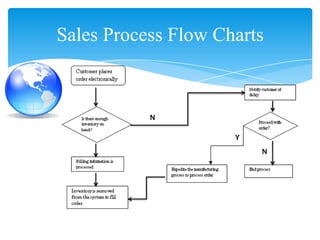

This document provides an overview of a systems development project for Riordan Manufacturing to implement an inventory and supply chain management software. It describes Riordan Manufacturing's background and current manual paper-based processes. The objectives are to identify issues with the current system and propose improvements. Key opportunities identified include decreasing labor costs and improving productivity by automating inventory tracking across raw materials receiving, manufacturing, product inventory, and sales orders. The proposed solution is to implement NetSuite software to streamline the customer ordering, inventory management, and manufacturing processes.