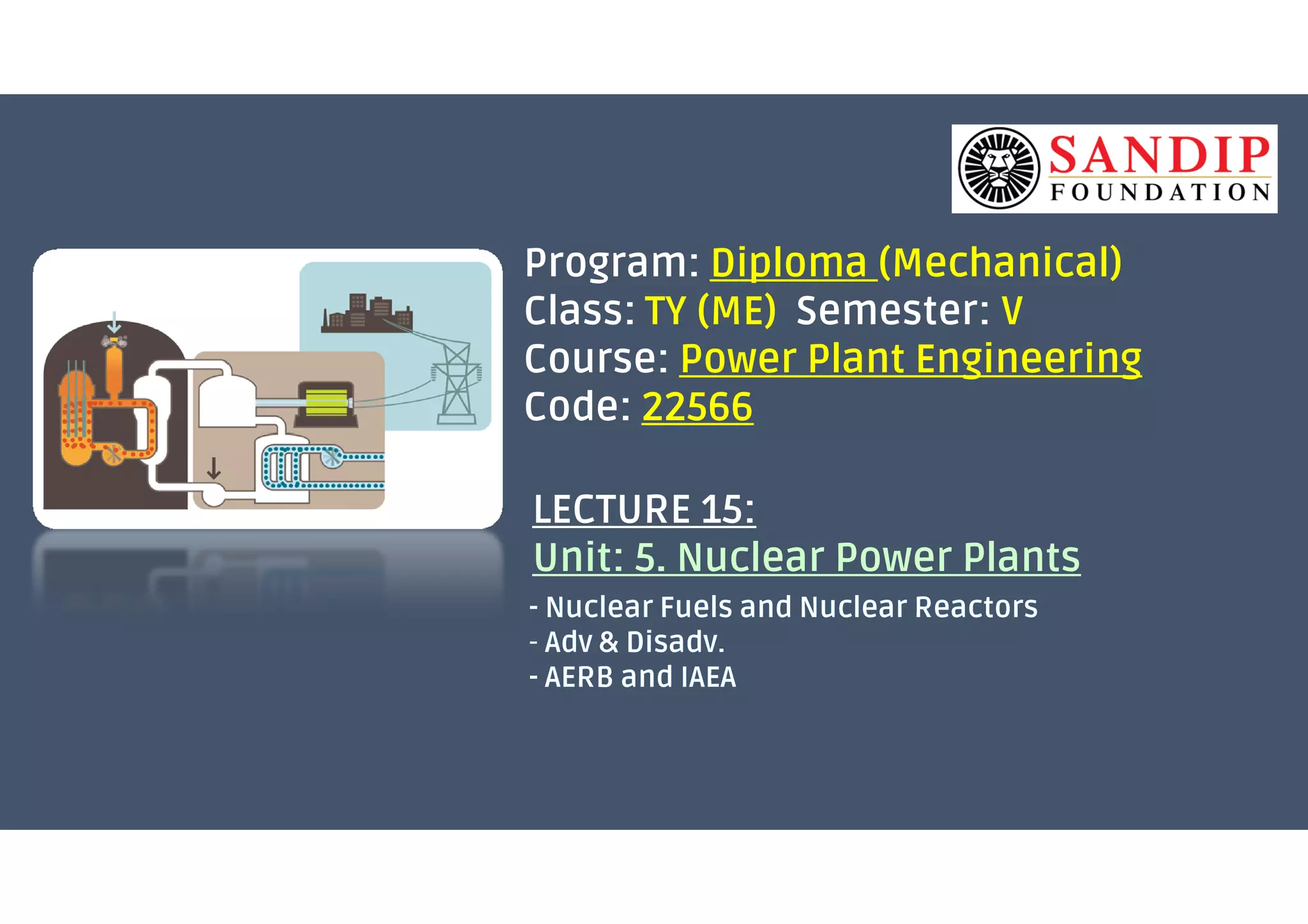

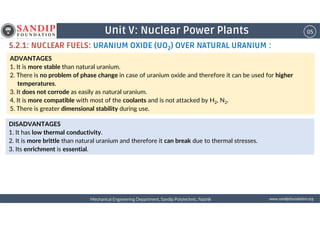

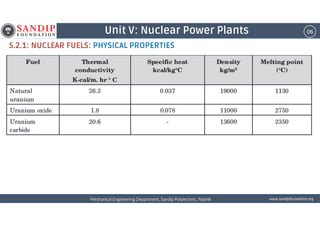

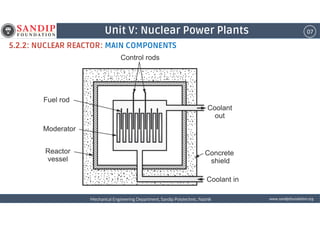

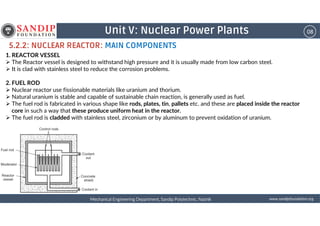

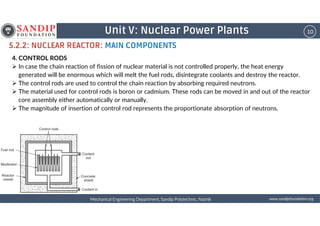

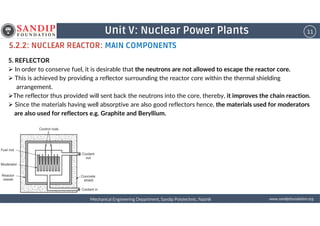

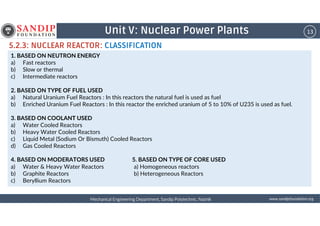

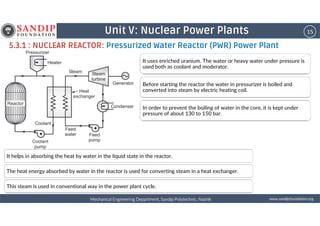

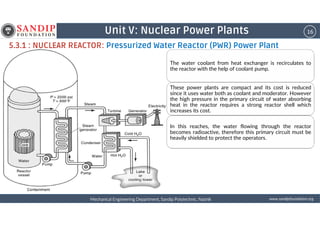

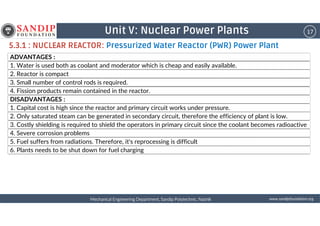

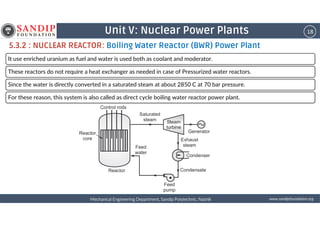

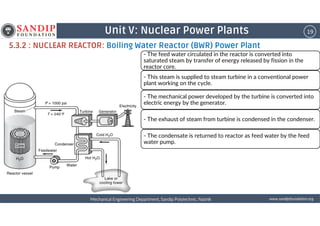

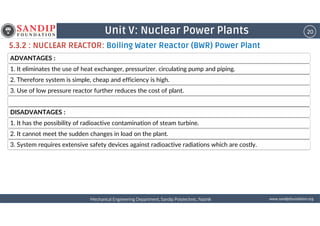

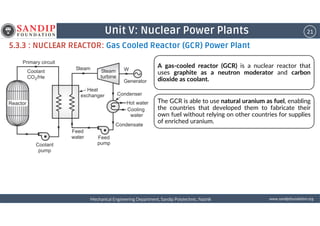

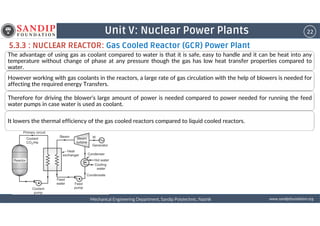

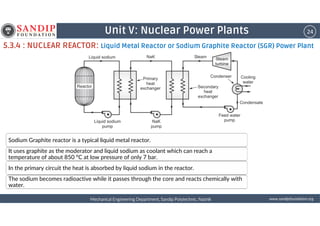

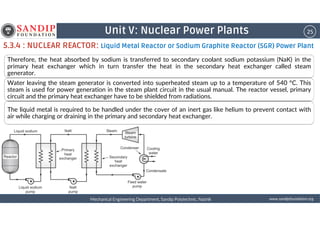

This document provides an overview of nuclear power plants and their components. It discusses nuclear fuels such as uranium oxide and their properties. The main components of a nuclear reactor are described, including the reactor vessel, fuel rods, moderator, control rods, reflector, coolants, and shielding. Nuclear reactors are classified based on neutron energy, fuel type, coolant, moderator, and core type. Examples of nuclear reactor power plants include pressurized water reactors and boiling water reactors. Pressurized water reactors keep water under high pressure to prevent boiling in the reactor core and use it as both coolant and moderator.