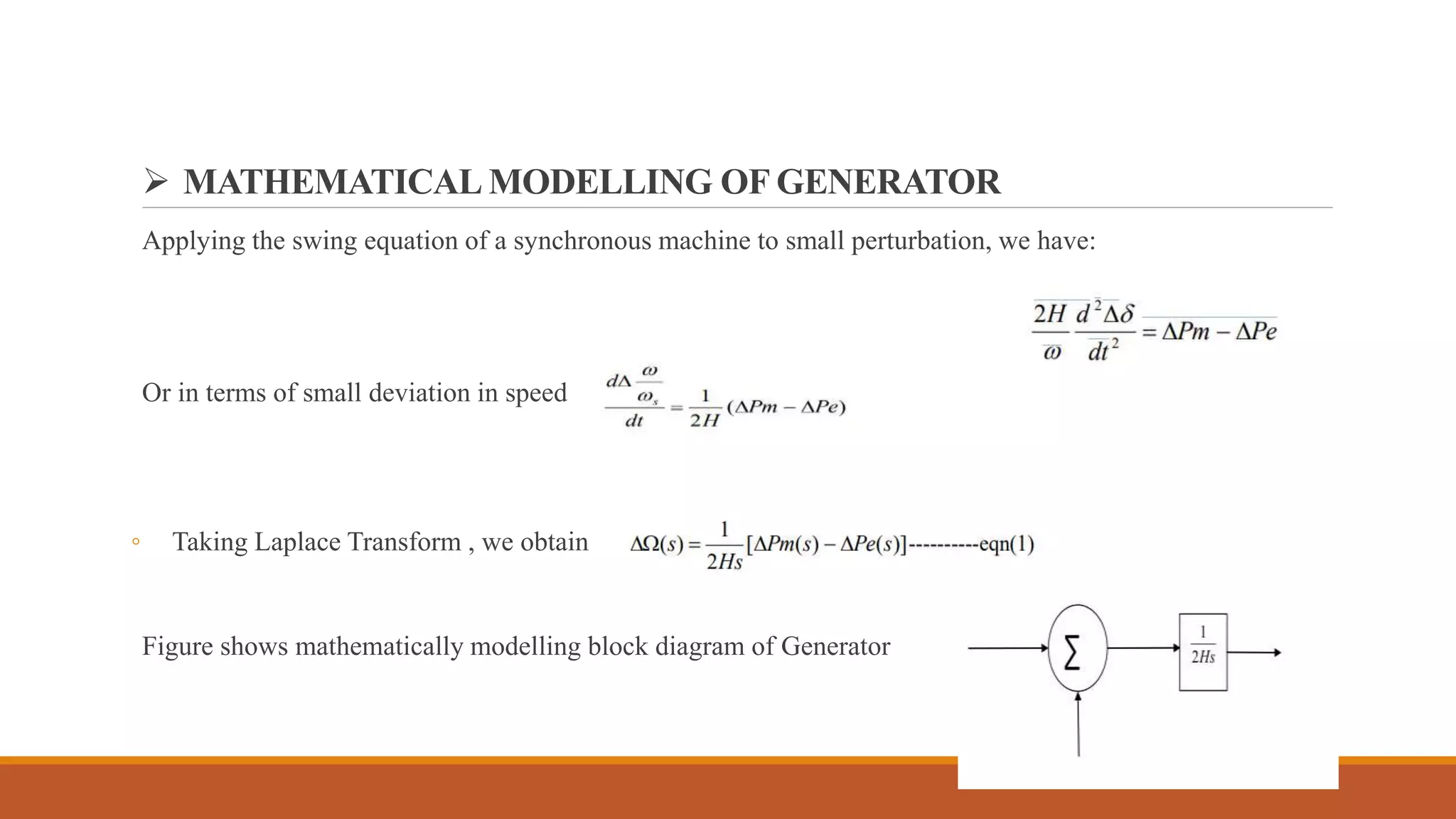

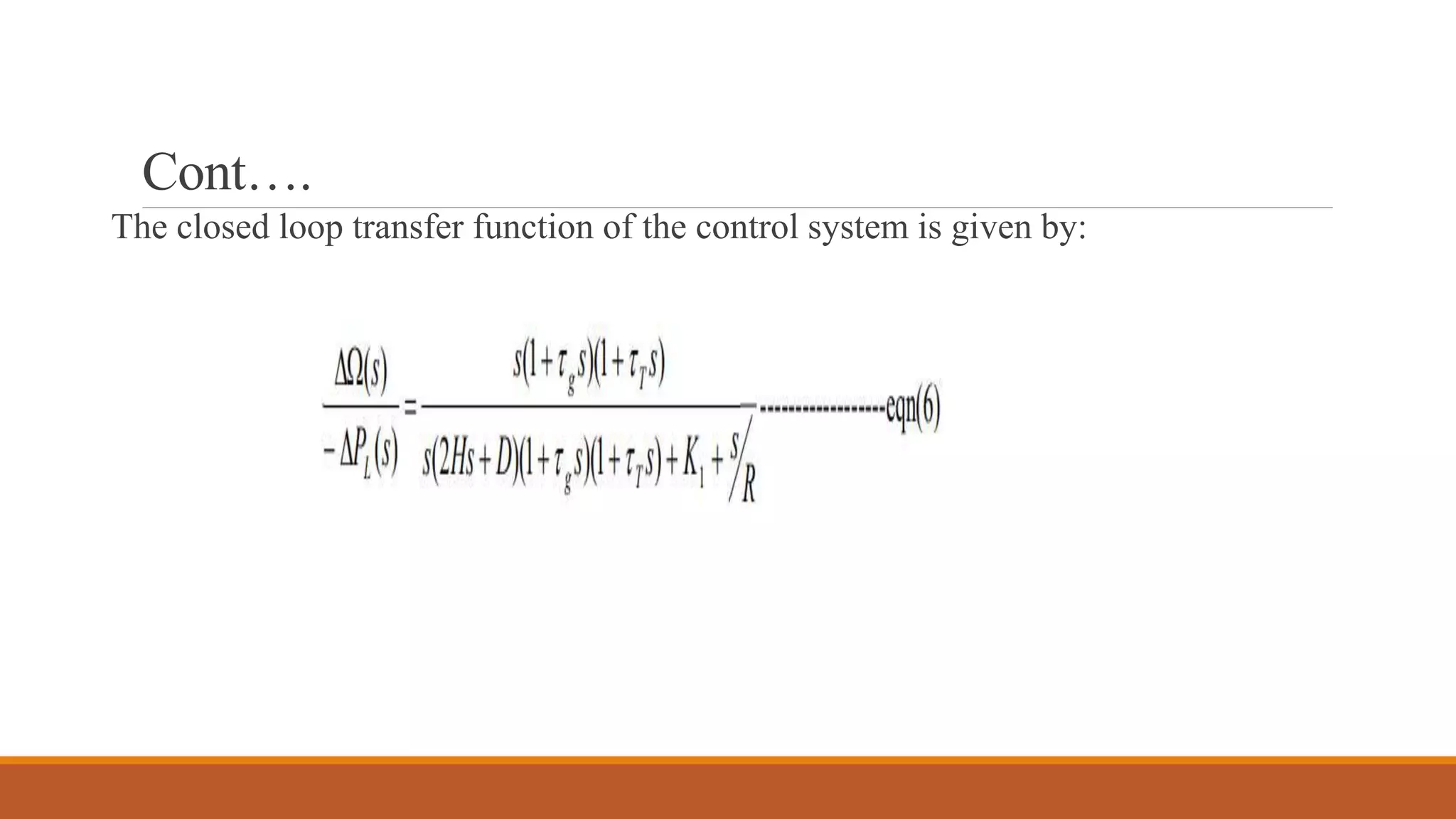

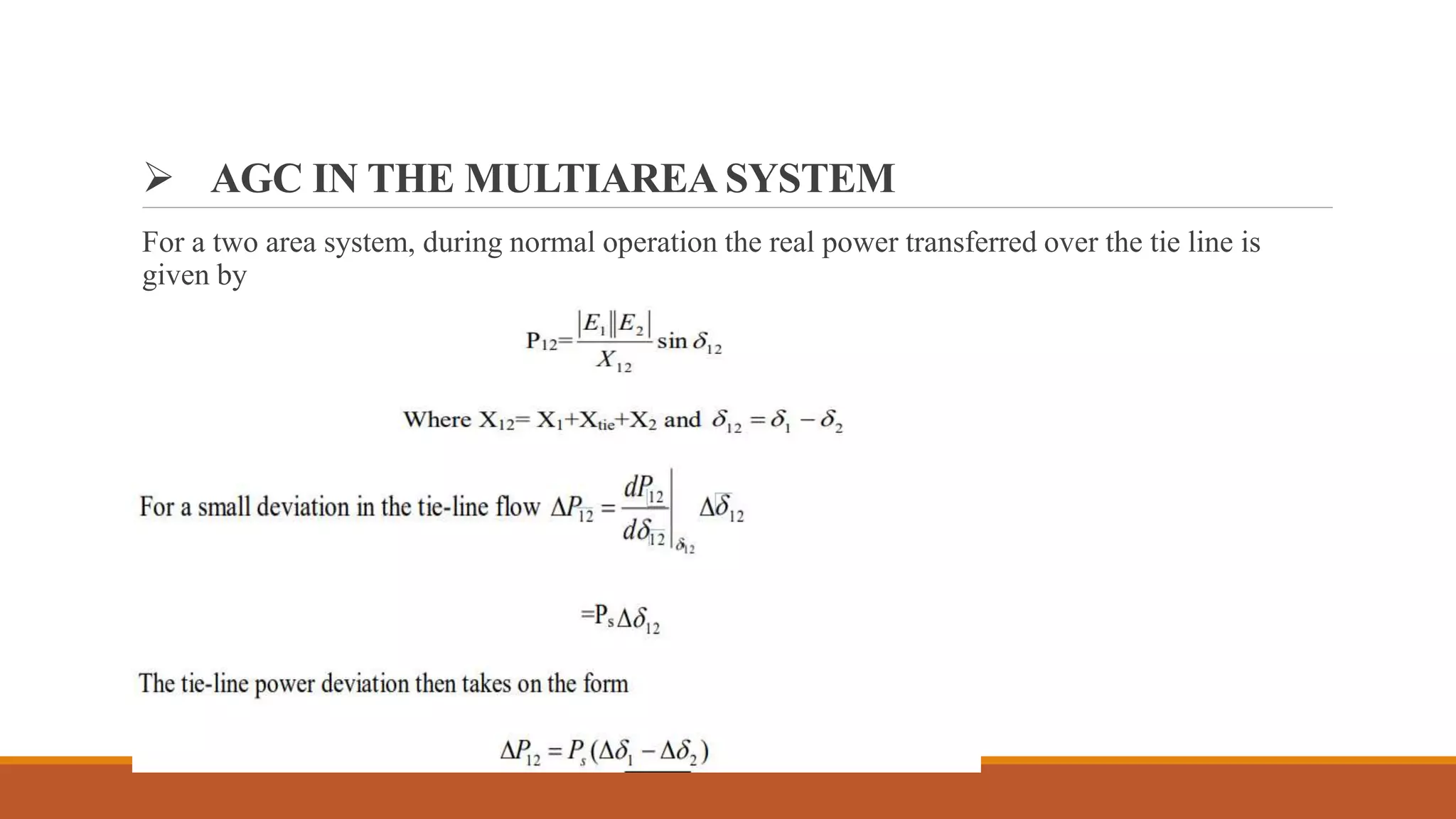

1) The document presents a case study on using electric vehicles to provide load frequency control in an interconnected power system. It discusses mathematical modeling of system components like generators, loads, prime movers, and governors.

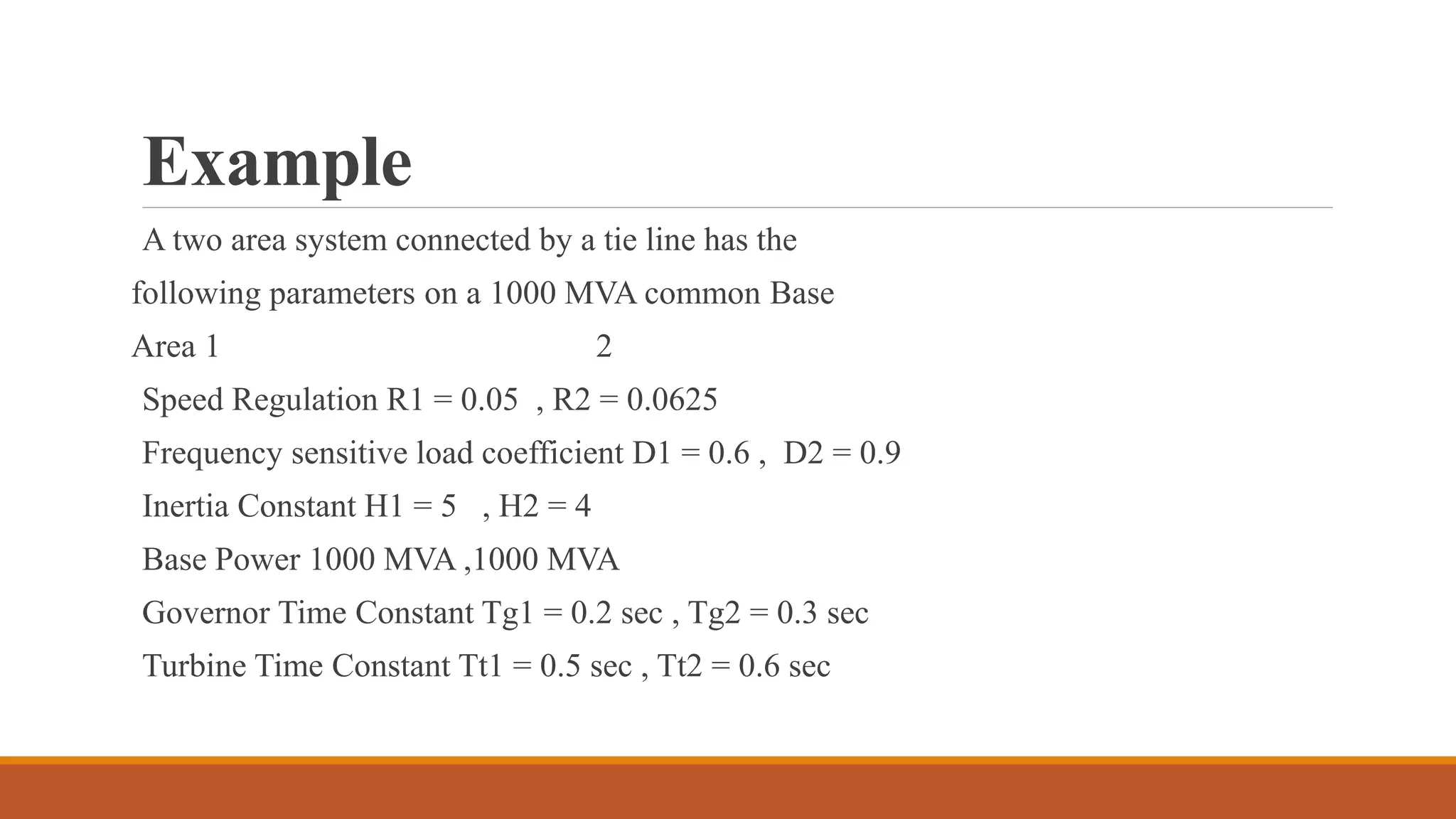

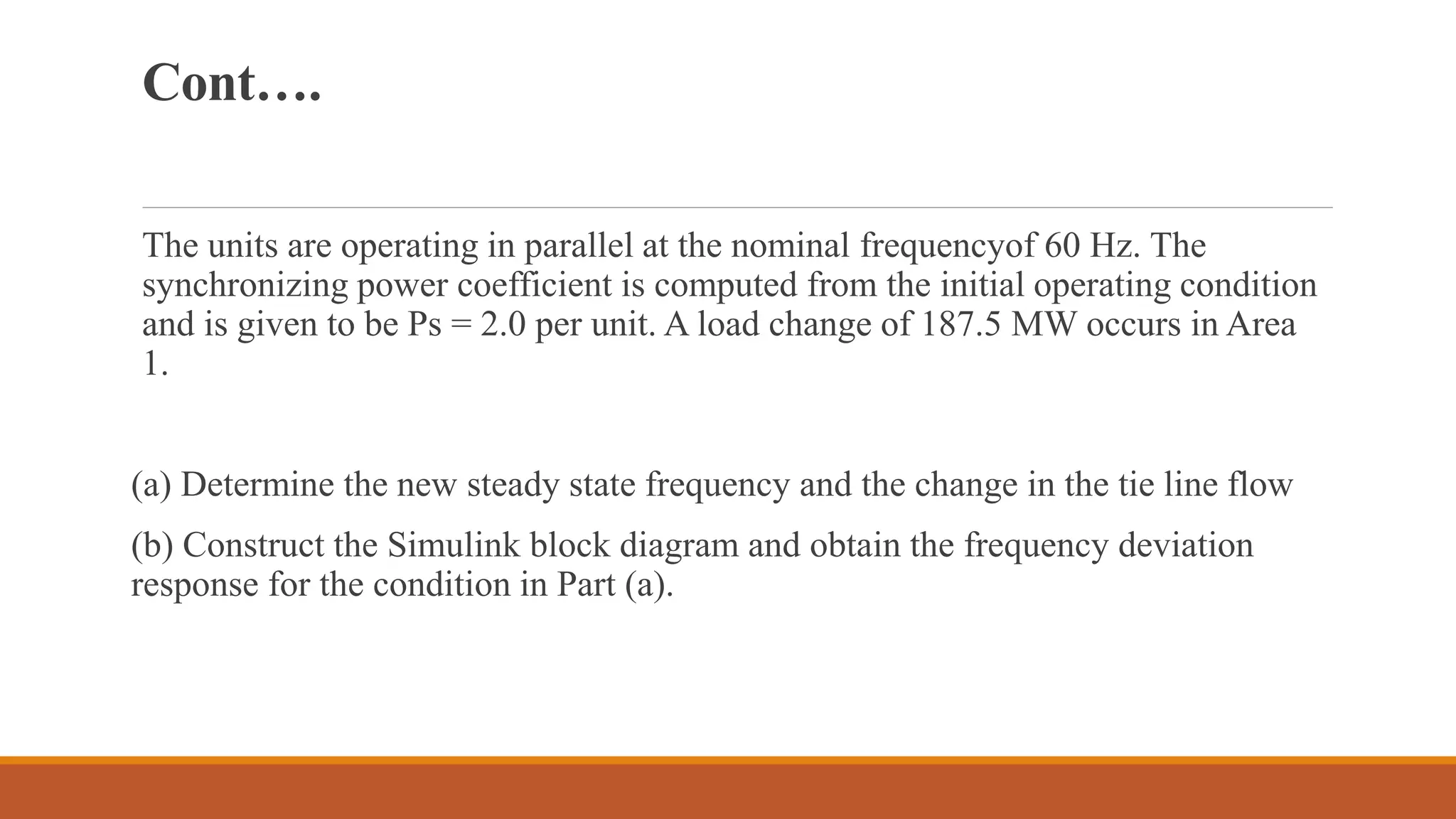

2) The example given is of a two area power system where a 187.5 MW load change occurs in Area 1. The steady state frequency deviation and tie line power change are calculated.

3) Simulation results show a frequency deviation of -0.3 Hz and no change in tie line power for the given load change condition in Area 1. However, practically only the generator in Area 1 should respond, not both generators.