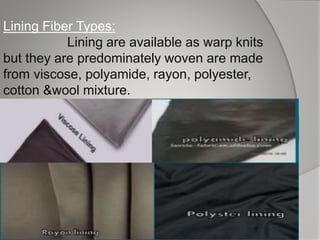

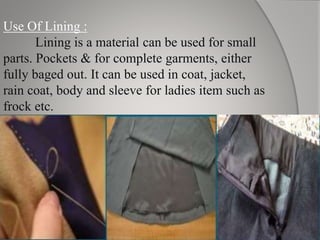

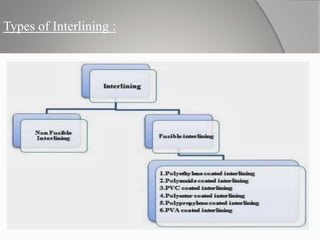

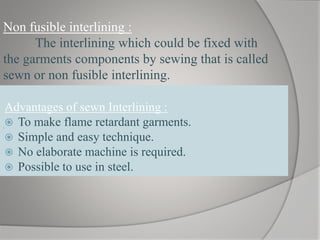

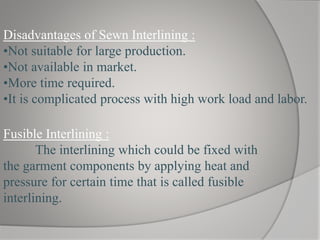

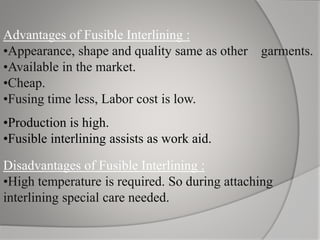

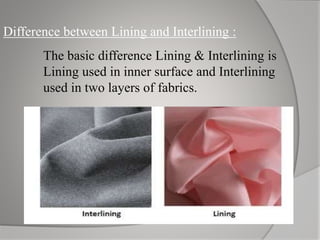

This document discusses lining and interlining, which are commonly used elements in garment manufacturing but can be confusing. Lining is used to cover the inner surface of garments, while interlining is placed between two fabric layers. The document defines each term and discusses the various types of materials used for lining and interlining like cotton, silk, nylon, polyester, and their advantages like comfort and shape retention. Fusible interlining is attached using heat and pressure for quick production, while sewn interlining involves sewing but is simpler. In conclusion, lining and interlining are important for making high quality garments.