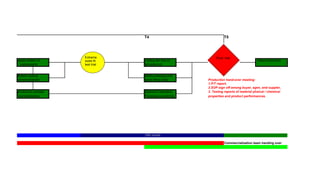

The document outlines the new product development process from concept creation through commercialization. Key steps include concept review, prototype development, fit sampling, tooling trials, production trials, and handing off to production. Milestones include design checkpoints, sample reviews, fit checks, tooling revisions, confirmation of production processes and standards, and sign off before mass production and commercialization. The process takes around 11 months from start to finish.