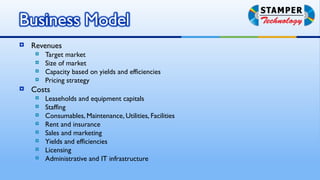

The document outlines the technical and business considerations for mastering operations in media production, detailing processes from pre-mastering to post-production. It emphasizes the importance of quality control, equipment requirements, operational efficiency, and customer service within the industry. The document also highlights the need for ongoing feedback and process optimization to correlate mastering techniques with customer expectations.