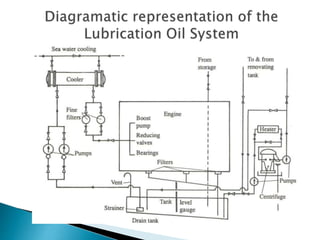

The document discusses various aspects of fuel oil systems, including the importance of ignition quality denoted by cetane number, which affects engine performance. It outlines methods to improve ignition quality, such as adjusting engine settings and using pilot injection systems to ensure smooth combustion. Additionally, the document details the lubrication oil system, emphasizing the need for proper maintenance, oil analysis, and cooling systems to prevent contamination and overheating.