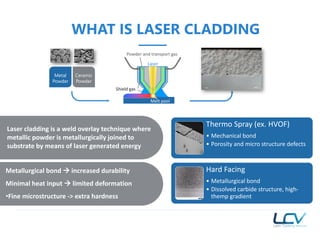

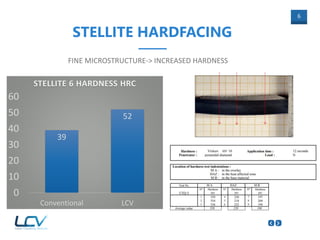

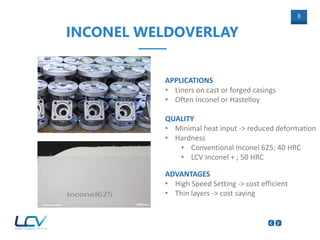

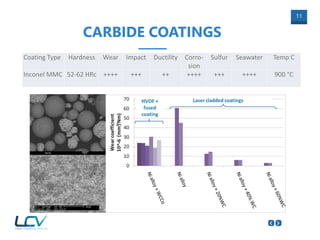

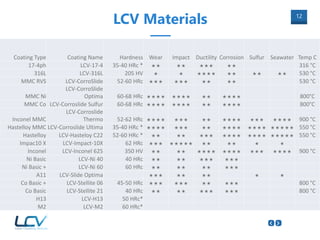

The document discusses laser cladding technology for valve manufacturing, emphasizing the benefits of hardfacing with materials like stellite and inconel, which offer increased hardness, wear resistance, and reduced deformation. It highlights the cost efficiency of thin layers and the scalability of the process for producing high-quality valve components ranging from 1 to 100,000 parts. The document also lists various materials' properties, specifications, and contact information for further inquiries.