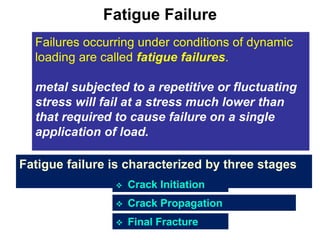

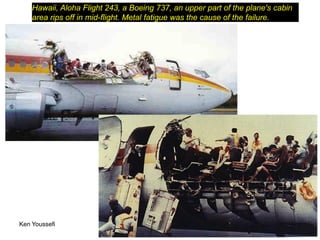

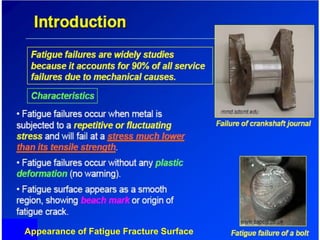

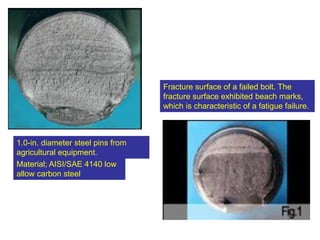

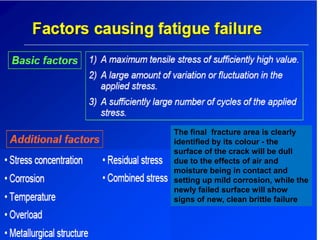

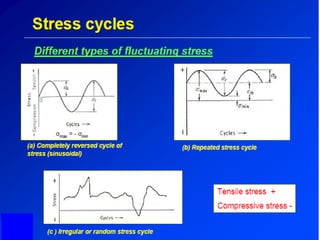

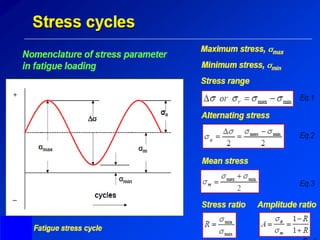

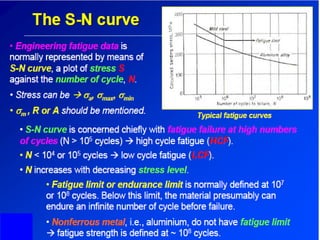

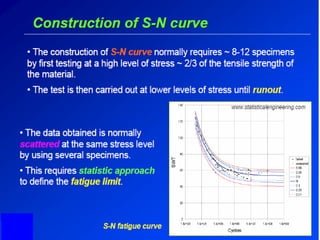

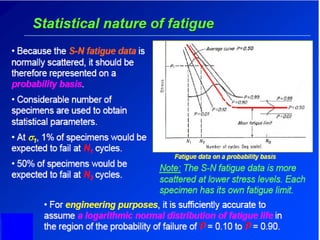

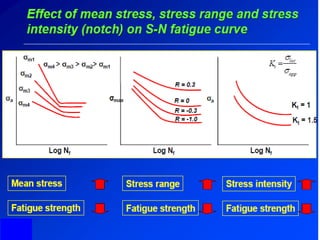

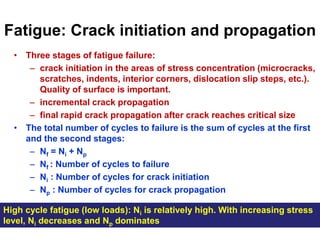

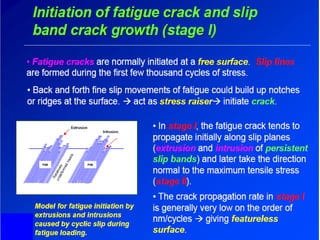

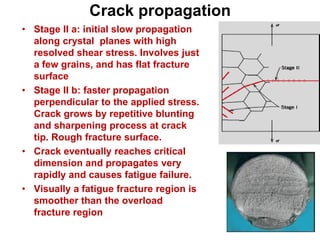

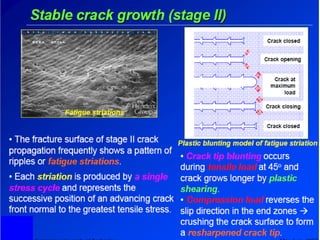

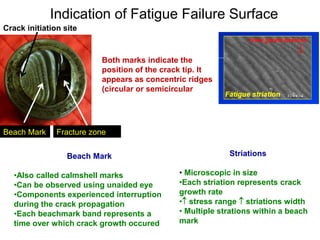

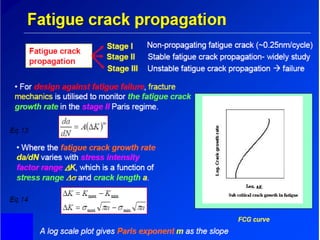

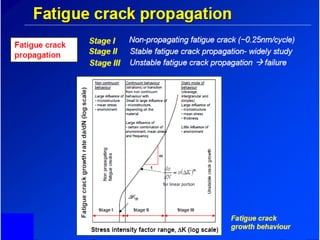

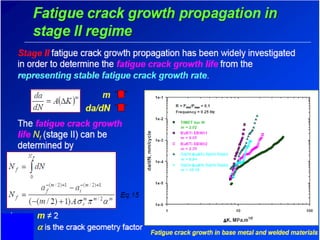

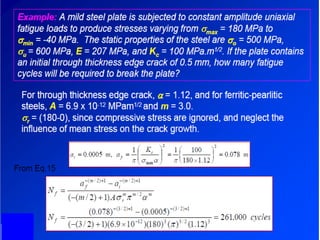

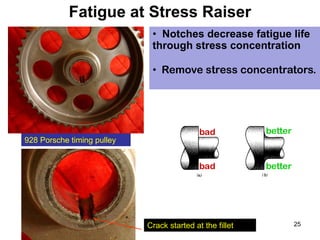

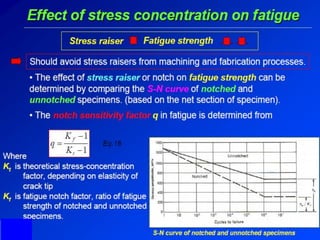

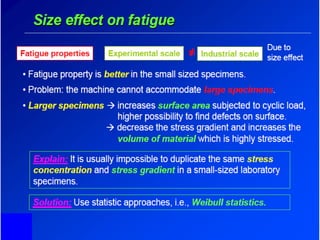

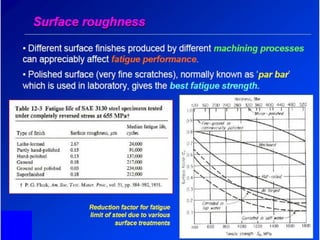

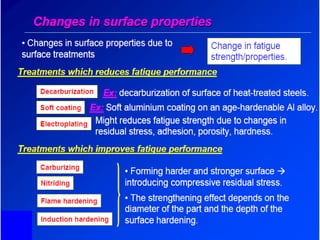

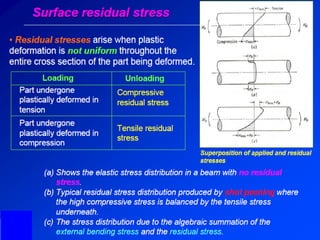

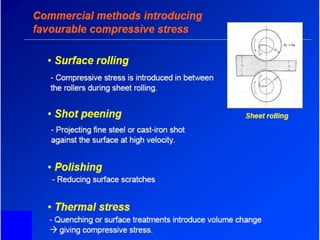

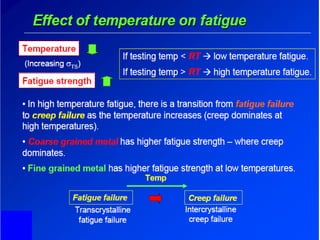

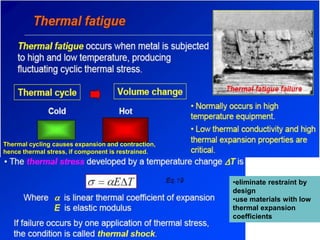

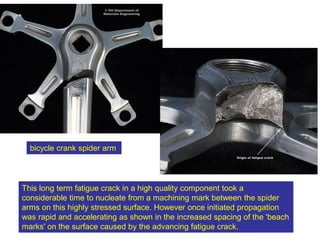

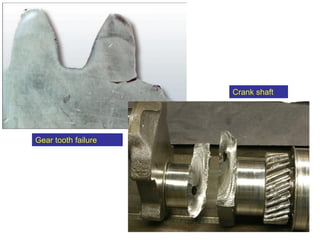

This document summarizes a lecture on fatigue failure. It discusses the three stages of fatigue failure: crack initiation, crack propagation, and final fracture. It describes factors that influence fatigue properties like stress concentrators, surface quality, and cyclic stresses. The appearance of fatigue fracture surfaces is shown, including beach marks and striations which indicate the crack propagation path. Examples of fatigue failures in various components like aircraft parts, bolts, and machinery are presented.