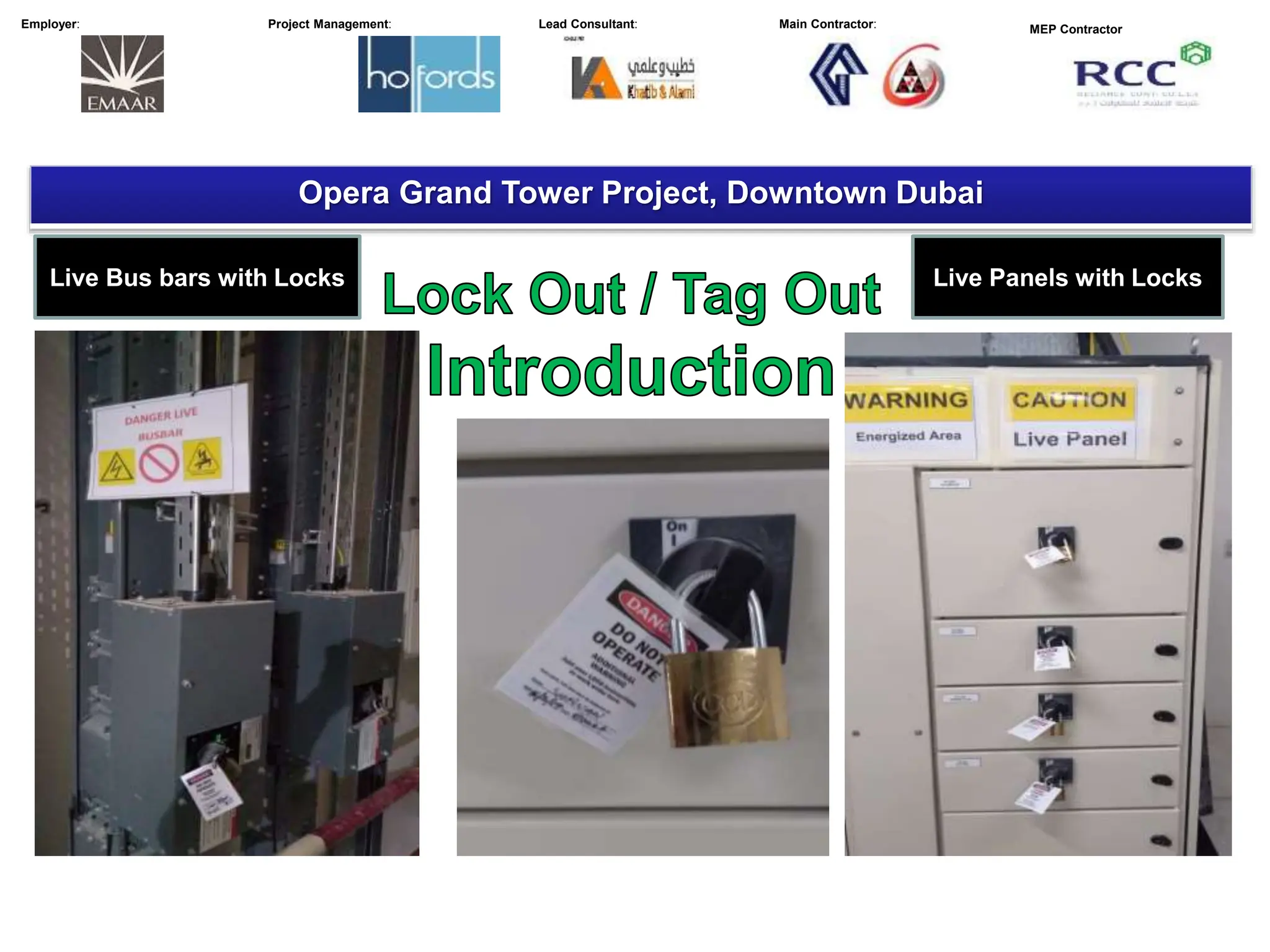

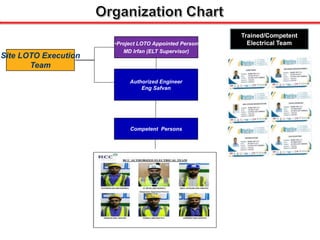

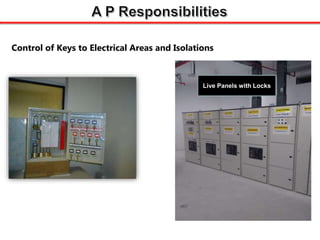

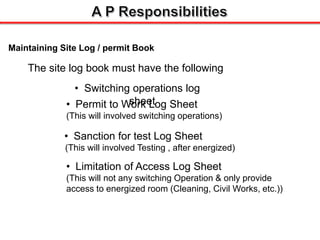

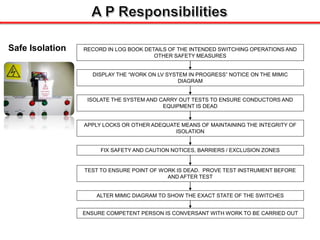

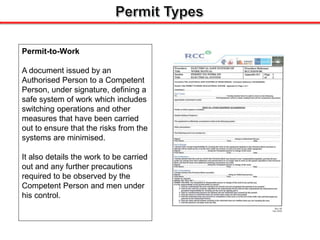

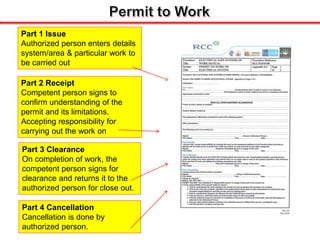

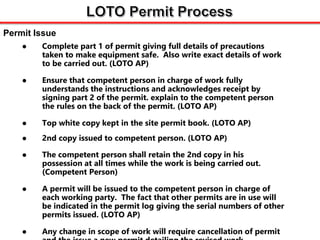

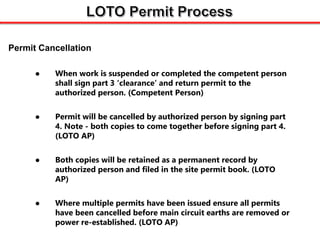

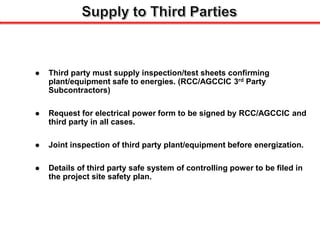

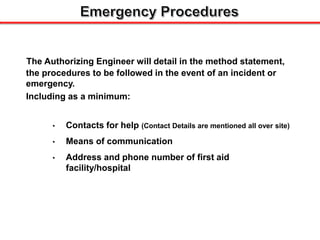

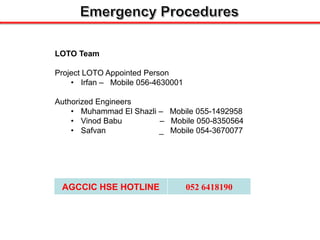

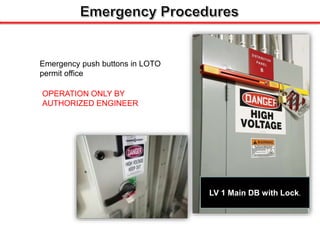

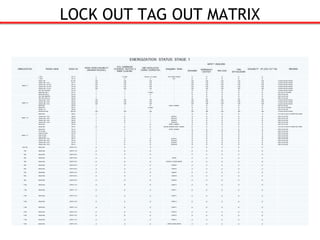

The document outlines lock out tag out (LOTO) procedures for electrical work on the Opera Grand Tower Project in Downtown Dubai. It assigns responsibilities for the LOTO system and describes permit requirements and processes. Key elements include appointing authorized engineers and competent persons, implementing safe isolation procedures before work, maintaining a permit log book, and having emergency response plans and contact details. The goal is to ensure electrical hazards are controlled whenever employees or others could be exposed to risks like electric shock or burns during work.