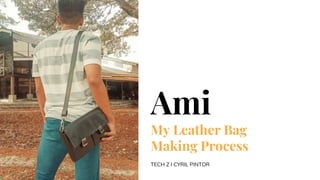

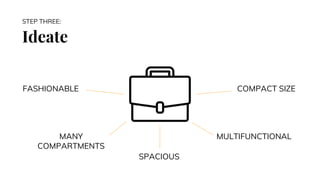

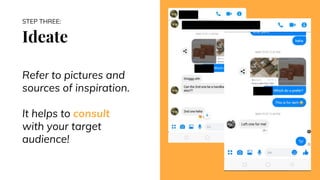

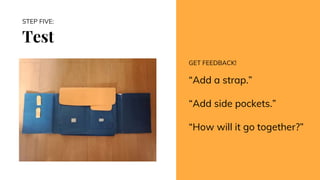

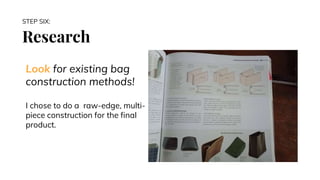

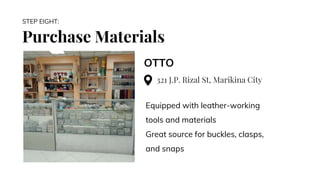

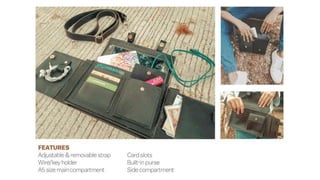

The document outlines a 10-step process for designing and making a leather bag called "Ami". It begins with empathizing with the target audience of students and identifying their need for an organized bag. Through ideating, prototyping, testing, and refining the design, key features of a compact, multifunctional and fashionable bag with many compartments were developed. Materials were purchased and leatherworking and sewing skills were learned to physically construct the bag. Feedback was incorporated and the design process was ongoing.