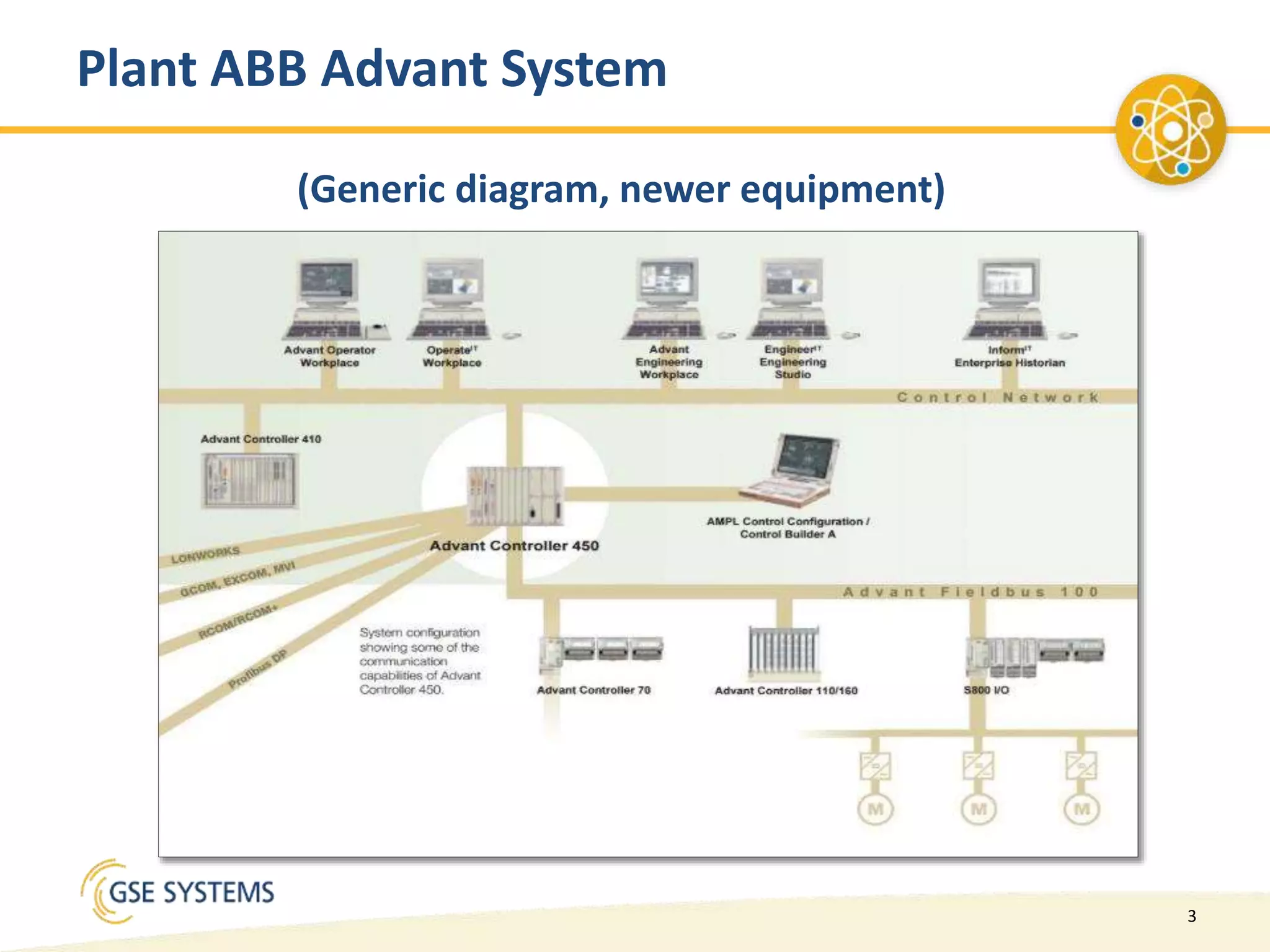

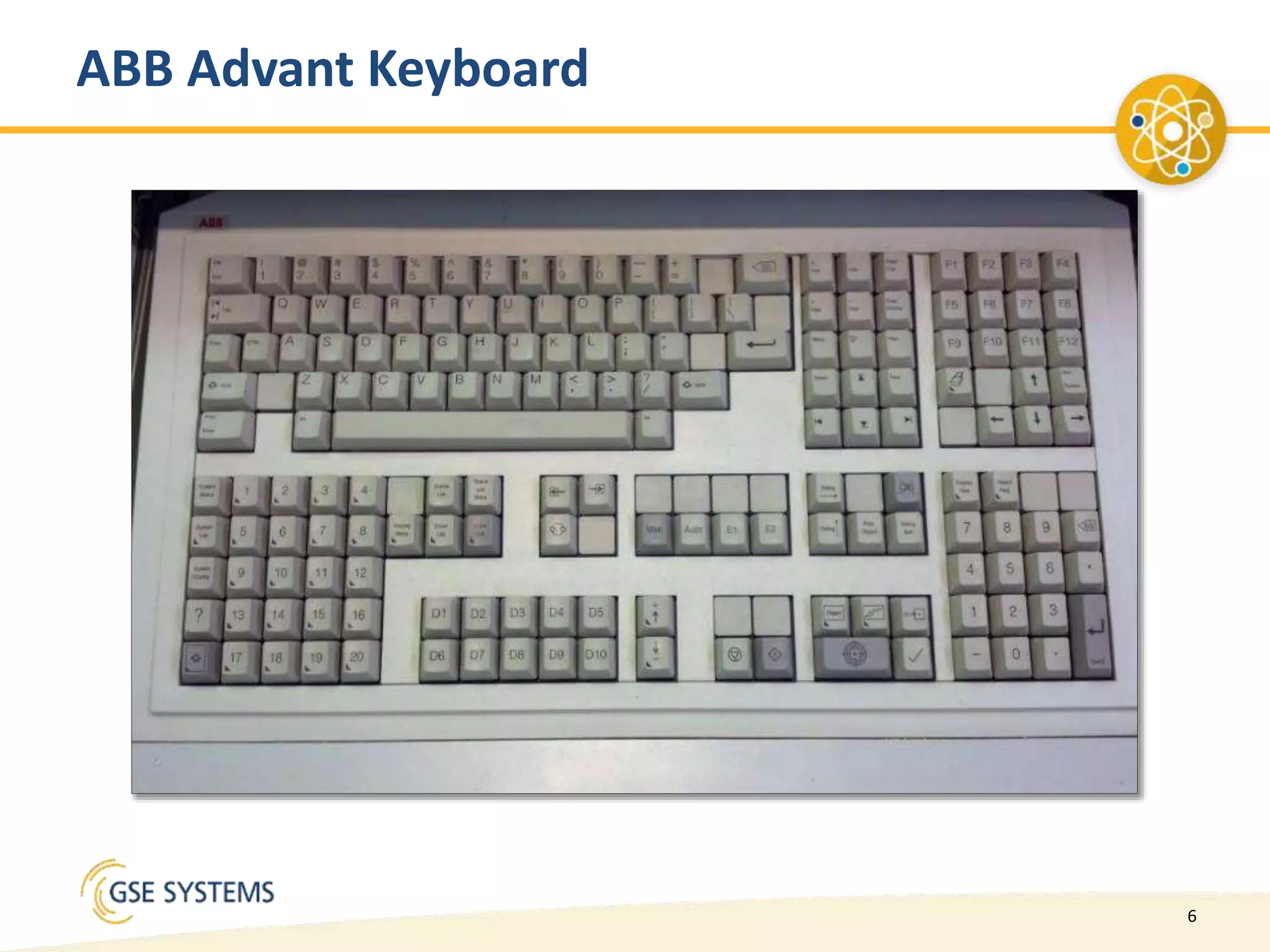

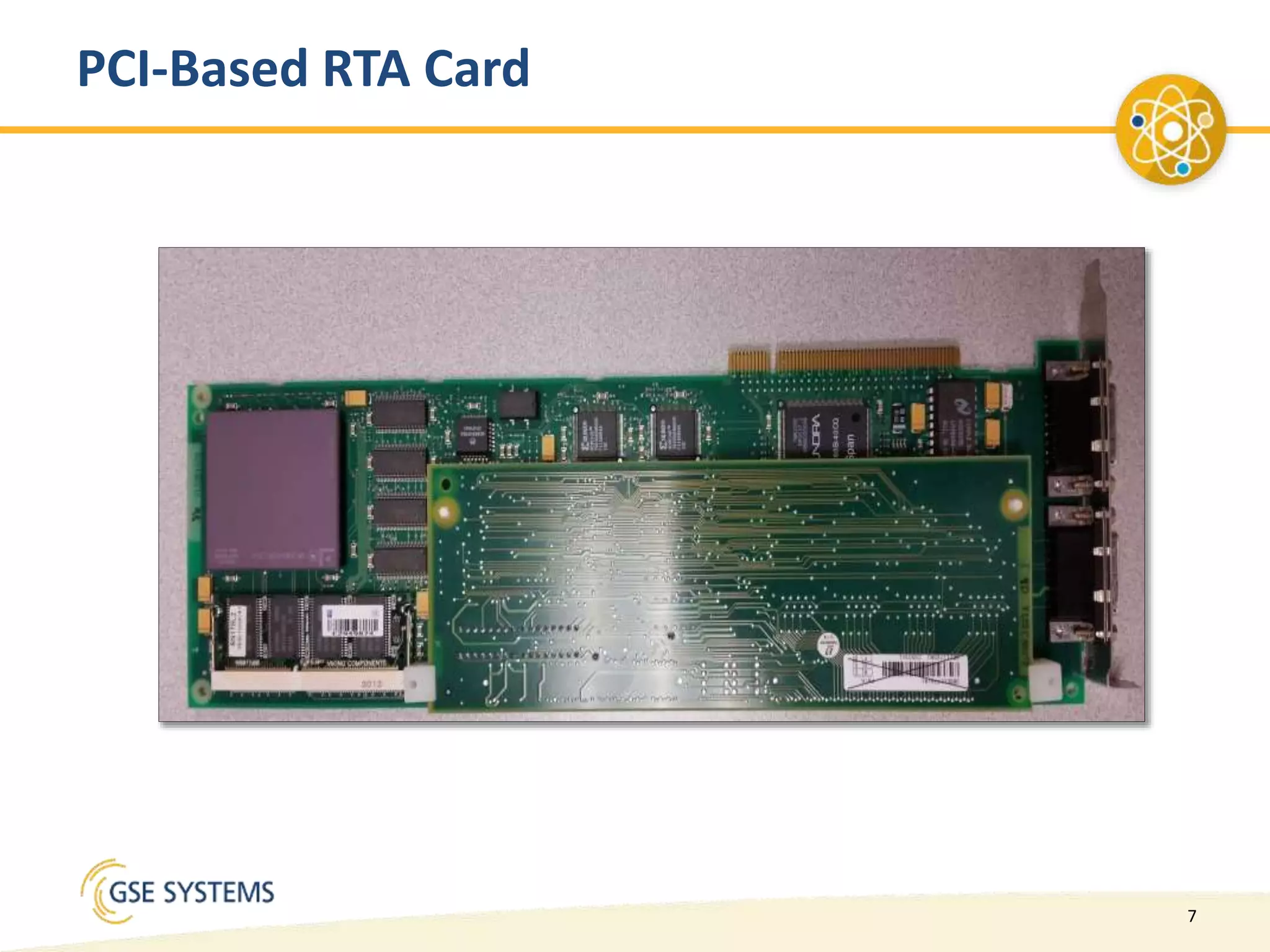

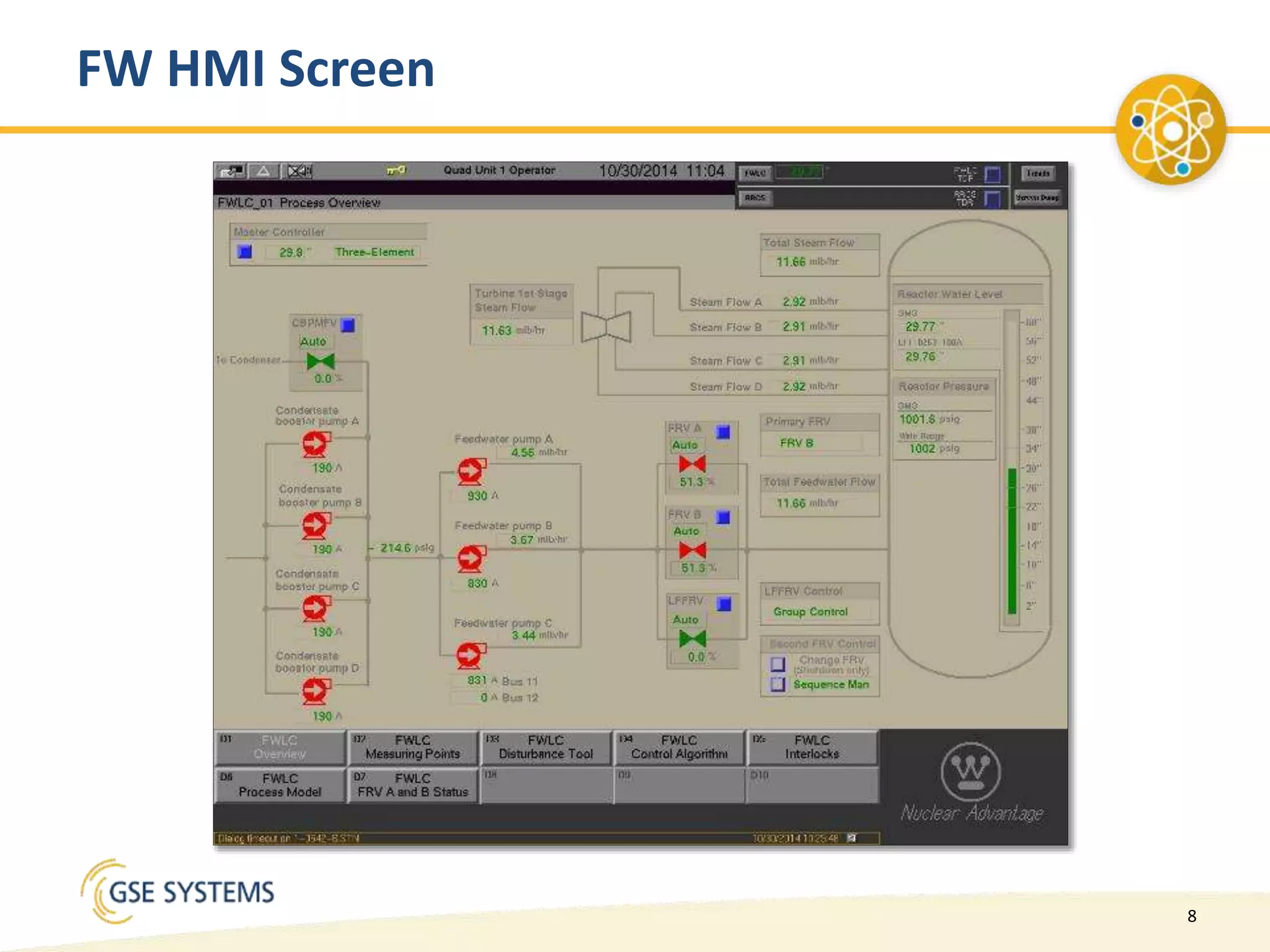

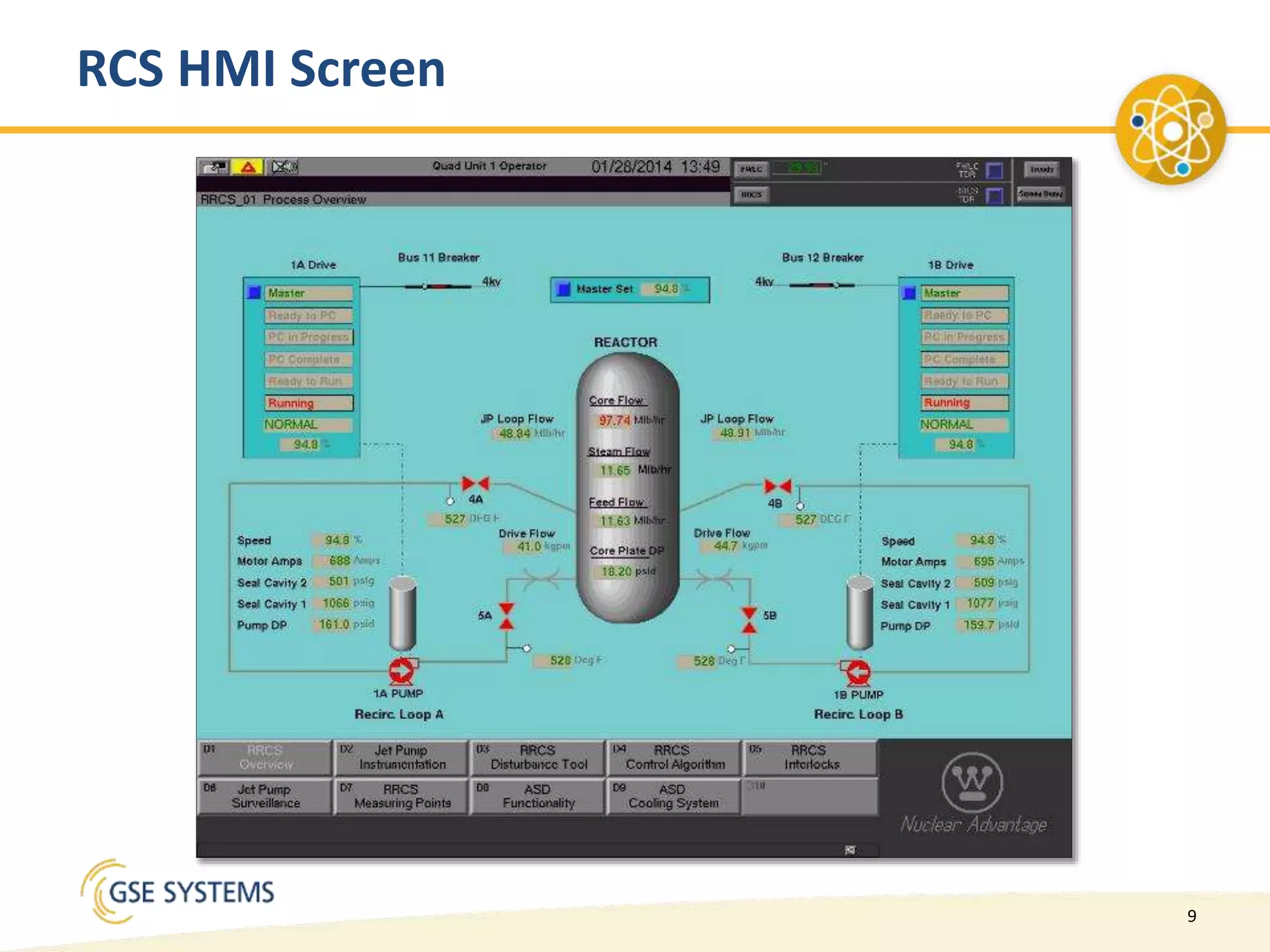

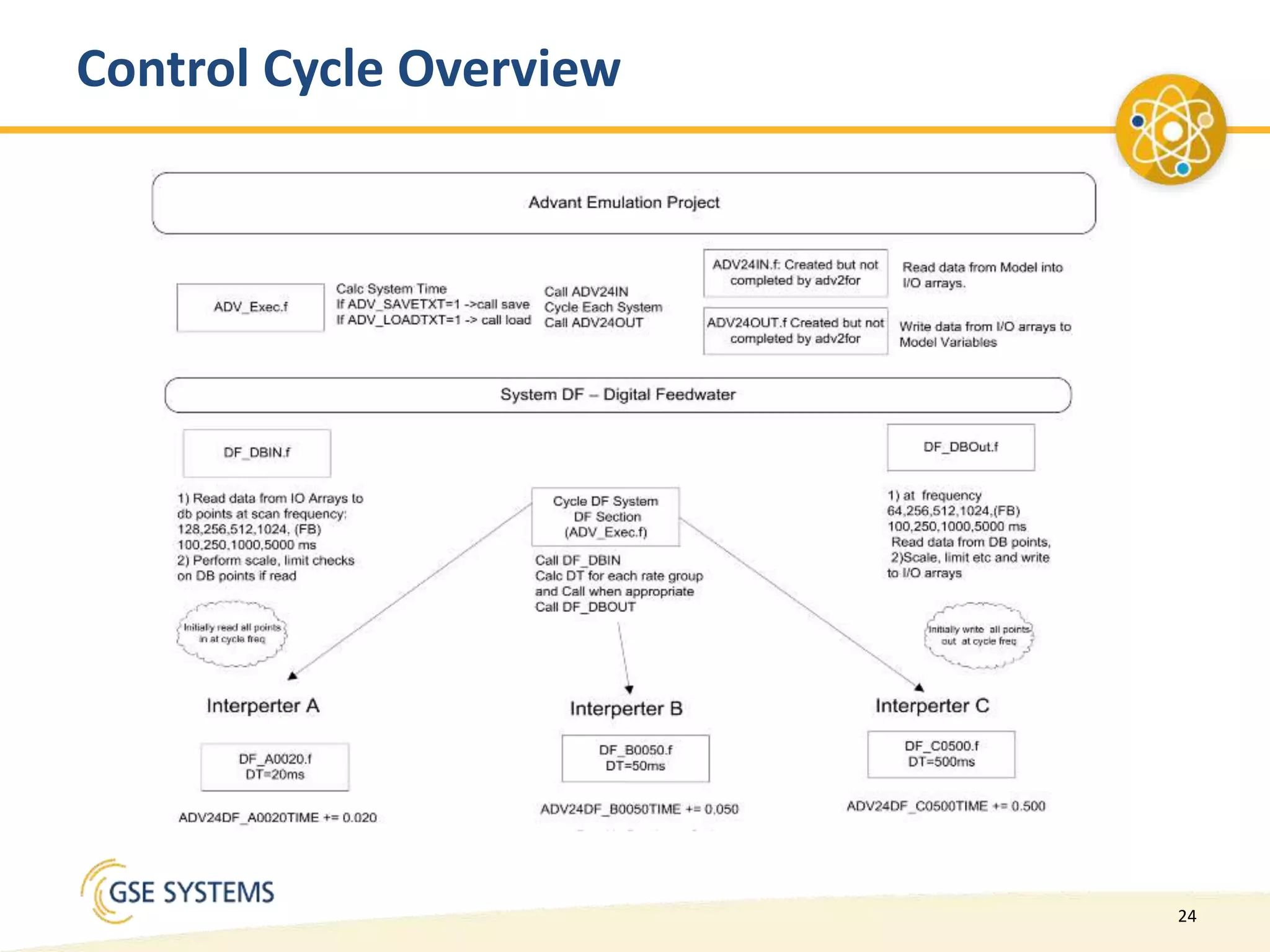

The document details the control and HMI emulation project for Exelon's Quad Cities Plant, focusing on the transition from outdated systems to a new simulator model that addresses compatibility and operational issues. It outlines the project roles of GSE Systems, Exelon, and Nhance Technologies in managing and executing the project, including hardware and software solution development. Key challenges included hardware obsolescence, software incompatibility with newer operating systems, and the need for effective configuration management across multiple testing sites.