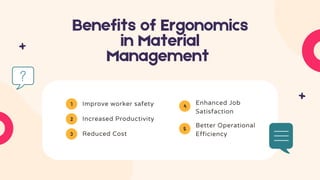

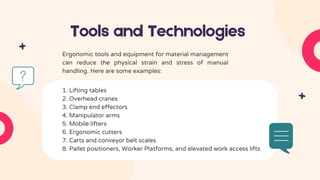

Materials management is a vital component of supply chain management focused on ensuring the right materials are available at the right time and cost while managing inventory and suppliers. Key challenges include demand forecasting, supplier reliability, and cost management, while best practices emphasize accurate forecasting, supplier relationships, and technology use. Ergonomics plays a significant role in materials management by optimizing worker safety and efficiency through proper tool design and workspace arrangement.