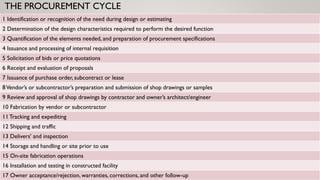

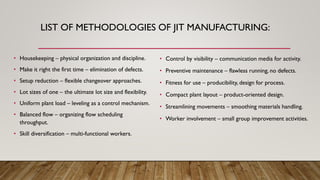

The document outlines procurement in construction, detailing processes for acquiring necessary goods, services, and contracts throughout all phases of a project. It emphasizes the importance of ethical standards, effective tracking, and the integration of procurement with project management systems. Additionally, it discusses methodologies such as just-in-time and various cost considerations related to procurement.