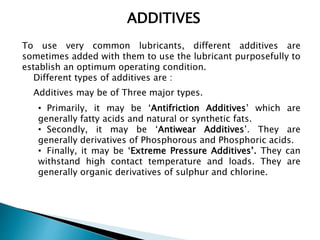

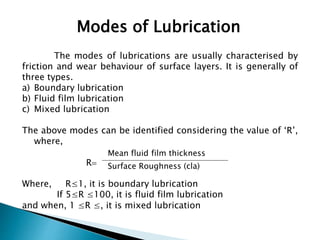

This document provides an overview of lubrication, including different lubrication systems, the functions of lubrication, types of lubricants and their properties, lubricant additives, and modes of lubrication. It discusses hand, dip, wick, splash and circulating lubrication systems. The major functions of lubrication are to minimize friction and wear, carry away heat, and lengthen component lifespan. Types of lubricants include solid, liquid, and semi-liquid like grease. Important lubricant properties include viscosity, flash point, pour point and oiliness. Additives are sometimes added to lubricants to improve performance and include antifriction, antiwear and extreme pressure additives. Modes of lubrication are boundary, fluid