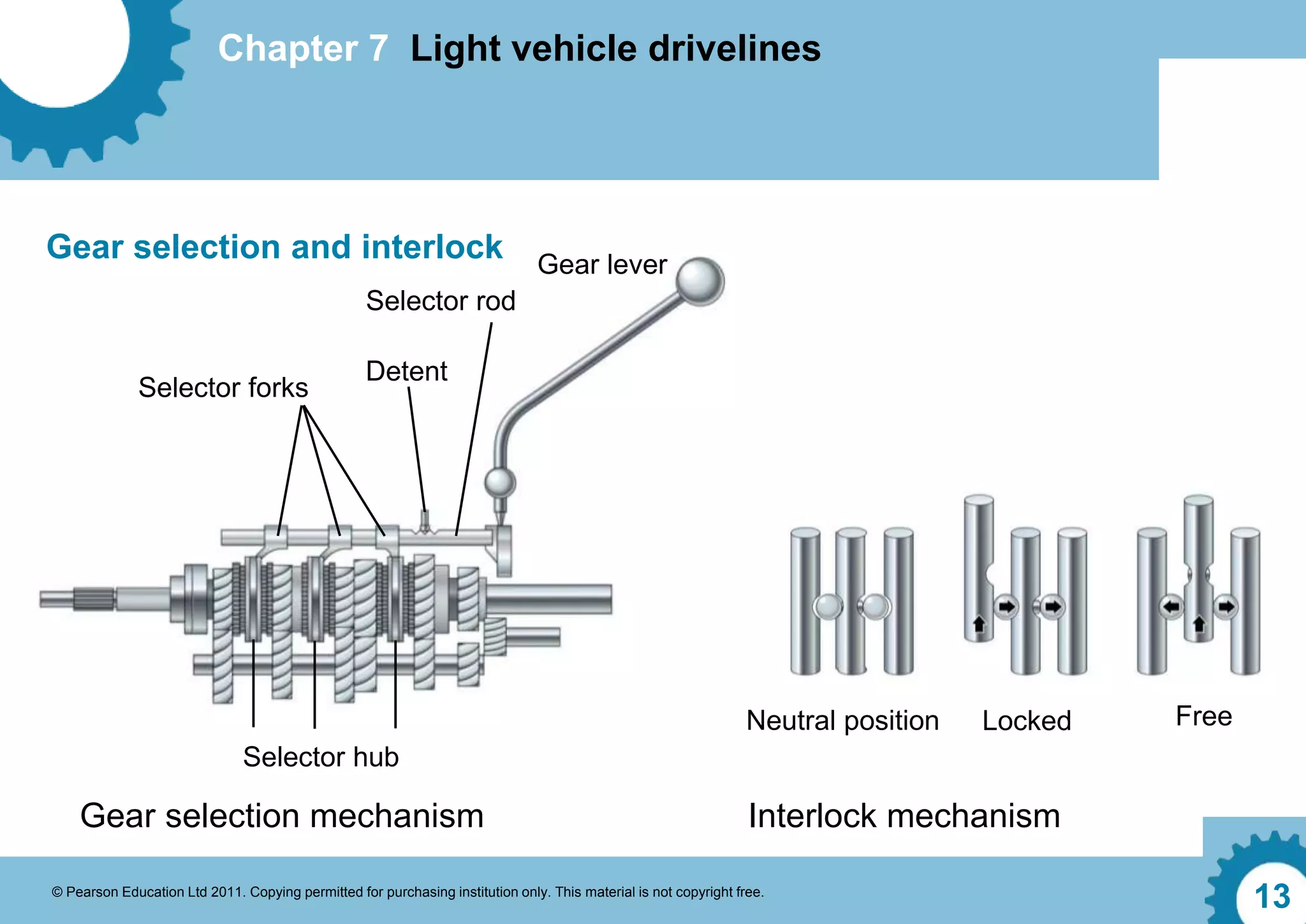

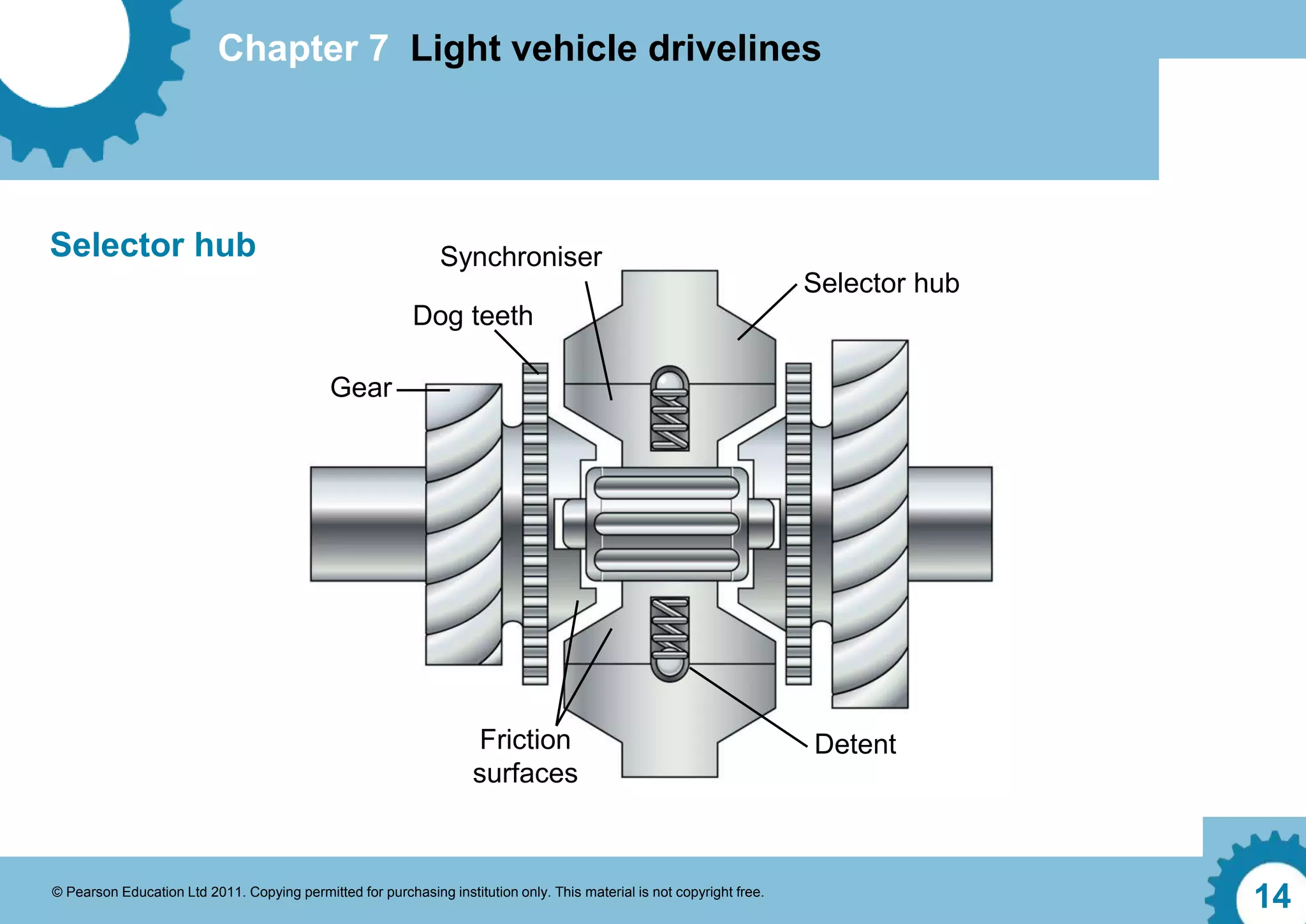

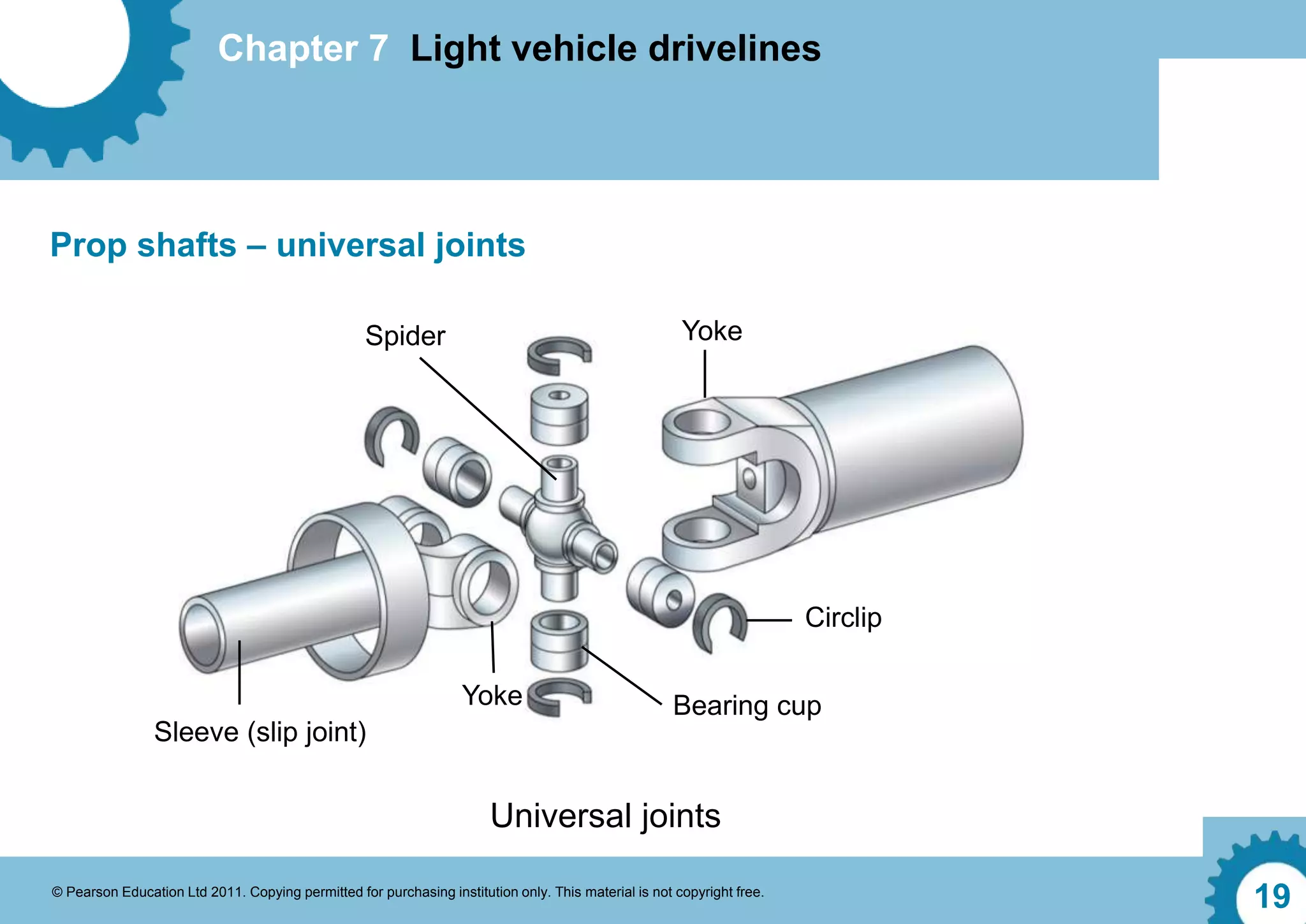

This document discusses the components and layout of light vehicle drivelines. It describes the basic components of drivelines including the clutch, transmission, propeller shaft, differentials and drive axles. It also outlines common driveline configurations such as front-wheel drive, rear-wheel drive and four-wheel drive and how power is transferred from the engine to the wheels in each case. Finally, it discusses how universal joints and constant velocity joints are used to allow for angular movement between the rotating driveline components.