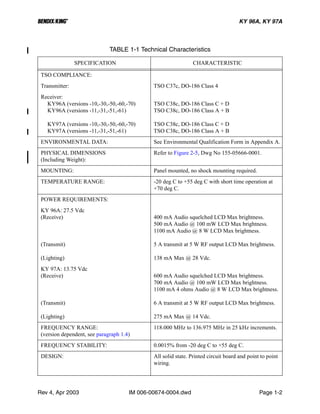

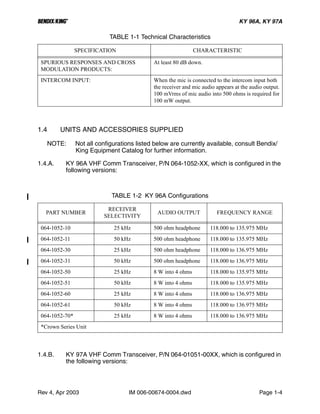

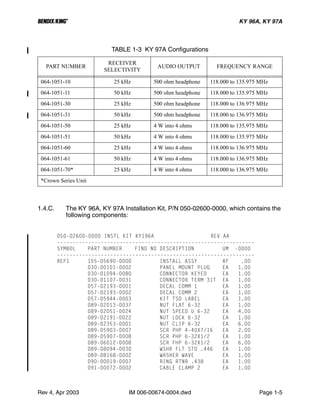

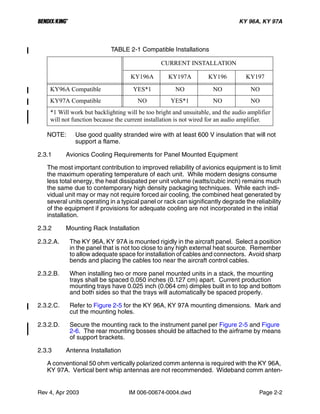

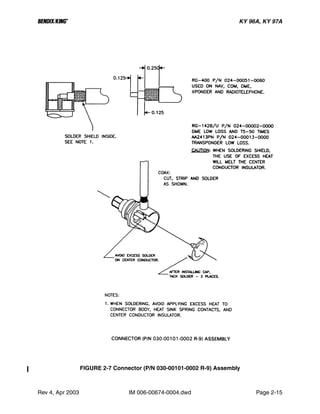

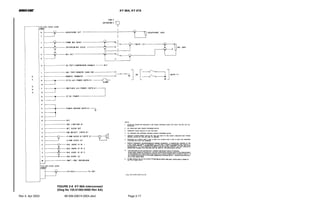

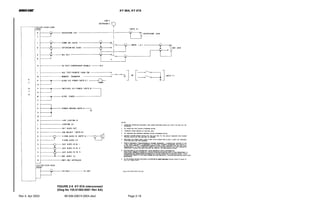

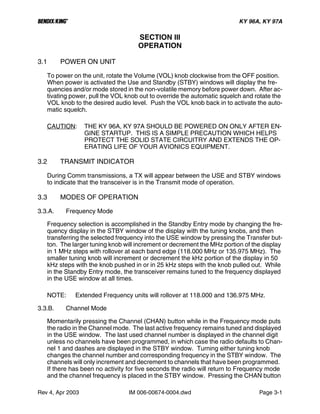

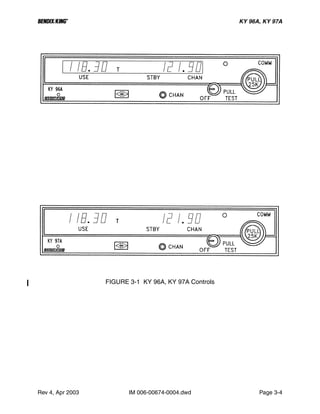

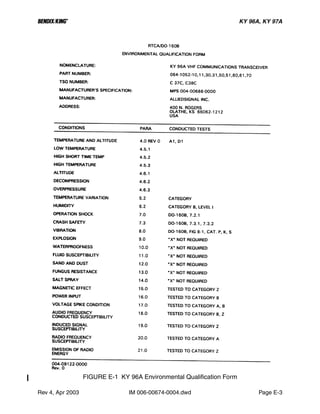

This document provides installation and operation instructions for the Bendix/King KY 96A and KY 97A VHF communication transceivers. It describes the technical specifications of the equipment including frequency range, power requirements, transmitter and receiver characteristics. It also lists the standard configurations and accessories supplied with the units.