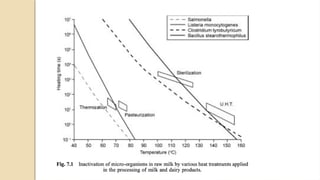

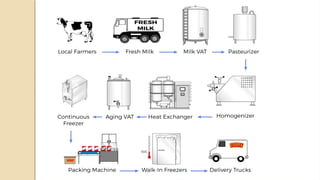

The document discusses the importance of good hygienic practices in milk production and processing, highlighting that milk and dairy products are susceptible to microbial contamination and spoilage. It covers the principal microbial hazards associated with raw and pasteurized milk, emphasizing the role of pasteurization in reducing pathogens but noting the risks of post-pasteurization contamination. Additionally, it outlines the production of heat-stable enterotoxins and the requirements for UHT milk to ensure extended shelf life.