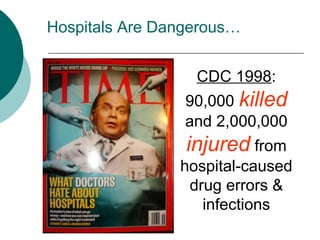

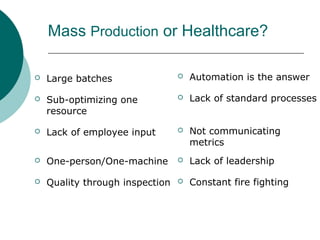

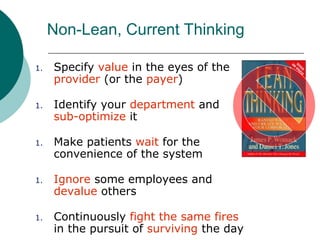

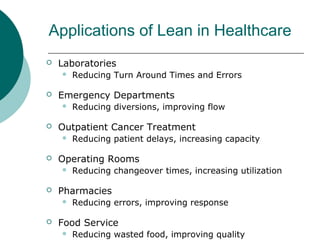

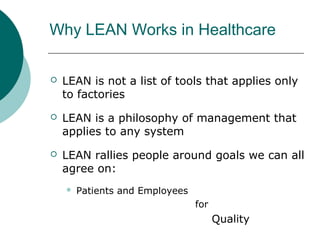

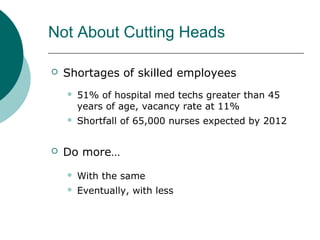

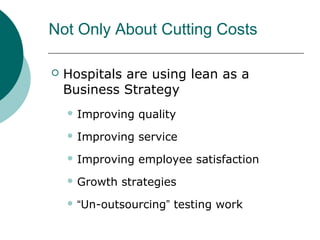

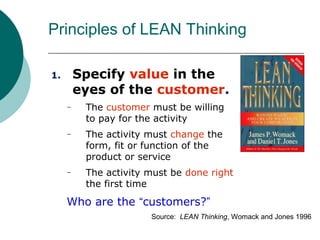

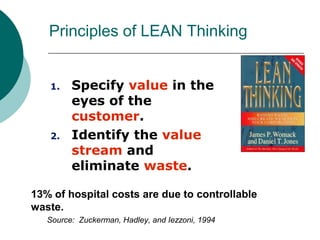

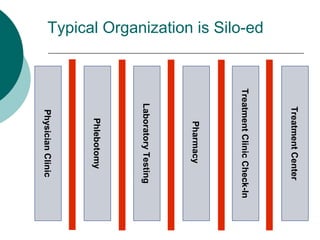

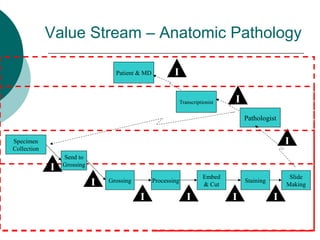

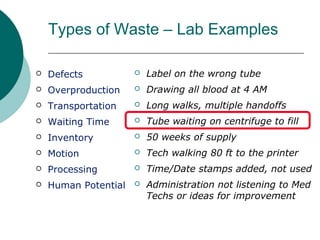

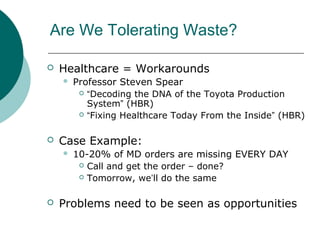

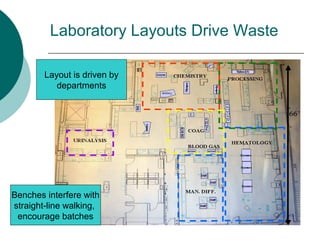

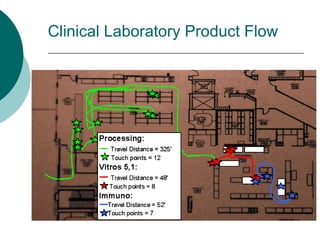

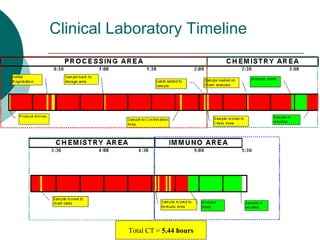

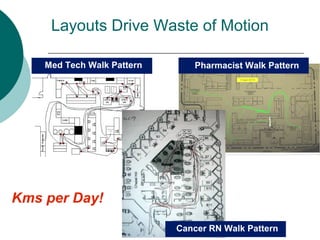

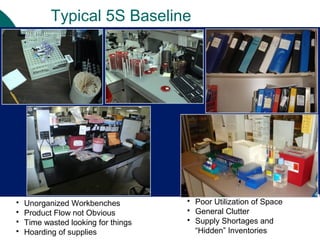

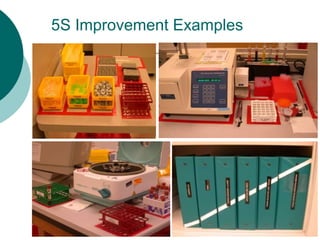

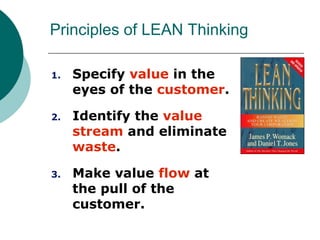

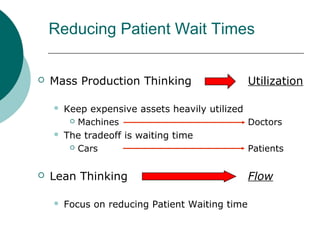

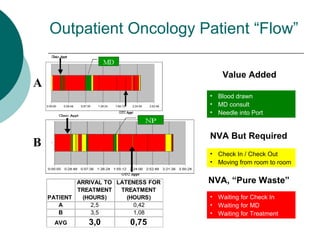

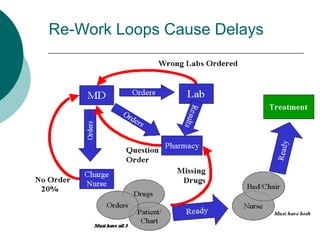

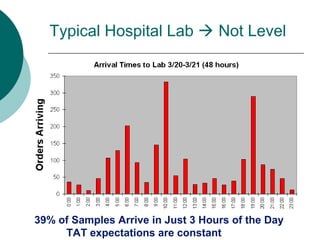

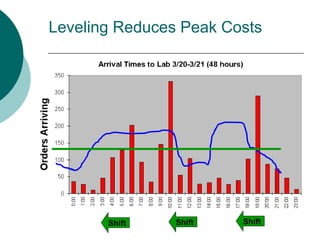

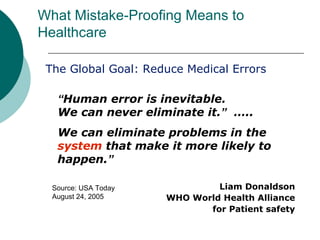

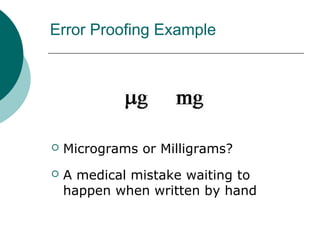

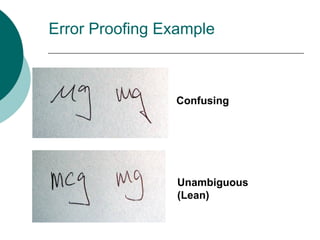

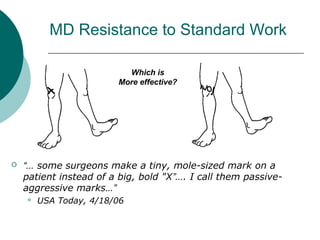

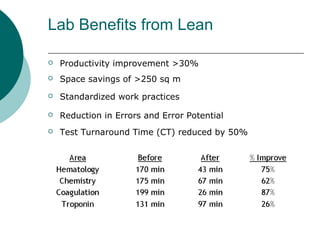

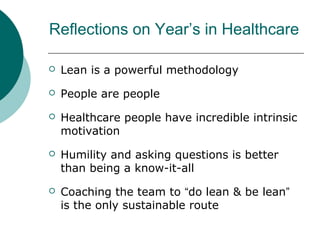

This document introduces lean principles to hospitals. It discusses how hospitals contain a lot of waste that leads to errors and inefficiencies. Lean thinking focuses on specifying value for customers, identifying waste in processes, and making value flow smoothly through pull-based systems. The document provides examples of how lean has been applied in hospitals to reduce errors, improve patient and employee experience, and increase efficiency in areas like labs, emergency departments, and operating rooms. It emphasizes the cultural shift needed towards continuous improvement and employee empowerment.