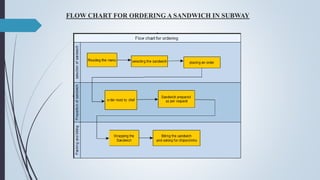

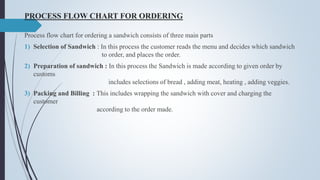

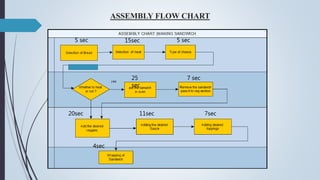

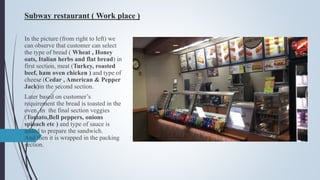

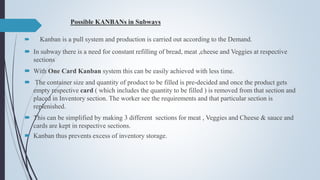

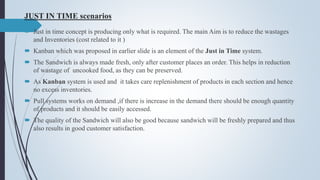

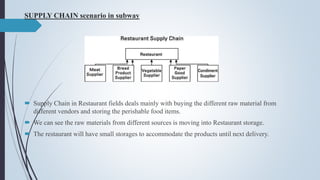

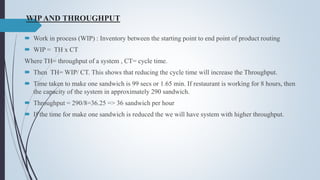

This document discusses the optimization of the sandwich-making process at Subway using concepts such as Kanban, Just-In-Time (JIT), and supply chain management to improve throughput and reduce bottlenecks. Key observations include the identification of bottlenecks during toasting and billing, along with proposed lean process improvements like automatic billing systems and standardization of sandwiches. The conclusion emphasizes the importance of reducing cycle time and implementing modern production strategies for efficiency enhancements in fast-food operations.