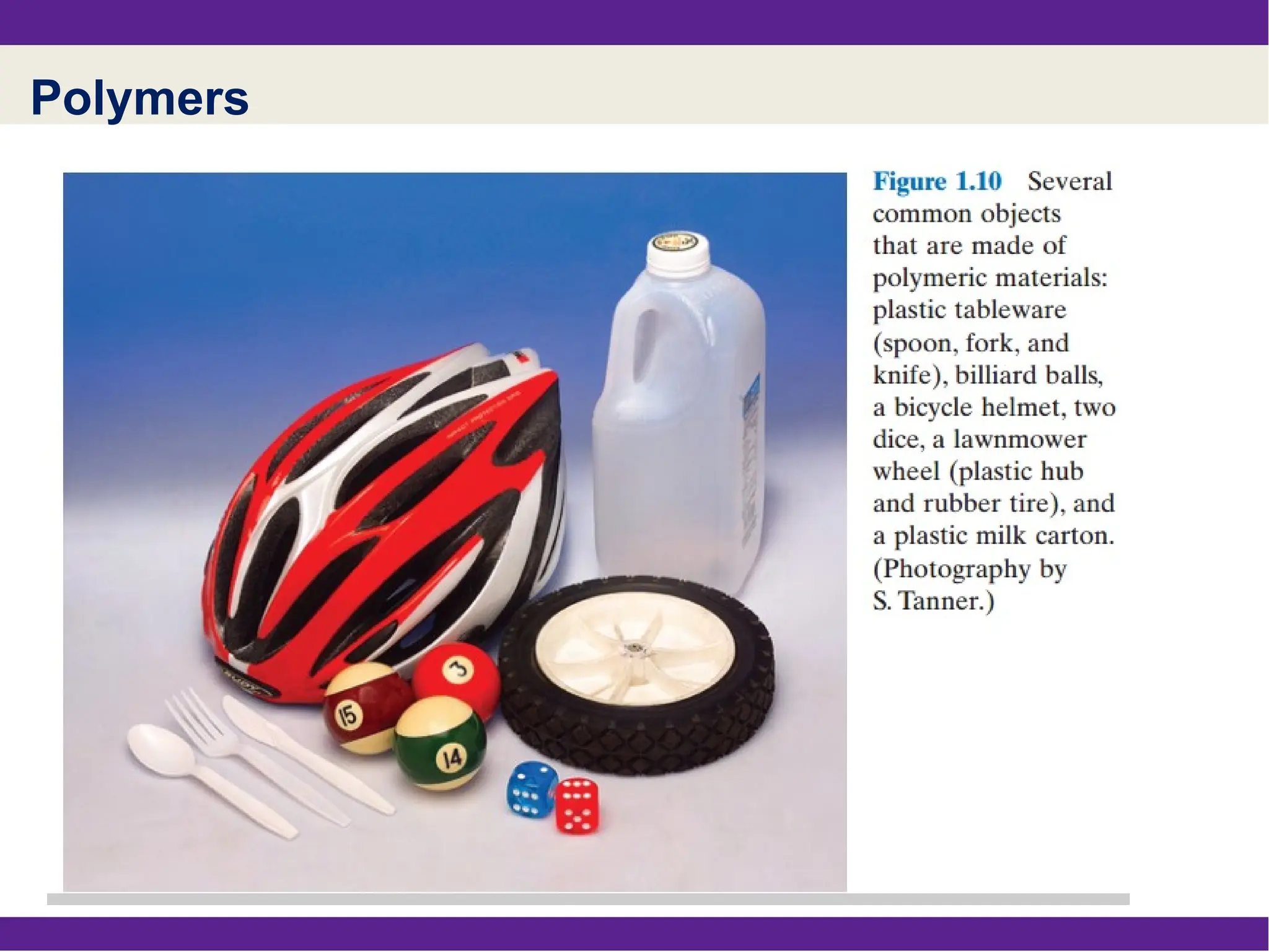

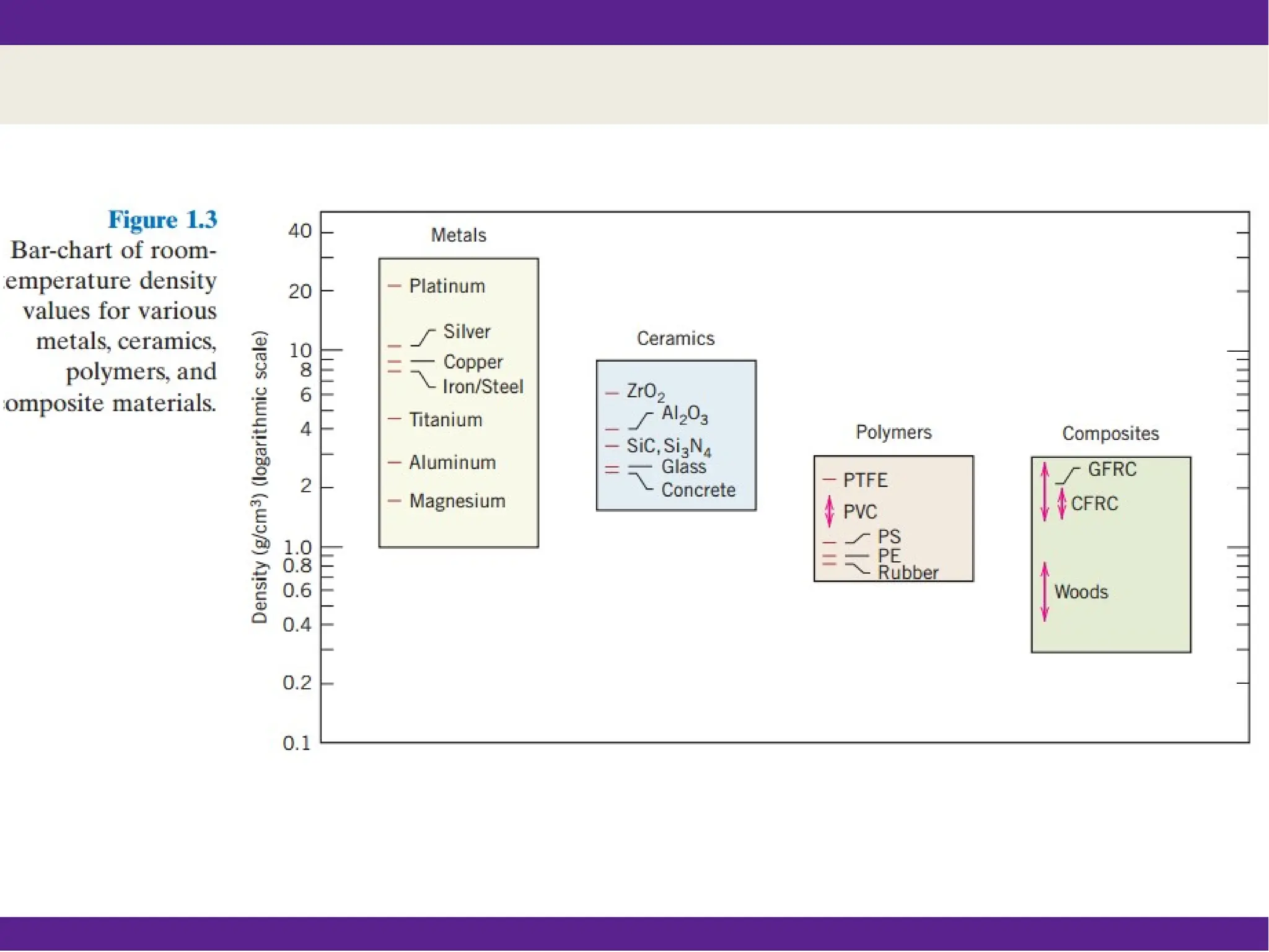

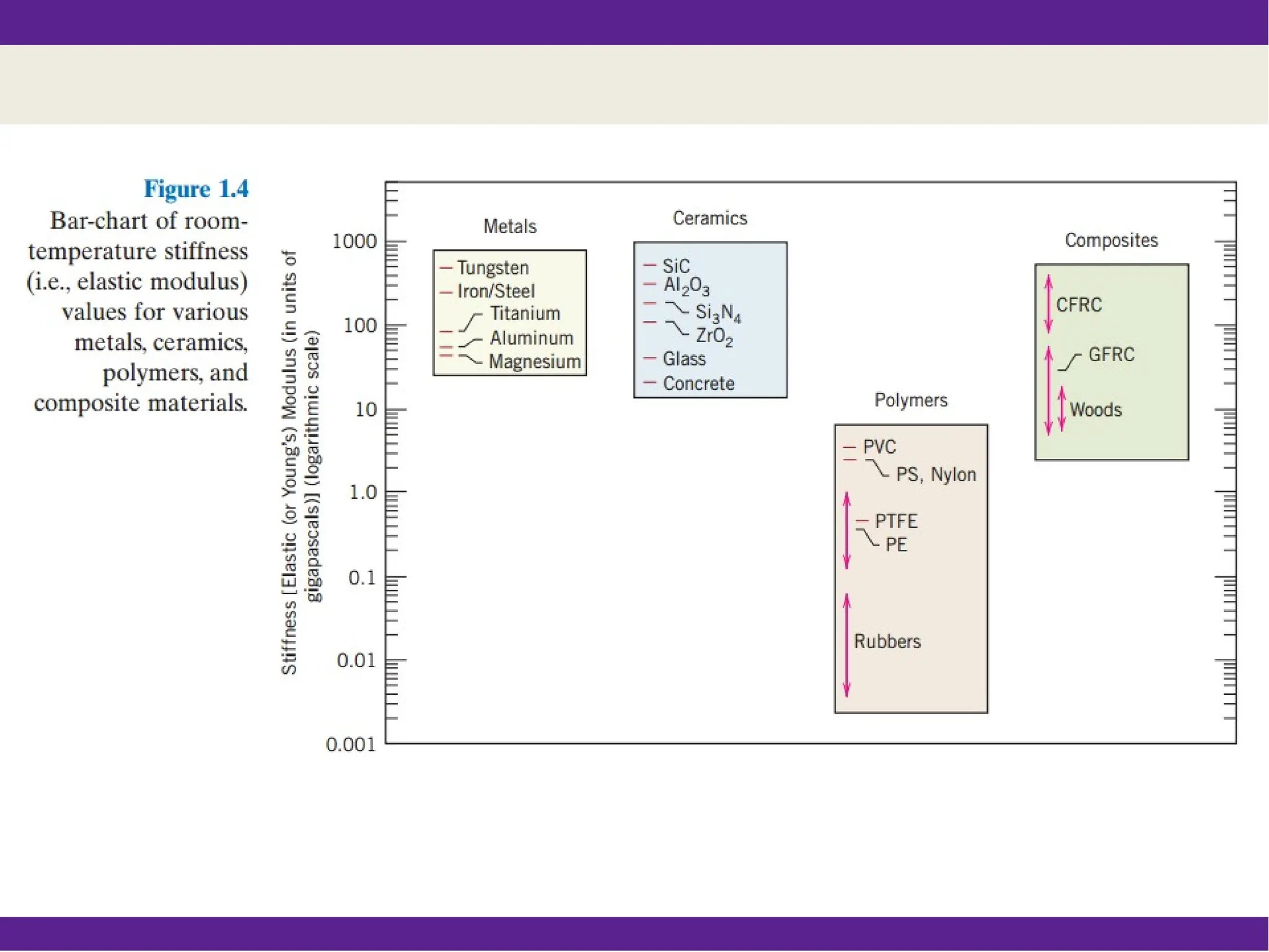

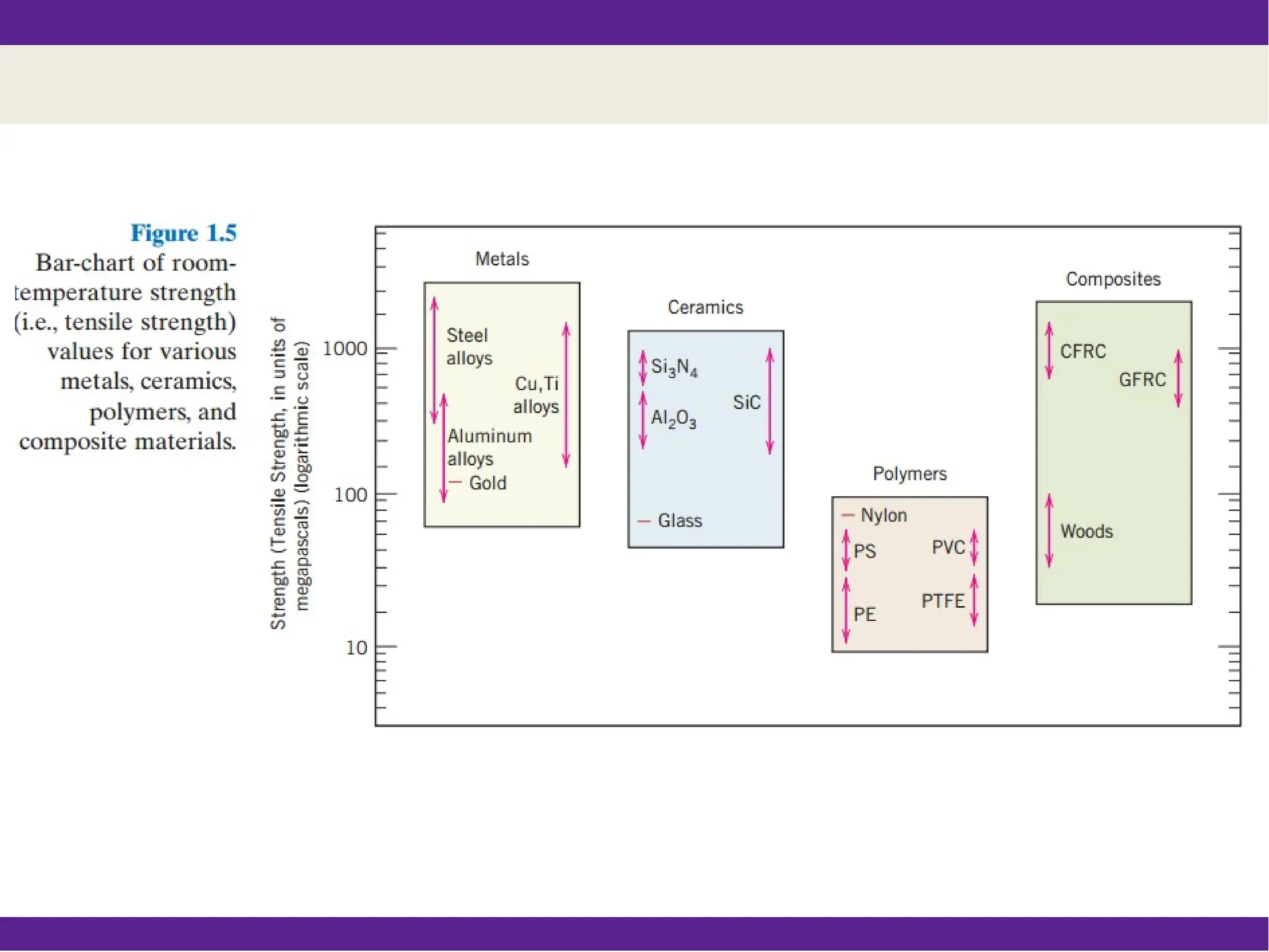

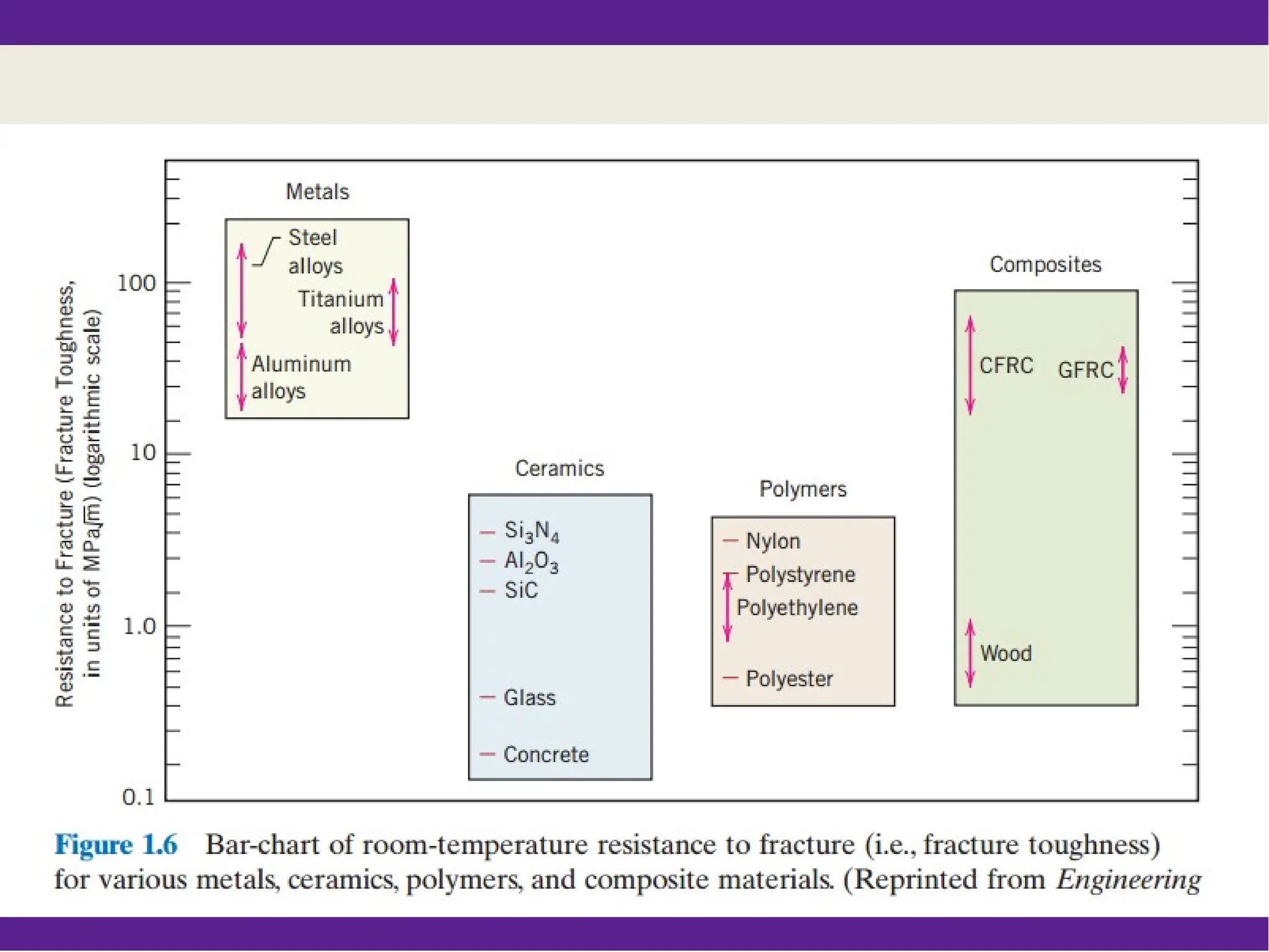

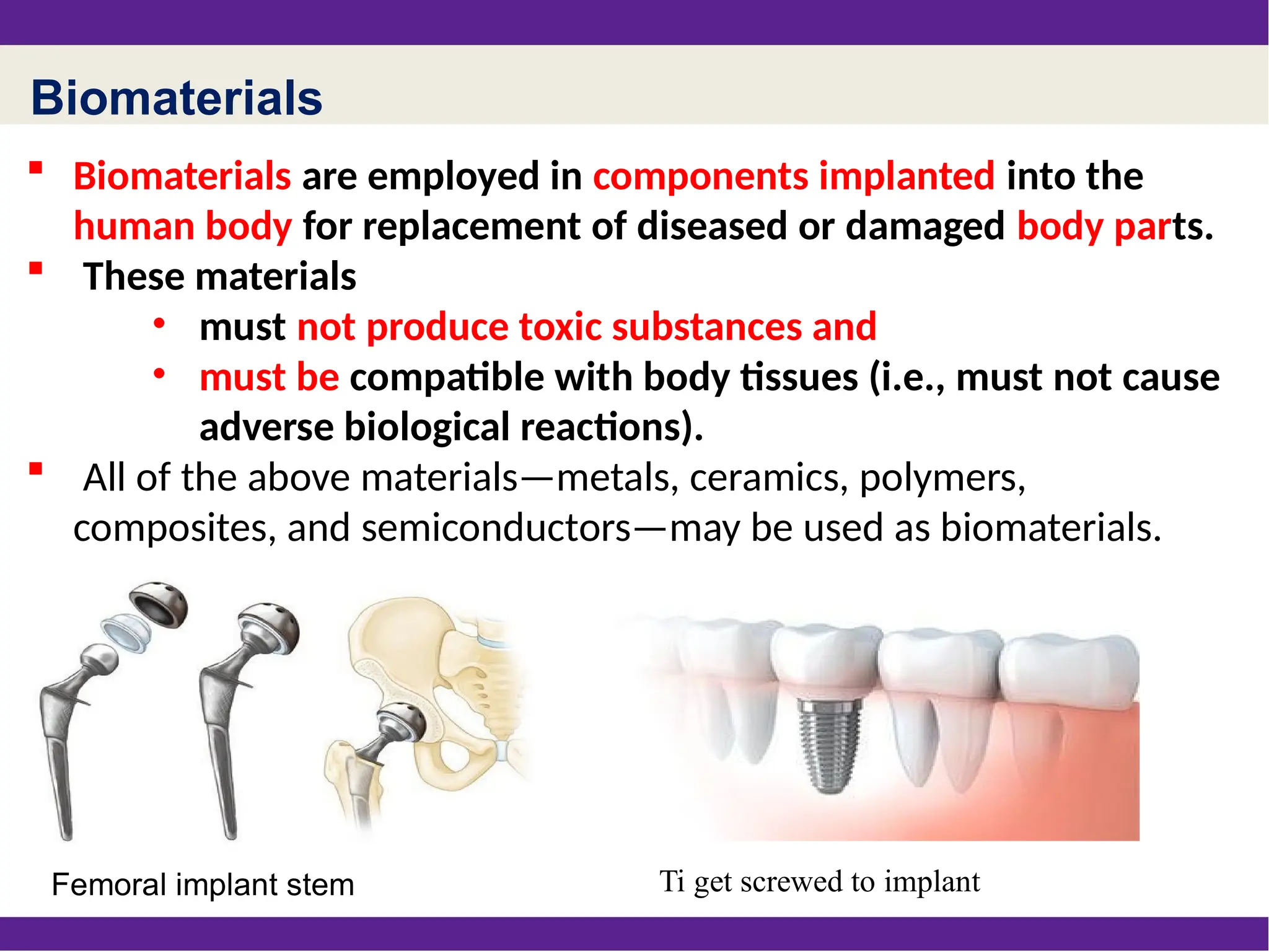

The document provides an overview of materials science and engineering, highlighting the classification of materials into metals, ceramics, polymers, and composites, as well as advanced materials like semiconductors and biomaterials. It emphasizes the relationship between a material's structure, properties, and performance, alongside the importance of selecting appropriate materials for engineering applications based on service conditions, deterioration, and economics. Additionally, it introduces 'smart' materials and nanoengineered materials as cutting-edge developments in the field.