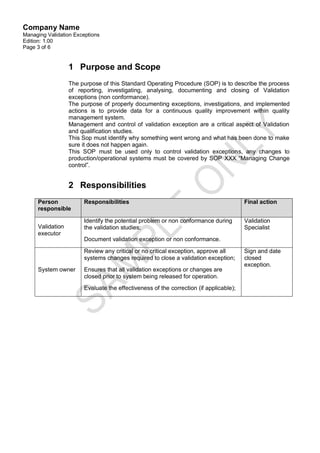

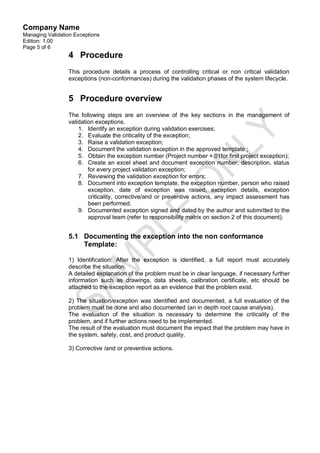

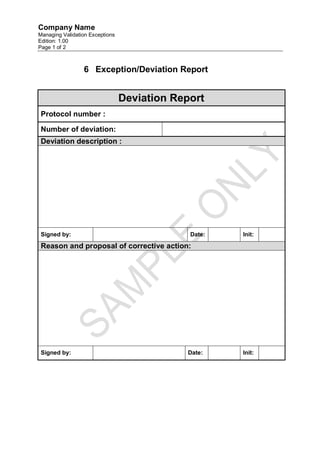

This document provides a standard operating procedure for managing validation exceptions at a pharmaceutical company. It outlines responsibilities for identifying, documenting, investigating, approving, and closing exceptions. The procedure involves documenting exceptions in a non-conformance template, evaluating their criticality, developing corrective or preventive actions, and obtaining approval from relevant parties. The goal is to properly handle exceptions to provide continuous quality improvement and ensure validation studies and systems meet requirements before release.