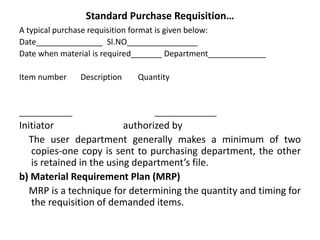

Materials management is the process of planning, obtaining, storing, and distributing materials needed for production in a timely and cost-effective manner. The key functions include planning and forecasting demand, purchasing materials, inventory control, and ensuring smooth material flow. The document provides an overview of materials management, its importance and scope. It discusses how materials management interacts and coordinates with other functions like operations, finance, marketing, and human resources. The summary also touches on different techniques for demand forecasting and purchasing policies and procedures.