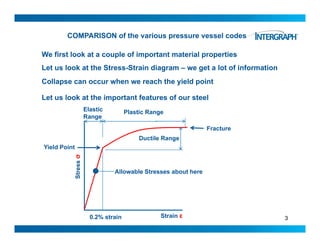

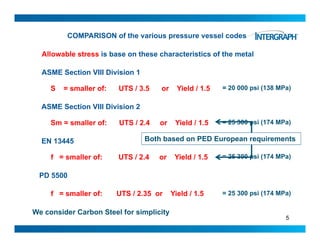

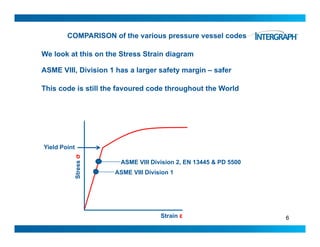

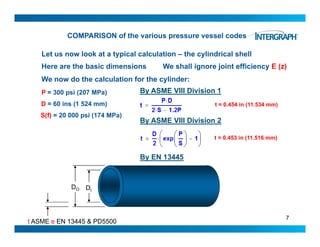

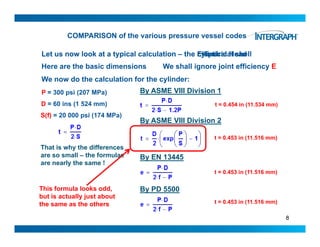

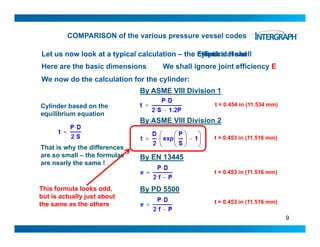

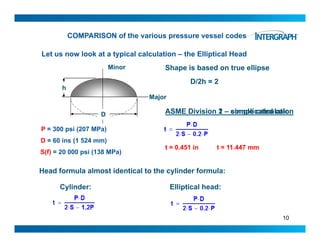

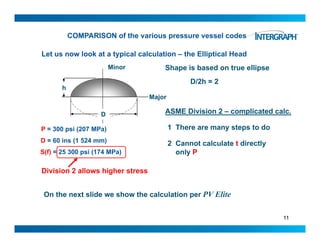

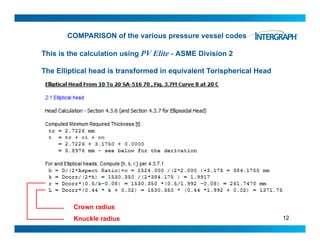

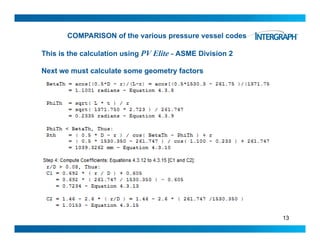

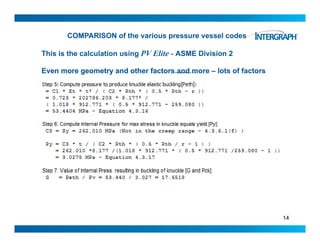

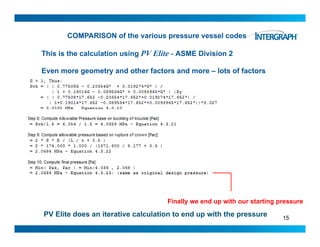

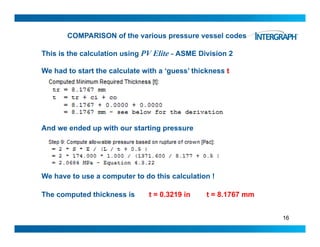

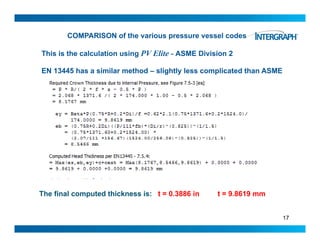

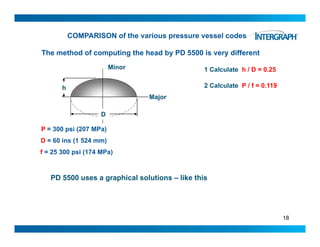

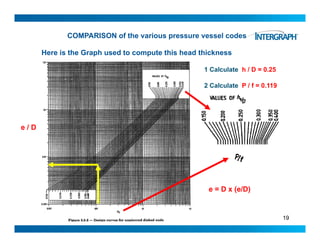

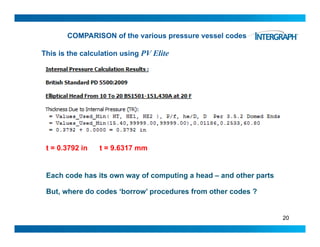

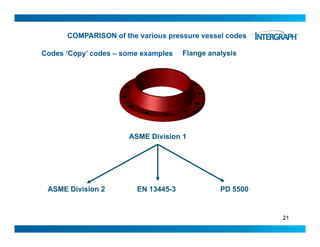

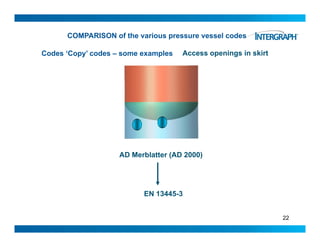

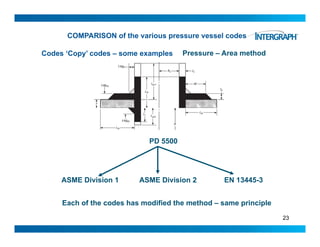

The document compares several pressure vessel codes and how they differ in calculating allowable stresses and vessel wall thicknesses. It finds that ASME Section VIII Division 1 is the most conservative with the highest safety factor, while the other codes allow for slightly higher stresses near the material's yield point. The codes also sometimes borrow procedures from one another, like using similar formulas for vessel heads. Overall, the document aims to explain the approaches in codes like ASME, EN, and PD5500 and how they both differ and align in designing pressure vessels.