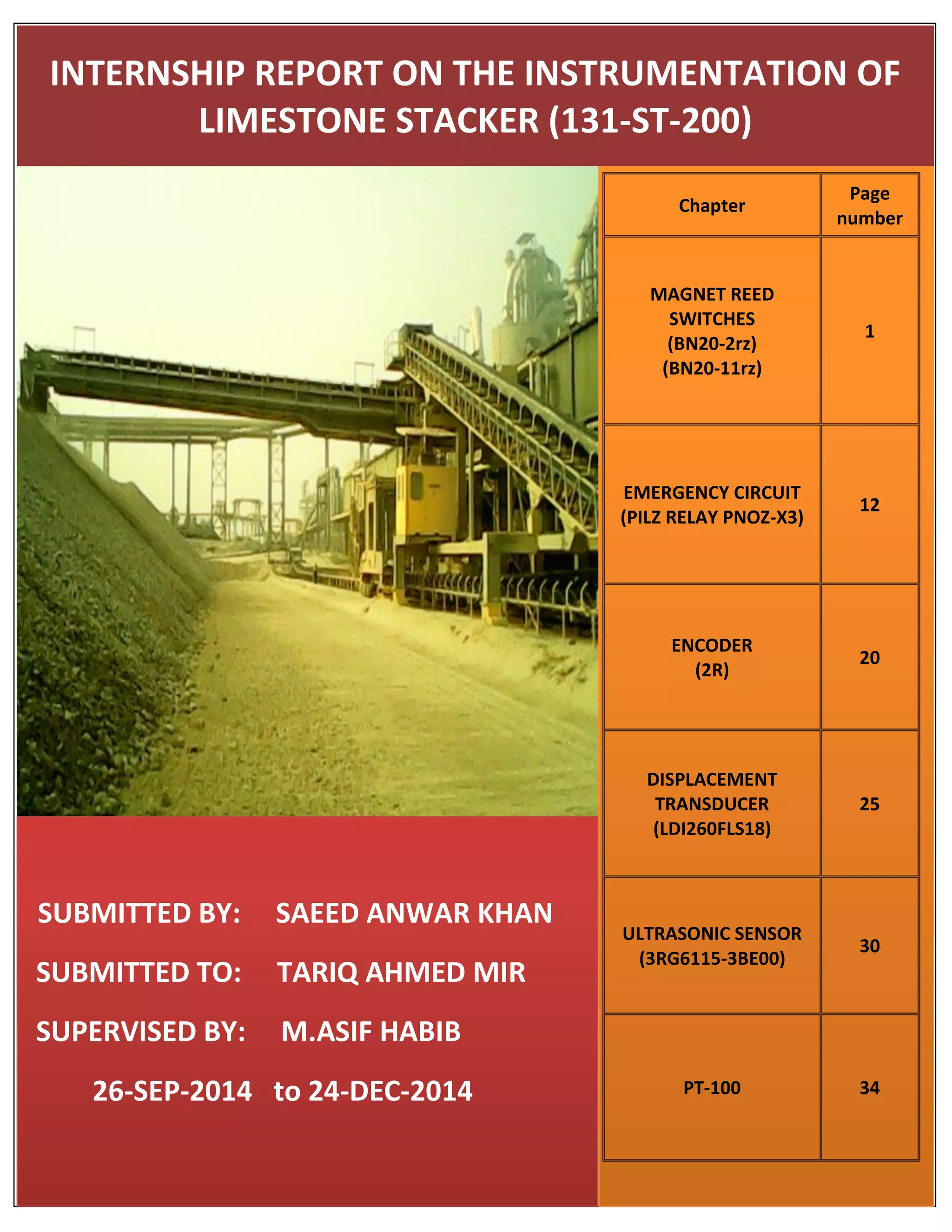

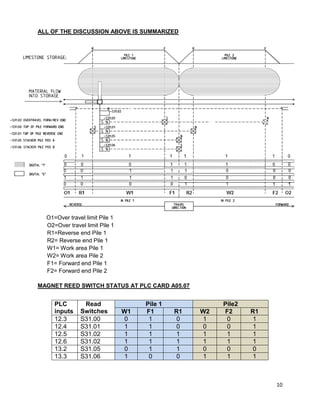

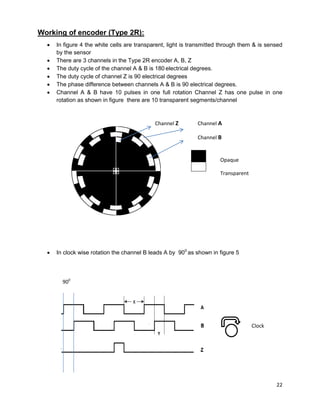

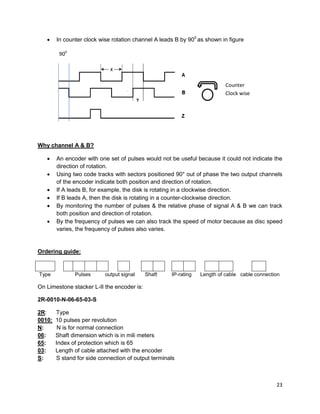

The document discusses magnet reed switches and encoders used on a limestone stacker. It provides details on how reed switches work using magnets and how they are used to sense position. It also discusses the incremental encoder used, which is a 2R encoder that outputs pulses on channels A, B, and Z to detect motion and position.

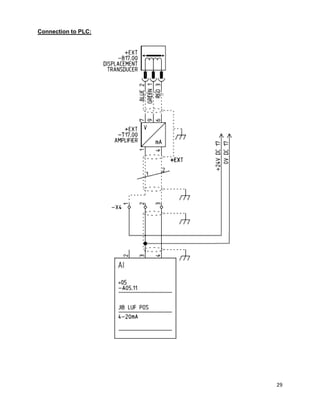

![28

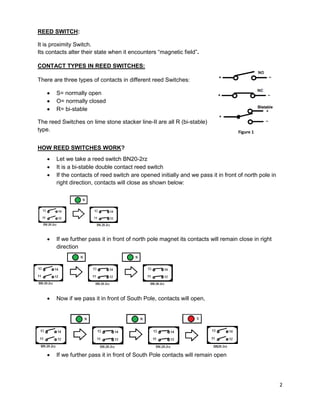

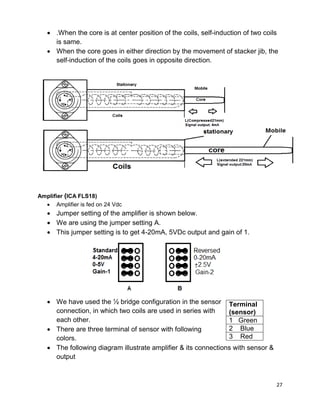

Output current versus position of transducer (mm) & Jib position (%):

Position

[mm]

Jib Position

[%]

Output

[mA]

0 0 20.1

20 10 18.39

40 20 16.79

60 30 15.18

80 40 13.58

100 50 11.99

120 60 10.37

140 70 8.77

160 80 7.20

180 90 5.59

200 100 4.00](https://image.slidesharecdn.com/final2-160717134429/85/maple-leaf-cement-storage-area-machinery-29-320.jpg)