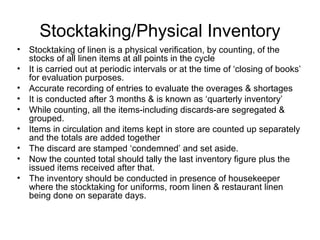

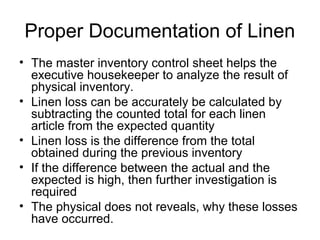

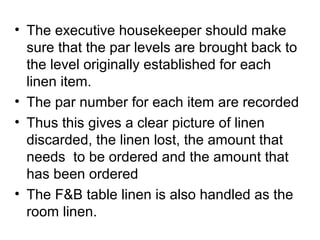

Linen control involves four phases: routine checking of linen appearance and hygiene, quantity control of daily linen flow, periodic stocktaking, and documentation. Key aspects include inspecting fresh and soiled linen for quality; maintaining records of linen distribution, collection, and inventory; and analyzing discrepancies to minimize linen loss. Proper linen control ensures high standards and efficient linen management.