1) The authors conducted a value stream mapping (VSM) at a medical oncology unit to improve inefficient processes around chemotherapy prescriptions, authorizations, filling, and billing that took two days to complete.

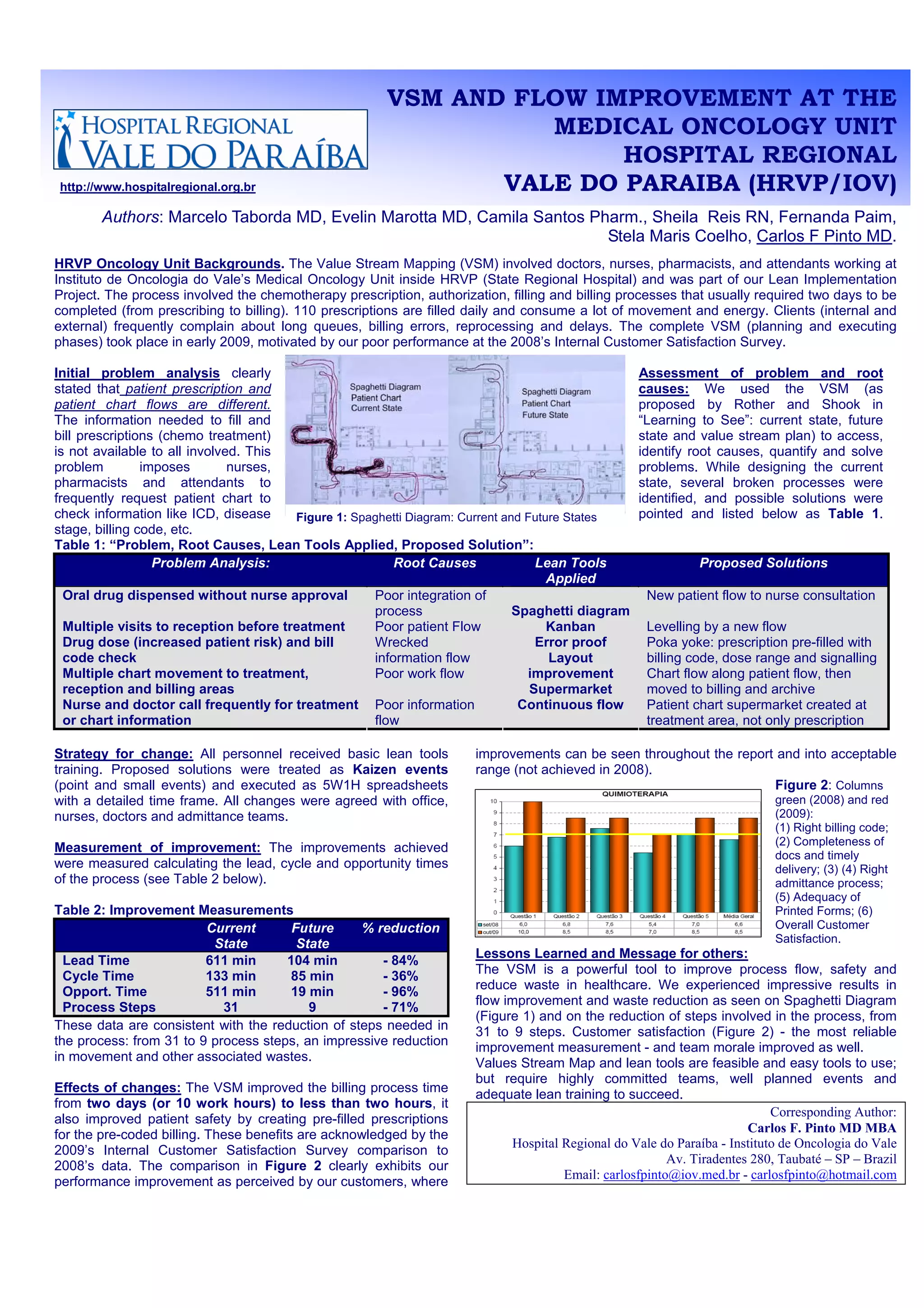

2) The VSM identified problems like poor integration between processes, multiple handoffs of patient charts, and a lack of necessary information available to all involved.

3) Using lean tools like spaghetti diagrams and error proofing, the team proposed solutions like streamlining patient and information flows, creating a patient chart supermarket, and pre-filling prescriptions.

4) Measurements showed an 84% reduction in lead time, 36% reduction in cycle time, and